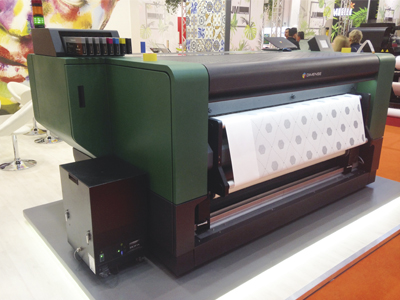

The Dimense printer by Veika allows fully variable embossed

wallpaper printing

Billed as the “most international Fespa yet”, May’s wide-format extravaganza showed an industry in rude health. Michael Walker tramped the aisles to see what was new.

For all that it doesn’t look that huge on the outside – a block’s worth on one side of the road and less than that on the other – you can walk a long way inside the Hamburg Messe in a couple of days. But the effort was well-rewarded, with a buzzing atmosphere and sense of purpose that not all trade shows manage.

It helps when it’s a wide-format show, of course, because there are so many large and eye-catching examples to look at. Not all of them are on paper, vinyl or board any more, either. Textiles is a big growth area, with interior décor for walls, soft furnishings, lampshades and a profusion of hard surfaces vying for attention with garment and soft signage applications, while ever more head-turning vehicle wraps remain a perennial favourite.

The writing on the wall

Most wide-format printers can produce wallpaper of one kind or another but they can’t also provide embossing effects that are as variable as the images that are printed. The exception is Dimense from Lithuanian company Veika, which uses a reactive ink that foams when heated to 200°C to create fully variable embossed effects on 1mm thick PVC-free wallpaper.

The Dimense printer is based on a 2.2m roll-fed chassis with two Epson DX7 heads, offers 720dpi resolution in both the CMYK Latex and the emboss inks and produces up to 20sqm/hr at a cost of around €3.50 per square metre. It’s priced at around €70,000 and Veika sees it appealing to printers who want to differentiate their services and also as a prototyping tool for conventional manufacture. More ink types, including metallic, and a significantly faster version are also in development.

Epson’s stand featured printed fashion fabrics by designer Richard Quinn

Printing on more standard substrates, Epson showcased its established SureColor eco-solvent, dye-sublimation and direct-to-garment printer ranges. Particularly eye-catching on the stand were digitally-printed fashion fabrics and soft furnishings, created in collaboration with designer Richard Quinn, winner of the H&M Design Award 2017.

A 3D printer with fully variable profiled colour and a clear “ink” to allow back-lit elements and effects was shown by Mimaki. The 3DUJ-P deposits acrylic resin to manufacture finely detailed coloured objects – unsupported elements as thin as 1mm2 in cross-section are possible – occupying volumes up to 500 x 500 x 300mm. The company suggested applications ranging from (small) signage to fashion items, figurines and architectural modelling. The 3D printer is expected to be available later in the year at a cost of under €200,000.

Mimaki also introduced a new entry-level dye-sub thermal transfer textile printer. Designed for ease of use, the 1.3m TS30-1300 is capable of producing just under 20sqm/hr on polyester-based fabrics.

EFI had a new textile printer to show as the result of its Reggiani acquisition, the Renoir Flexi, which it described as “the Vutek of industrial textile print”. The 1.8m printer uses Dynaplast technology (a sticky belt, in other words) to handle a wide variety of fabric types from knitted to woven, including stretch fabrics, at speeds of over 400sqm/hr.

One of the few gaps in EFI’s LED-curing UV hybrid roll/flatbed range was plugged with the addition of the Pro 16h, which sits above the 1625 model, offering up to 40% greater performance at up to 90sqm/hr with 1200dpi resolution, driven by an embedded “hard wired” Fiery controller.

Getting heavy

Durst also weighed in – literally, since the machine can take 600kg jumbo rolls holding 15,000 sqm of fabric – at the high productivity end of textile printing with the 390sqm/hr Rhotex 325 which uses the company’s water technology for environmentally friendly printing. The same technology is used in the flatbed Rho WT 250 which can print on pre-primed polymers and plastics at up to 80sqm/hr as well as paper and board, where it can hit 190sqm/hr.

