*Advertorial* Print is changing, run lengths are decreasing and there is less money to be made from printing long runs. Shorter make ready times on litho presses have addressed this up to a point but this is still a time consuming and wasteful process; while printing digitally has meant a compromise in quality.

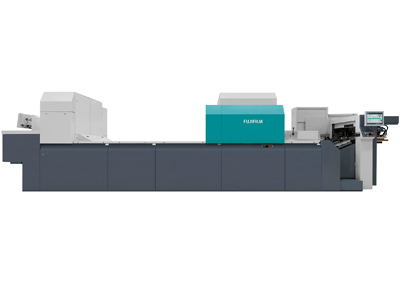

The previously unattainable dream of outstanding quality with no make ready is realised in the Fujifilm Jet Press 720S, which is now in production with over 70 customers worldwide including the UK.

Efficiency is achieved by reducing the make ready time and waste to zero. The time between each printed sheet is 1.3 seconds, which with instant changeover means that the time between jobs is also 1.3 seconds.

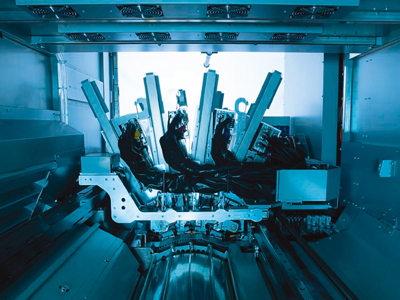

A combination of technologies enable the high quality achieved on the Jet Press 720S including the Fujifilm Dimatix Samba printhead, Vividia water based ink and Rapid Coagulation Primer, which allow the use of standard litho stock, both coated and uncoated as well as canvas and plastic.

Specification

Imaging technology: water based inkjet

Printhead: Fujifilm Dimatix Samba

Ink: Vividia CMYK

Primer: Rapid Coagulation Primer

Speed: 2700 sph

Resolution: 1200 x 1200 nozzles per inch with

four level greyscale

Maximum paper size: 720 x 532 mm

Stock range: 127-350 gsm (0.2 – 0.6 mm when

configured for heavier stocks)

Media types: Coated matt and silk paper,

uncoated paper, canvas and plastics.

Workflow: XMF 5.5 or later or integration with third-party systems via XMF Processor.

‘It is without doubt the leader in the inkjet field, allowing us to print down to a two picolitre drop with wide colour gamut, giving huge vibrancy and control of the ink on the sheet,’ said Fujifilm Jet Press solutions manager Steve Freeman. ‘We were happy to show the quality by printing live at drupa, and were happy to give away the samples that were printed and finished on our stand.’

While the machine proved itself at drupa, it can also be used to proof itself.

‘Why emulate the final printed result on a plotter when you can guarantee the result by printing the proof on the Jet Press?’ asked Mr Freeman.

The Jet Press 720S can run full variable data at 2700 sheets per hour.

Zero make ready is coupled with industry leading uptime and reliability, which means nearly zero downtime. That ensures that customers can rely on its 2700 sheets per hour throughput as an achievable figure day in day out rather than an occasional sprint performance. Because it is a contactless printing system the quality stays the same, day to day week to week, there is no need to recalibrate to take account of aging blankets or other imaging consumables.

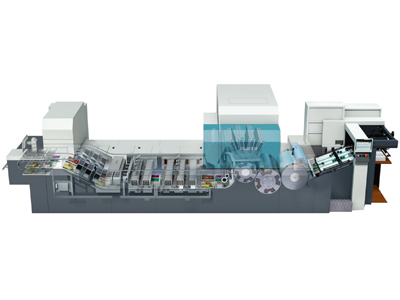

Printing section

Work flows off the press as quickly as it flows onto it; sheets drops into the delivery dry regardless of the paper. This means second side printing or finishing can be carried out straight away.

‘There would be no point in reducing the make ready and increasing the uptime if we couldn’t get the job into the bindery and out of the factory door quickly,’ added Mr Freeman.

Weighing fourteen tons, with a litho feeder and delivery, and using grippers and cylinders it is undeniably a press.

‘Printers get it, they understand the sheet transport and with front lays and a side lay that sheet to sheet and back up registration will be as good as they get on litho, they understand the IR and hot air drying,’ said Mr Freeman.

Barcode section

However it is more than just a litho substitute, the advanced inkjet system and a barcode reader enables full variable data production with integrity at full 2700 sheets per hour both single- and double-sided. That combination of the best of litho and digital opens up new opportunities according to Fujfilm Graphic Systems UK director Keith Dalton: ‘There is a wealth of creativity to tap into as an industry, print is no longer huge run lengths on paper only but there are now much wider applications to be fulfilled. drupa has shown that our industry is anything but in trouble and there is an opportunity here for any company with a creative mindset.’

• The Highest Quality Print Available

• No Make Ready

• No Waste

• 1.3 Seconds between jobs

• Higher colour gamut than offset when

Fujifilm Max Gamut Printing is enabled

• Incredible reliability and uptime

• Sheets are dry in the delivery, allow

turning or finishing immediately

Contact details

tel: 01234 572340

email: marketing.fgs@fuji.co.uk

This article is an advertorial; the featured company created the wording and paid for its placement. It has been thoroughly checked by Whitmar Publications to ensure that the information is accurate and meets our standards.