An optional feeder head gives the Amiga 52 a top speed of 25 metres per minute

Digital Printer’s Finishing Special continues with a series detailing the latest product developments across different post-press technology areas.

Vivid Laminating

The company launched new Matrix systems at Ipex – upgraded systems with pneumatic rollers that allow much faster production speeds and make it possible to use standard OPP film with digital print, and with duplex capability.

Another thing the firm has been working on is Flatbook. This is essentially an add-on for the Matrix system that solves the problem of book cover curl up when using a conventional OPP laminating film. Using a nylon film rather than OPP is quite a bit more expensive. Flatbook involves a new cutting device which bolts onto the top of Matrix and cuts out a channel of the film as it laminates covers, leaving an un-laminated inside spine. When PUR or hot melt glue is applied during binding, the glue sits in the spine but not on top of the lamination. The result is a totally flat book that does not curl up.

D&K

Ipex saw a successful launch of the new double-sided Europa PB, which is based on the earlier, single-sided Europa, which now has over 200 installations.

Equally adept at processing both litho and digitally produced print, D&K said the unique configuration of the Europa PB was conceived for photobook producers who need to obtain an identical finish on each side of the sheet. Each of the two identical laminating heads comprises a chrome laminating roller and rubber nip roller individually controlled for heat and pressure. No reduction in speed is necessary when laminating both sides at the same time, while one of the laminating stations may be turned off when laminating one side only.

IFS

IFS unveiled the Foliant Vega 400A at Ipex, a B3 laminator with a non-stick lamination pressure roller that allows window lamination, as well as thermal lamination. It replaces the Gemini C400A. Running at 18 metres per minute (up from 15), the system is ideal for digital or litho short to medium run lengths, with a suction belt feed from the top of the stack. Other capabilities include an intuitive colour touch screen control for easy set up and fast make readies and low level housekeeping as there is no need for regular cleaning. The Foliant Vega 400A is priced at just under £20,000.

Foliant has also enhanced the production capability of its Mercury 400SF and Mercury 530SF systems to run at a faster 25 metres per minute. The manufacturer’s highest specification Mercury 530 was demonstrated at Ipex with double-sided lamination and film air shaft to speed up the changeover of film.

Friedheim International

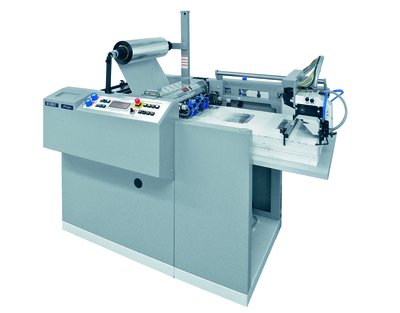

The Komfi Amiga laminators (which come in 36, 52 and 76 cm versions) have been given a bit of an upgrade and are now a little more productive. The Amiga 52 for example can process at up to 25 metres per minute with an optional feeding head (15 metres per minute otherwise). This feeder head additionally enables processing of paper weights up to 600 gsm, instead of 350 gsm. The laminator is specifically designed for digital printing, with a bottom suction feeder, automatic and electronically adjustable sheet overlap control, and NBR (rubber) counter pressure roller.

Apart from the Komfi feeder head, options include a film slitter, a Teflon-coated non-stick counter pressure roller, and a machine modification for embossing.

Watkiss Automation

The Bedfordshire company has been getting increasing numbers of enquiries for laminators and believes it has found a range to meet market needs in the Mamo Plasti range from Italy. The range extends from the smallest Plasti 330 up to the wide format Plasti 1100.

The SRA3 format Plasti 350 is targeted very much at the digital print market, with both friction feed and suction feed possible. The 520 mm wide Plasti 520 is manual feed but soon to become automated. With these laminators there is now a wide range of finishes, with the most popular being soft touch. Watkiss said the Mamo Plasti 350ASPwith high pile suction feeder and automatic overlap and separation is perfect for small print shops who need to in-source laminating operations with a small investment, and for commercial printers who need to process low volume digitally printed stock. It costs around £9,000.

The Mamo Plasti 350