Personalised advent calendars produced by Ultimate Digital

Who better to share their personalised print prowess than the winners and nominees of the relevant categories of the Digital Printer Awards. Michael Walker discovers their secrets.

Variable data printing (VDP) can take many forms. It underpins transactional print and personalised direct mail of any kind, is a key component of multi-channel communication campaigns and is now even finding its way into packaging. What all these applications share is data and some kind of digital printing device, but the way they’re implemented is itself quite variable.

To get gain an insight into a range of VDP applications, we spoke to four companies who won or were nominated for the Variable data and Transactional and direct mail categories in the Digital Printer Awards 2016. Their experience and expertise are invaluable to help you gauge the opportunities and the challenges of offering variable data printing.

The multimedia consultant

After a stint in print management, Ian Sullivan formed what is now Paperhat Consorcio at the end of 2010. The company was initially a print consultancy but evolved rapidly into a specialist multi-media marketing agency. While print is an important part of the multi-channel projects that Sullivan is involved with today, his VDP roots go back the 1990s when he was at direct mail house SR Communications.

‘We saw VDP’s first growth then,’ Mr Sullivan recalls. ‘It was single-colour overprinting on litho. I was challenged to look at four-colour VDP, but we were held up by RIP speeds.’

Although the technology progressed, Mr Sullivan felt that the market for VDP didn’t keep pace. While agencies showed an interest, they wouldn’t release the budget to try it. ‘The DMA said that 1-2% response rate for simple personalised mail was normal and that became the comfort zone. More complex VDP with colour images, names and pie charts was unknown. It took a lot of courage for an agency to commit to full colour VDP when they didn’t know the ROI,’ he recalls.

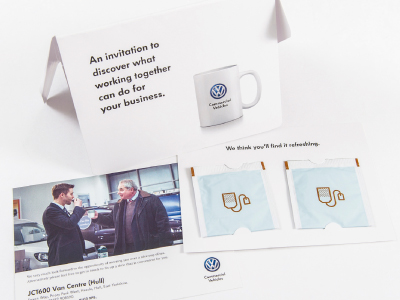

Paperhat’s job for Volkswagen, which was nominated for the Digital Printer Awards 2016 Transactional and direct mail category

Even now that response in the 20-25% range has been demonstrated – and Mr Sullivan was involved in an innovative campaign for BT that involved printing personalised call plan data onto acetate, which netted a 40%+ response – he feels that the markets still don’t ‘get it’: ‘Brands are beginning to wise up, I hope, but now there is mobile, augmented reality and social media on top of all the other channels. No one has confidence.’

The biggest challenge for the printer is data, though. ‘It’s all about the quality of the data,’ says Sullivan. But even with the trackability of digital channels, ‘tastes change all the time; interaction with the brand changes. It’s impossible to keep up, probably 20% [of the data] will be out of date on the next round.’

Getting documents designed for variable data is also key. Paperhat Consorcio’s solution was putting designers together with the data specialists so that they could learn from each other.

The high volume web-fed DM house

Dartford-based mailing house Howard Hunt has web presses that routinely churn out runs of 4,000,000. These are complemented by a variety of inkjet and toner units from Kodak, Xerox and Xeikon, which produce runs from 10 to 1,000,000 personalised pieces.

However, the digital side isn’t knocking out personalised photos with names written in the sand or clouds, according to director of technology Stuart King. ‘That made an impact eight years ago but we don’t get a call for it now. Our projects are complex, template-driven applications that use switches and triggers for email and SMS stages. It’s still in mono but with variable tables and image swaps, it’s very highly personalised,’ he explains.

Client demand for reduced campaign lead times has meant that Howard Hunt has undertaken considerable in-house software development in order to integrate and automate its processes. This supports detailed audit trails for integrity checking and enables shopfloor staff to make on-the-fly decisions about where to route jobs to make best use of offset and digital press capacity.

Like Mr Sullivan, Mr King thinks that the right skills are key to running efficient VDP operations, but extends the necessary skill set beyond data and graphic design right across the business, from sales and client services right through to packing and delivery.

