New fully automated system with stitching, folding and trimming

The print industry is increasingly faced with shorter run lengths, so customers are looking for fully automated, all-in-one systems that work at the touch of a button. They want a tool-less system with no human intervention to handle any application.

In an increasingly digital world, most printers understand that it is in the bindery where real value is being added to the printed product. All printers want the same: easy integration, automation, precision and minimal wastage.

So when people work in minutes and hours, not days, customers want help in terms of providing highly automated and effective systems. Notwithstanding quality, reliability and consistency, what is important is providing tool-less equipment with full automation and variable data that is simple to use.

In years gone by it might have taken anything up to an hour to get booklet-making systems set up in a correct format. That might have been acceptable for a 50,000 run, but these days they can be less than 20, so printers need a makeready time of just seconds.

Duplo was the world’s first company to introduce dynamic bookletmaking. It is a company that has remained at the forefront of technology and works closer with its growing number of partners and customers than ever before. However, good products do not work without huge R&D investment – up to 7% of turnover is reinvested annually – and a talented group of people who work for Duplo, many of whom have been with the company for more than 20 years.

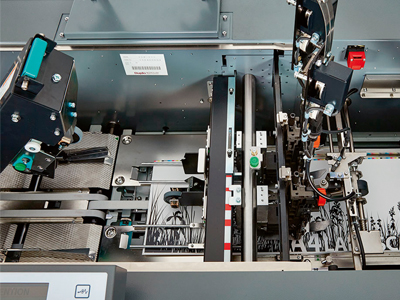

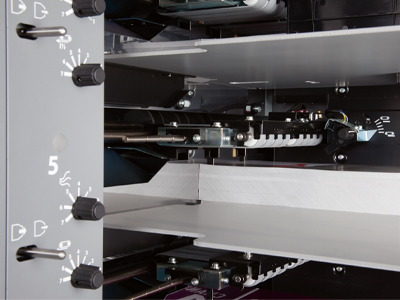

Clear paper path and easy access

In terms of new developments, Duplo reinforced its top slot in booklet making and saddle stitching with the launch of a new flagship model, the 600i BookletSystem, in August 2015.

High-volume digital and litho production are key markets for the new system, with commercial printers, education, public and private sector and processing industries being actively targeted.

The Duplo 600i Booklet System replaces the highly successful 500i Booklet System, which was introduced 12 years ago and has sold more than 2300 units in Europe, the Middle East and Africa.

The powerful, intuitive 600i Booklet System is a fully automated stitching, folding and trimming solution using ultra sonic technology combining the high speed intelligent DSC-10/60i Collator Towers and the easy-to-use DBM-600 bookletmaker and trimmer. It has at least 25 configurations that can combine suction, collators, sheet feeders, slit, cut, crease, squarefold and three-knife trimming operations.

Major benefits of the system include:

Industry-exclusive features such as A4 landscape format Easy set-up and full automated precision, user friendly with minimal operator intervention required Clear paper path so full control of the production process Optimised PC controller that enables operators to create and save an unlimited number of jobs for future instant recall Production speeds of up to 5200 booklets per hour. Adding the optional DKT-200 2-knife trimmer increases this to up to 9000 booklets per hour This knife trimming allows the user to take printed SRA3 or B3 sheets directly from the press and finish the booklet in one operation Tool-less operations and job changeover times of less than a minute High versatility and modular set-up that can be re-configured and expanded as demands change

One of the world’s first users of the Duplo 600i Booklet System is trade finisher Peterborough Print Solutions, a long-standing customer of Duplo. ‘The Duplo 600i Booklet System has been a revelation,’ said managing director Peter Melkowski. ‘As a trade print finisher it has added important efficiencies to our workflows and its functionality appeals to my customer base, particularly those who require A4 landscape work on a regular basis.

Accurate and reliable A.M.S+ suction feed system

‘As an example, in the past it would have taken around four man hours to do a thousand 16-page A4 landscape booklets. But now this is a fully automated process, easily taking under an hour. The advantage that gives us is incredible – there’s definitely a market for this system.’

Peter Jolly, Duplo UK managing director, said: ‘The Duplo 600i Booklet System represents our vision of automated precision. It’s clear from feedback already received that industry professionals will welcome a revolutionary system that combines the robust lines of a large stitching system with exceptional intelligence, productivity and exclusive features such as A4 landscape format.’

He added: ‘We already have the widest range of booklet makers and saddle stitchers in the industry and the 600i Booklet System is another example of how Duplo unequivocally continues to make major advances in the print finishing industry.’