Swiss manufacturer Swigraph has been producing loose-leaf binding systems for decades, and has a range of machines that caters to market needs.

Despite the scenery, the chocolate, the lowest crime rate of industrialised nations, and being the best place in the world to be born according to the Economist Intelligence Unit’s 2013 Quality of Life Index, being Swiss does have its drawbacks.

One of these, says Hratch Boyadjian, is that nothing gets built cheaply. Mr Boyadjian, managing director of punching and wire- and PVC-coil binding systems manufacturer Swigraph, explained: ‘Our machines are very well built. That’s part of the trouble in Switzerland: the price is rather high. We don’t have second-hand machines available. When we get one it goes to Africa and works for another 20 years there. We cannot make cheap machines – we have this pride in places like Switzerland. There’s skill, fine mechanics, precision, many intricate parts.’

This is a long-established company, which exports its technology worldwide, and has a small client base in the UK. It considers itself a specialist in loose-leaf binding, and has medium range products that can handle spiral binding with metal, double-loop ‘wiro’ binding, and plastic coil binding, as well as punching machines, calendar hangers and tab reinforcing and cutting machines.

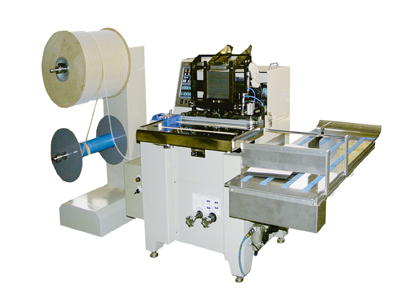

Mr Boyadjian’s point about the quality of the machine build is backed up by Nigel Clarke, director at Waveprint in Birmingham, which binds products such as homework diaries and yearbooks for schools. It wanted a metal spiral binding system in 2012 and Swigraph was recommended to it. It took just a couple of months for a deal to be worked out for one of Swigraph’s R6 automatic spiral binders, which can reach an output speed of 550 pieces per hour (A5 booklets) with a single operator.

Mr Clarke told Digital Printer: ‘The engineering behind the Swigraph is a lot more comprehensive than other systems we looked at. It’s very well engineered and thought-out. The wire feeds more efficiently, it’s a bit quicker, and we also took the offline end-loop crimping, which locks the wire around itself so the children can’t dismantle their homework planners. The only other way to do it is by hand and that would be very difficult. The crimping was a big deal for us. A lot of customers insisted on that and the way the Swigraph technology works is a lot more efficient, a lot more reliable and solid.’

Swigraph’s simple, pneumatic crimper unit functions on both 2:1 and 3:1 pitches. These days certain components are made elsewhere in the world, including the Far East, and the Czech Republic for die-casting, but 70% is still manufactured in Switzerland and the machines are assembled there. R&D also takes place in Switzerland, and the company has a number of patents on its machines, demonstrating its ability to innovate. The patents include Hooky, an incorporated calendar hanger made of the double-loop wire binding itself, and Snappy, a unique counting and cutting machine. Swigraph distinguishes its technology from the rest of the market by designing systems that apply the spiral bind while the printed booklet is hanging on needles, which is also when registration is made. ‘That’s very important because the spiral or coil has to go through the holes, otherwise the wire will miss the holes and stop. Hanging is the best solution for that,’ he said.

Across Europe, there are variations in the popularity of the different types of binding, all of which Swigraph is able to cater for. Mr Boyadjian reported that while double-loop binding is much used in Europe, spiral binding still dominates in countries such as Spain, France and Italy because it is cheaper. The UK market is very much geared towards double-loop binding, with about 10% in plastic coil, he said.

Swigraph is represented in the UK by several resellers, including PrintersMart, Stanley and Don Valley, although Waveprint purchased its R6 automatic spiral binder directly from the Swiss manufacturer. Nigel Clarke found the experience a positive one and continues to do so. He said: ‘They are obviously quite small in that we generally speak directly to Hratch. It’s nice that we don’t have to go through person after person to get an answer to a query. Doing the deal was a pleasure. They delivered the machine working, and they have always been able to resolve any issues we had very quickly.’