Tweaks to the speed and resolution of the Rho 512R Plus bring the numbers to 400sqm/hr and 1200dpi respectively, while the Rho P10 250 Plus gets its speed upped by 40%, an ink saving mode that cuts consumption by up to 15%, an option for double-sided printing and the ability to add “haptic” texture effects to prints. Durst also showed a multi-camera image capture system for fashion applications and an augmented reality application for remote support.

Soft signage was also the focus of the Agfa Avinci DX3200, which made its European debut in Hamburg. The 3.2m dye sub printer works with polyester-based materials and can print at up to 540 x 1440dpi. An LED version of the Jeti Tauro 2.5m hybrid roll/flatbed was also shown. These, and all Agfa’s other wide-format printers in both the Jeti and Anapurna ranges, are driven by the Asanti workflow.

Another adopter of LED curing was swissQprint, which has added it to its Nyala and Impala flatbed hybrids, in addition to making a number of mechanical enhancements. The “4×4” option gives nine channels, allowing the printers to run double CMYK configurations for improved throughput and still support white ink or varnish as well. The Nyala 2 was the recipient of an EDP (European Digital Press) award, as was the Swiss company’s Rob loading and unloading robot.

HP’s stand included a shopfront to demonstrate applications for its new Latex print-and-cut machines

HP marked its arrival in the print-and-cut sector with the introduction of the 300 Latex series which includes 54- (Latex 315) and 64-inch (Latex 335) models for applications like floor and windows graphics and stickers. They are supported by the HP Signage Suite software (SAi’s Flexi cloud-based package). New textiles for use in soft signage printing with Latex devices were also introduced, plus a new flexible substrate loader for signage applications on the Scitex 17000 press. HP’s PrintOS suite of web and mobile applications for job creation, tracking and print fleet management has been extended to support HP’s Latex and Scitex printers as well as its Indigo family.

SAi’s MyFlexi allows quotes to be generated on the move and updated automatically to the office

When it all gels

Canon provided the first mainland European showing of the Océ Colorado 1640 (it was shown at Sign & Digital in the UK and reported in depth in Digital Printer’s April issue). Canon Europe’s Mark Lawn said that white ink would be added soon and that the Colorado was the first of a family of UVgel products for which Canon anticipates customers will find novel and unforeseen applications. By the start of Fespa, 30 pre-orders had been taken in the EMEA region; the unit is expected to ship in late June.

Another new technology platform that was being rolled out to see what printers make of it was the new B1 product from Inca, who call it the Onset M, which is also being offered by Fujifilm, who haven’t named it yet. The device uses a full-width imaging array, UV-cured inks and is said to match litho quality, though it is also able to print on a variety of non-paper media up to 10mm thick.

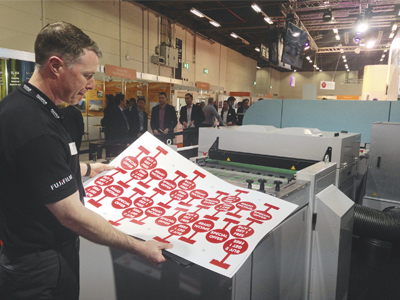

Steve Wood, marketing manager at Fujifilm shows an example of the kind of work that the new B1 printer can produce

Although productivity tops out at 200 sheets per hour, Inca CEO John Mills sees it as being a good fit for B1 printers whose litho press productivity is reduced by having to run short-run jobs.

‘Lots of short-run get bundled in with offset work, so this takes the load off litho. It also cuts out laminating for mounting to substrates, and saves waste of expensive substrates getting to colour,’ he said, suggesting that it would also fit well in sites with multiple smaller flatbed printers or where short-run work on plastics and other difficult substrates is required.

Fujifilm has a less prescriptive sales strategy, looking to see where the market interest is and allow customers to drive applications. Marketing manager Steve Wood commented, ‘The sheet size works with existing equipment for print and cutting; screen printers see it as a good size and it also suits non-graphics applications such as metal for packaging, or credit cards.’ Other applications could be led by the ink types available, Mr Wood suggested.

Novel applications are also what very large format 3D printing is about. Israeli company MassivIT was showing examples of objects printed with its 1800 3D printer. The ‘raw’ printed material is a translucent white, which lends itself to backlighting as in the example of a metre tall perfume bottle, but can also be painted or wrapped to provide a range of finishes.