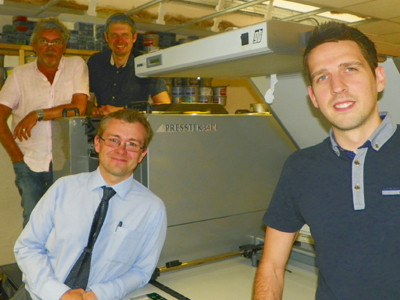

The Diguru management team: top – Richard Harwood (left) and Alex Marszal; bottom – Nick Newby (left) and Luke Willett

Down near the south coast in Eastleigh is a company making great strides by mixing digital print capability with two Direct Imaging presses that image plates on-press. Andy Knaggs visited Diguru.

Setting up as a business in the teeth of the recession, the people behind Hampshire company Diguru had choices to make. Managing director Richard Harwood and operations director Alex Marszal had broken away from another local printing firm which had been a purely digital operation, and they did not have much experience with litho printing. They did have ideas and passion however, and they saw a possibility to offer more than digital and wide format services in their new concern.

The answer proved to be a technology that many companies seem to overlook these days: Diguru bought a DI (Direct Imaging) press from Presstek. That was five years ago now, and the company now has two Presstek 34DI machines, so it is fair to assume that the technology has stood up and delivered.

Alex Marszal explained: ‘Our main aim was to offer our clients a cost effective solution when larger run lengths are required. The Presstek DI being water-less, using soya-based inks and having a small footprint has environmental credentials that would help get us into the councils and the education sector alike. Five years ago, the investment in DI was a risky one because we had a digital background, but clients were buying that run length between 750 and 1000 SRA3 where you start to crossover into litho. For digital, the click rate was just not effective, and for a B2 litho printer it was too small a run, hence the investment in DI, which sits in that crossover point between digital and litho, and with the size of the plates it becomes a very cost effective way of printing.’

With many jobs that have a run length geared towards digital print, Diguru will now also offer the customer a bigger run from the DI press for a similar price. ‘It works really well. The quality is obviously pin-sharp, and it is water-less so the dot gain is minimal. Clients are also using the press for when wet proofs are required for other sectors of print for which they outsource,’ he said.

Working with a 34 cm format DI press which images the plates on the press, Diguru has been able to be competitive with B2 printers. ‘Typically anything up to 10,000 A5 leaflets and A4 letterheads are ideally suited run lengths. Because of our sheet size, if it’s a 20-page A4, 20,000 copies, we can advise the client that a B2 printer will be more cost effective. It’s down to the finished size of the job. At the same time, we have produced 5000 to 10,000 16-page A5s. We can run the presses side by side and run them cost effectively.

The second DI press was installed in July, and an experienced Presstek minder was recruited. The decision to invest was taken due to the first 34 DI being over-loaded. It is not the only investment that Diguru has made this year, as it also took delivery of a Heidelberg Linoprint CV in March. This is the five-station model with white and clear toner, which Ricoh calls the Pro C7100. It also has an extended banner printing capability, enabling Diguru to keep 6-page A4 work in house. The white and clear toner make printing on different clear and coloured stocks and simulating a spot UV laminate possible.

Of the Linoprint, Mr Marszal said: ‘The creativity is just endless. The white and clear toner and banner sheet open up possibilities to agencies that they did not know existed.’

The company is still growing after five years, and investing in cutting edge technology to meet client demands and provide new options. Alex Marszal says it is ‘very much a team effort here at Diguru; we’ve got excellent staff in all areas of the business’. Queries at any stage of production are taken up with customers on the phone. ‘It’s a five minute conversation and the client appreciates that. Other printers might just print it and say “there’s your job”,’ he said.

In closing, Mr Marszal paid tribute to the impact of the Presstek DIs on the business’s success. ‘Without them I don’t think we would be in the position we are today. The DI press has made us stand out from the crowd and works very well in conjunction with the large format and digital side of the business. It has given us another aspect for growth. It has worked out really well for us.’