Comprised of the Roby Junior 2 case maker, X-Case casing-in machine and X-Forming Book press and joint forming machine, Zechini’s X Book Line is suitable for both short and medium sized runs.

The Italian case binding equipment manufacturer Zechini has been making high quality technology for more than 60 years, and Friedheim International is now bringing this technology to the UK market.

A wide portfolio of systems exists, with both fully automated and semi-automated machines included. Here, the focus is on semi-automated units that when put together form what the company calls the X Book Line – the Roby Junior 2 case maker, X-Case casing-in machine and X-Forming Book press and joint forming machine – which Friedheim’s Roger Cartwright says will be attractive to both traditional craft book binders and the burgeoning fast turnaround on demand and short run book printing market, populated by many digital printing companies. Even for larger volume producers, the X Book Line can prove useful as a means of producing small volumes of advance copies for a publisher.

Mr Cartwright said of the Zechini equipment: ‘It’s extremely versatile. If you just want a very basic casing-in process you can buy just that unit. Even with the X Book Line there are three levels of complexity and speed depending on the application. They also do a huge range of peripheral equipment around the main process of case making and casing in – free-standing corner cutting units, head and tail banding machinery to put a band around the top of the spine, book presses, joint forming, and case rounders. They are substantially built machines but basically quite simple as well, and very reliable.’

In mechanical terms, the Roby Junior 2 case maker is capable of cycling around 250 books per hour, but this speed is of less importance in the markets that the X Book Line is aimed at, where short runs may demand frequent changes in job format. Changing quickly between jobs is therefore of far greater importance.

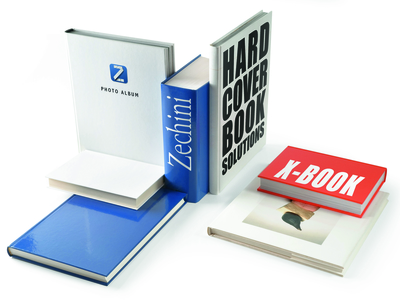

The Zechini X range of casemakers

‘People look at the equipment and think it’s just traditional book binding, whereas the interesting thing is that this equipment is ideal to cope with the explosion of short run or run-of-one books on demand that’s really coming through,’ said Mr Cartwright. ‘It’s semi-automated so it’s very quick to change from one product to the next and produce very small volumes. One thing driving that market is the photobook sector, which is mostly runs of one. We hope we are hitting a sweet spot in the market with that right now.’

There are numerous options with the equipment that can help to increase productivity. The Roby Junior 2, for example, can be specified with a built-in corner cutter, as well as an automated board feeder. A turning-in machine can also be linked to the Roby Junior 2, and it can operate with both hot melt and cold glue.

A complete X Book Line starts from around £70,000 and is a versatile and easy to use step into book casing for companies making moves into the short run book market.