Through its Sensory Print division, 1st Byte has taken a coherent message to the market in terms of special effects printing. Digital Printer asked managing director Lawrence Dalton about the market approach.

Some printing companies will happily toil along, sticking to the tried and trusted print and finishing methods, rarely if ever looking beyond the basics that CMYK offers. Others have it in their DNA to seek difference and push boundaries. Though he does not say so specifically, Lawrence Dalton, managing director of 1st Byte, would seem to fit squarely within the second camp.

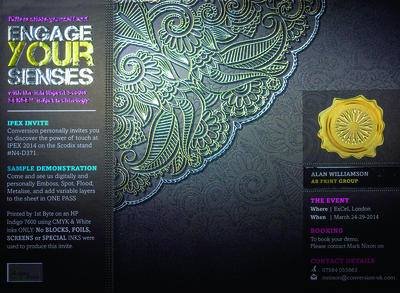

Towards the end of his interview with Digital Printer he says that ‘it has been my ambition for 1st Byte to be seen as a company to go to when you want something different’. A good way to achieve that has been through the company’s most recent press investments – in 2012, the UK’s first HP Indigo 7600, which can print white and clear ink onto black and heavy substrates, and then one of its first Scodix digital enhancement systems, which was installed in January 2014. 1st Byte has got the bit between its teeth now and the company has gone so far as to launch a new division for creative print applications called Sensory Print, backed up by an internal creative services department.

It all makes Mr Dalton a good man to sound out about how to sell this kind of added value print, since communicating the capability is every bit as important as gaining it in the first place.

‘It was something that we had to build the demand for,’ he told Digital Printer. ‘We had the creative services department which started the year before, and that helped us in talking to clients and designers. We would often say: have you seen this? We would do a test for them and mostly they would say it was great. People have always been able to do spot UV, but if you want to do five or 50 books, the cost becomes very onerous. Suddenly with digital and the special effects that we have here, customers can use special effects without any real price and time constraints. That’s what these special effects in digital bring to the game.’

The message has been delivered to the market via a succession of educational seminars for customers and designers, which 1st Byte has partnered with Fedrigoni on, using the paper company’s Clerkenwell offices, which is just along the road from 1st Byte, as a venue. The seminars take place roughly every two months and have been a tremendous success, said Mr Dalton, each attracting 30 to 40 people, as many of them being non-clients as existing clients.

He said: ‘The seminars have been a great benefit to us. We have got them down to a two-hour slot off site, giving talks, showing videos and handing out samples. We are finding that they are now self-perpetuating. In the early days we would send out hundreds of emails, trying to get people here; now the seminars are half full without us promoting it at all.’

He puts a lot of this down to the standard of the 1st Byte website, which it has invested a great deal in, and which is added to with more content more or less every day. Even so, he reveals that he is looking to improve it still further with a new version next year. When 1st Byte does send out printed invitations for such events, they naturally make use of the special effects capabilities of the HP Indigo and Scodix.

He does accept that the ongoing success of the seminars is probably helped by their central London location, and says that if 1st Byte was out of town it would probably have to make the seminars more of an event to attract attendees.

Digital Printer asks about the sales approach: does it help to emphasise the potential returns of added value print, taking the discussion away from price?

‘You can’t avoid the cost aspect,’ he replied. ‘If it’s too far outside their thoughts, there’s no point wasting our time to promote it. We are fairly open about pricing with clients. If they have not used it before, we will do something free of charge. It is about giving them that wow factor.’

Sensory Print has seen 1st Byte win new work that would not otherwise have come its way. It has even attracted some packaging jobs through being able to print with white ink and to create metallic effects using Color-Logic. The problem is that seeking differentiation is a never-ending quest. He joked: ‘What we do next year is the perpetual question…edible print?’