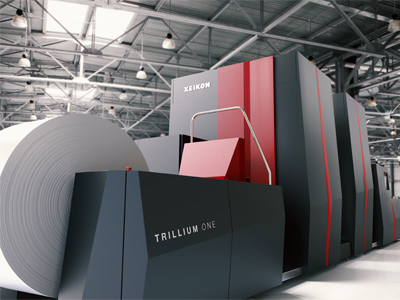

The Xeikon Trillium One

Xeikon will support its ‘Direct. Dedicated. Digital.’ drupa 2016 theme with the unveiling of its brand new portfolio addition – Trillium One.

The four-colour Trillium One press is based on Trillium, Xeikon’s breakthrough liquid toner printing process that was first presented at drupa 2012.

The result of a joint collaboration between Xeikon and Miyakoshi, Trillium One combines the expertise of two market-leading players, leveraging Miyakoshi’s strengths in the mechanics of a printing press and Xeikon’s pioneering approach to digital imaging, high-speed electronics, high resolution LED technology, workflow and toner technology.

Wim Maes, CEO at Xeikon, the digital printing solutions division of Flint Group, commented, ‘Working together with an experienced partner like Miyakoshi has allowed both parties to focus on their respective strengths. Over the past four years, Xeikon has also worked closely with hand-picked customers to complete the development. This collaborative approach has resulted in a solution that delivers outstanding quality.’

Capable of running at 60 meters (200 feet) per minute at 1200 dpi, with a print width of 500 mm (19.7 inches), Trillium One combines cost-effectiveness, high quality and speed in a unique printing press poised to change the digital printing landscape. Shipping will begin in Q2 2017. Direct marketing materials and catalogues have been identified as the primary target applications for Trillium One, with more target markets and applications to be added over time.

High throughput and substrate flexibility

In addition to speed and quality, the Trillium One difference includes increased throughput from prepress through production and finishing (which includes drying time), especially since Trillium’s liquid toner requires no drying. Recycling of unused toner and carrier fluid within the press contributes further to cost reduction, and there are no inkjet heads to maintain or replace. The Trillium front end drives the press at rated engine speeds, regardless of the complexity of the job. And Trillium One can print on a wider array of substrates than dry toner or inkjet presses.

Trillium technology has several environmental benefits as well when compared to other printing technologies. It emits no VOCs, does not need venting, and uses no solvents or other noxious chemicals. Its LED imaging process uses less energy than laser imaging and the press produces less waste compared to offset, with no need for makeready sheets and no inventory obsolescence since materials can be cost-effectively printed on demand.

Taking it to another level

‘With Trillium One, we have been able to hit a new technological level in terms of speed and cost for variable digital print,’ Mr Maes stated. ‘We are excited to present such a huge milestone in Xeikon’s history at what we think will be a historic drupa. Trillium One adds a new dimension to the world of digital printing that has not previously existed in the marketplace. It has the ability to take digital printing to an entirely new level in terms of price performance metrics – all factors that make Trillium unique.’

At the heart of this developmental leap forward is Xeikon’s proprietary Tonnik liquid toner. It combines all the advantages of dry toner in liquid form. It is extremely economical and environmentally friendly thanks to its high deinkability rating.

Mr Maes said, ‘Trillium One with Tonnik enables print service providers to meet ever-increasing quality and productivity standards. It is the culmination of Xeikon’s three pillars of expertise. In imaging, we are continuously improving speed and print quality. In toners, we have been working on our own developments to increase our portfolio to meet customer demands. In workflow, we have our own proven DFE, the X-800. Together, these comprise a high quality, robust solution that will help our customers acquire new business and cement existing customer relationships.’

Mind the microgap

An additional benefit is Trillium’s Microgapping process. The initial 5 micron gap between rollers means that toner particles easily transfer from one roller to the other with extreme precision and at a very high speed as the substrate progresses through the imaging process. This improves registration and image quality and creates increased density stability. ‘So we’re not only printing at 1200 dpi, but we can also guarantee a very accurate dot placement,’ Mr Maes added. ‘Trillium is, just like offset, a full contact printing process.’

He concluded ‘Trillium One combines the strengths of offset litho in delivering high print quality, ink densities, and image coverage on different substrates, with the strengths of digital printing which enables variable data printing at higher volumes with lower costs and easy operation, thus creating a powerful production solution unmatched in the marketplace. It will allow printing operations to transform print quality and at the same time open up new markets.’

Up close and personal

At drupa, in Hall 8a, Xeikon, in its first major event since it was acquired by Flint Group, will showcase Trillium One’s production flexibility. Those wishing to take a closer look inside the press can enjoy a Trillium Virtual Reality Experience highlighting numerous innovations. As part of Xeikon’s ‘Direct. Dedicated. Digital.’ Theme, 30 minute demonstrations, five times a day, will highlight a wide range of applications.

Xeikon will also show the CX3, which has seen more than 20 systems installed since its September 2015 launch; the five-color Xeikon 3500 flagship of the Xeikon 3000 series; the new Folding Die-Cut Unit; the Xeikon 9800; and cloud-based XeikonColorControl that lets printers ensure repeatable, predictable colors and the best simulation of custom spot colors. Taggant marked spot color toner for anti-counterfeiting and brand protection will also be featured.

Throughout the show, Xeikon experts will be on hand to gain an understanding of the business needs of visitors and to share advice on quality, productivity and technology; and Xeikon will also be promoting the power of its long-established Aura partner program.

Just the Tonnik

At the heart of the Trillium technology is Xeikon’s proprietary Tonnik liquid toner. It combines all the advantages of dry toner in liquid form. It is extremely economical and environmentally friendly thanks to its high deinkability rating.

With Tonnik, Xeikon has created a high viscosity liquid toner with particle sizes of less than 2 microns that deliver an outstanding level of quality in high resolution made possible by the small particle size and Trillium’s the imaging heads (1200 dpi). The toner contains no evaporating carriers, resulting in more environmentally conscious print production process that also mechanically recycles the majority of the carrier liquid during the printing process. Carrier liquids derived from biomaterial further increase the sustainability of this new technology. And INGEDE has certified that printed materials are deinkable.