GMC document composition software is used, and although Mr King investigated PDF/VT three years back, Howard Hunt has stuck so far with GMC’s own output format, which includes the necessary metadata for job tracking, to drive the digital overprinting units, and a conventional static PDF workflow for the offset printed shells. If the company moves to a ‘white paper’ factory model, that approach might change, however:

‘We’re moving into transactional, but from a direct mail background,’ comments Mr King. His current analysis shows that the large web presses are still cost-efficient, but he is keeping a close eye on developments in production inkjet. ‘There have been significant leaps in quality on standard stocks, reducing the litho-inkjet gap, which has driven the appetite for review.’

The sheet-fed digital DM printer

ProCo started personalisation with mono overprint on litho-printed shells, but over the last 10 years has invested heavily in HP Indigo presses. The acquisition a year ago of a B2 Indigo 10000 has tipped the balance across the company’s Sheffield and Stansted sites in favour of digital print.

ProCo’s job for Activity Superstore was nominated in the Digital Printer Awards 2016 Variable data category

‘The Indigo is the Rolls-Royce, and that does make for more costly pages, even though we can do two-colour work via the spot colour facility,’ says solutions consultant Andy Lydiatt. ‘The lower quality digital machines are getting good enough for “business quality” so we’re focusing on high quality, high coverage more “boutique” campaigns which lend themselves to multi-channel.’

ProCo has GMC PrintNet and EFI DirectSmile software. It has integrated the latter with its own bespoke software via the DirectSmile API to handle trigger events in multi-channel campaigns. ‘One tool doesn’t fit all, and we want to keep cost per page down,’ says Mr Lydiatt. The company has in-house software development capability, and ‘went through a period of almost becoming a software developer, but clients deal with us because we print.’

VDP projects fall into two camps – everyday one-off mailing execution with simple timetables and mailing data, and event-driven projects that take longer to plan and implement but which yield more benefit to the client and more volume for the printer. ‘The trick is to get responses back and complete the circle; it needs everyone round the table, openly collaborating,’ explains Mr Lydiatt.

Looking for new VDP business involves pitching ideas to new prospects but ProCo’s experience so far has been that the best and most interesting projects originate with existing clients, where ‘we’ve earned the right to have those conversations,’ as Lydiatt puts it.

The flexible packaging converter

Ultimate Digital is the digital arm of Grimsby-based flexible packaging converter Ultimate Packaging. Established in 2010, Ultimate Digital uses two HP Indigos to produce very short run test marketing and variable content packaging for retail brands. The company can print on a wide range of common flexible packaging substrates.

Although even at 20 linear m/min, the faster Indigo’s productivity is a far cry from what flexo presses routinely manage, the value of the digitally printed packaging means that it’s quite a different proposition as far as clients are concerned.

‘We’re interested in doing things with lots of value,’ explains executive director Chris Tonge. ‘Cost gets wiped away because we can do such different things.’

One example was Waitrose’s 2015 Christmas campaign in which customers who had ordered turkey breast parcels for collection at any of 240 stores were presented with free personalised cool bags when they came to collect. Ultimate Digital also produced personalised sleeves and bottle bags that were given to customers who engaged with the accompanying social media campaign on Instagram, Twitter and Facebook.

This year, the company is combining its Smartflow in-house developed web-to-print and production workflow which Mr Tonge describes as ‘Moonpig for packaging’ to enable consumers to order personalised advent calendars from confectionery manufacturer Kinnerton. Seven different designs are on offer, based on popular children’s characters.

Ultimate Digital’s plans don’t stop there, either. The company is aiming at one-to-one communication with consumers via links from packaging to online ‘experiences’ from which data can be gathered to drive loyalty schemes. To be launched next year, the plan is to unveil to consumers a ‘giant digital workflow’ that will connect the virtual and augmented reality worlds to packaging. ‘This will move personalisation forward, so packaging is just part of the overall experience. We’re aiming at TV advertising-size budgets,’ says Mr Tonge.

The bottom line

Whether the message winds up in a mailer, on a postcard, in a letter, catalogue or brochure or on a packet of crisps, the crucial component that adds the value is the data. It could be better-targeted direct mail; it could be part of a multi-channel campaign with links to the digital world, or it might be a whole new dimension in packaging, but variable data is potentially one of the best ways to boost your own ROI from your digital press.

Read the full issue online here