With a misconception that printing and digitalisation are opposites, Heidelberg suggests that as of today, the industry is more digital than ever. With around 13,000 machines and systems worldwide connected to the company’s cloud, print shops can benefit from the evaluation of machine data in the form of benchmarking, performance improvements and active machine monitoring.

David Schmedding, chief technology and sales officer at Heidelberg, says, ‘What began 20 years ago at Heidelberg with the connection of the first printing press to the internet has opened up unimagined technical possibilities. Today we are planning the AI-controlled print shop of tomorrow, which can run shifts autonomously at comparatively low cost. And Heidelberg will provide important building blocks for this with software, machines and robotics.’

Since 2004, Heidelberg has invested hundreds of millions in digitalisation, data technology and robotics. 2004 marks a significant milestone for the company, as the year that kick-started the era of smart manufacturing, connecting Heidelberg presses to the internet. This was made possible by sheetfed control – the fully digital control unit. At the same time, the Heidelberg Cloud was launched as a platform for remote maintenance and digital services. This was an important milestone after the introduction of Prinect software (2000), which networks all machines and systems in a print shop into one workflow.

Moving on to 2008, this year signified the first use of a press’s performance data, one of the initial elements for consulting, benchmarking, and performance contracts.

In 2016 there was a full paradigm shift as fully automated production from prepress through to printing was made possible. The company also launched Heidelberg Assistant: The online application shows key performance indicators and services at a glance (now part of the Heidelberg customer portal).

The next milestones for the company were 2017 and 2020, with Heidelberg presses, consumables, training, and consulting becoming available via a contract-based subscription in 2017. By 2020, robots were introduced by the company with the StackStar P – an industrial robot that deposits stacks of folded print sheets on a pallet. With plate to unit and the Prinect Scheduler, printing plates can now reach the press automatically.

In 2021 the company launched the PAT (performance advisor technology) AI tool: provides contract customers with straightforward recommendations for action in their print shops (now part of the Heidelberg customer portal). This technology expands the press’s existing AI functions.

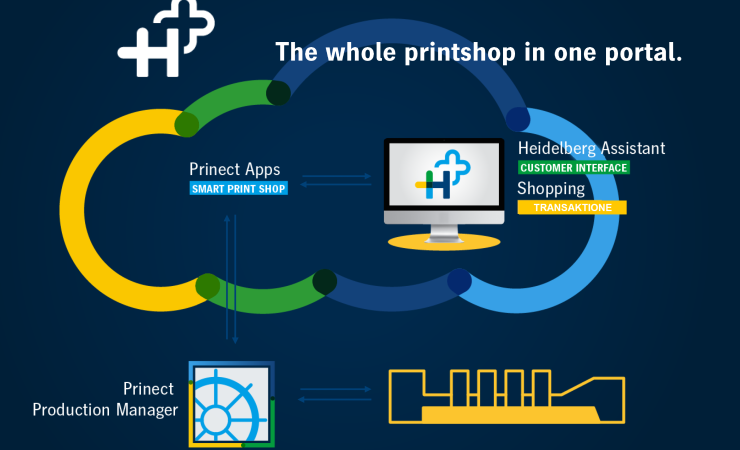

Two years later, in 2023, it was the year of expansion as Heidelberg adds more to its cloud service and, with its new customer portal, now offered all digital services from a single source.

Since the drupa 2024 trade fair, Mr Schmedding says Heidelberg is well equipped for the future and is currently benefiting from a high order backlog following the show. Heidelberg claims it has been a total solution provider for print shops and offers all modern printing processes with corresponding machines – from toner to inkjet, from offset printing to flexographic printing. Following drupa, further developments in Heidelberg’s technology include the new Jetfire 50, offering digital printing with inkjet technology and, thanks to Prinect, can work in conjunction with offset presses. The new Peak Performance generation Speedmaster XL 106 offers even better performance thanks to cloud functions and benefits from even more AI software. The new StackStar C coexisting robot does not require a safety fence and is able to work directly alongside people on postpress operations for print products.

Looking ahead, the company looks to further influence the digitalisation of print. The next version of the Prinect workflow software is already in the starting blocks with the new AI-based version Prinect Touch Free. The cloud application will decide for itself which printing process (offset or digital) is the most efficient and cost-effective production method and then independently calculate all possible layouts on the print sheet. With these technical prerequisites, the AI-controlled printshop of tomorrow is the next achievable step.

Mr Schmedding concludes, ‘Our company has shaped the printing industry over the past 20 years and far beyond, and will continue to do so in the future based on our technological expertise.’