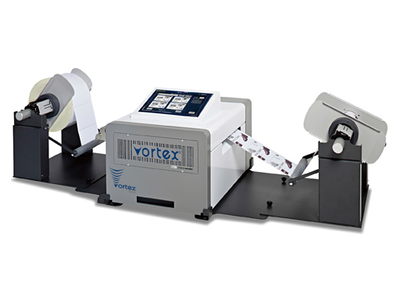

The memjet-powered RTI Vortex 850R is ideal for the label market

With labels being one of the fastest growing sectors of the printing industry, commercial printers can gain entry with super-fast yet affordable technology such as RTI’s Memjet-based Vortex printing systems.

New high-speed, single-pass inkjet systems and high-quality digital inkjet printers have opened doors of enticing opportunity to print service providers seeking to enter and grow within the decal, label, and packaging markets.

To really triumph in these burgeoning segments, print service providers (PSPs) must pursue education and training, match the right equipment with the right applications, gain insight into customer needs and undertake effective selling efforts. Those willing to tackle all these endeavours are likely to find going small can help them to go big.

No one is disputing the size of this opportunity. ‘It’s one of the fastest-growing segments of the printing industry,’ said Peter Barton, director of EMEA business for Reprographic Technology.

‘It is technology driven and it is consumer driven. Everything that is sold has to be packaged. Everything ends up in a package, whether a prescription drug or a packet of biscuits. There are more and more small companies doing food items, and that is a real opportunity. There are also so many different applications for labels, from industrial needs to ‘cottage industries’ and so on. The market is almost infinite.’

Mr Barton urges companies looking to enter the label, decal and packaging end of the business to spend some time educating themselves about the markets and the technology. ‘If I were in their place, I would want to gain that information,’ he said. ‘I would subscribe to trade journals, read the market reports from the analysts and go to all the relevant shows and expos.

‘Label Expo in Brussels last year was an eye-opener for me, and made me realize that packaging and labeling is the only real print sector where the volume is actually increasing – this combined with the low percentage of digital print compared to traditional methods, like flexo, means that this sector has the largest potential for digital growth.’

Print providers also need to decide what segment of the label and decal markets they want to be in. These PSPs should examine their current customer base to see if there is demand for labels within that base.

On the principle that it is ’10 times harder to find a new customer than to keep an existing one’ it is important to explore how much of the ‘wallet share’ is being gained from the existing client base. Are the customers within the existing print client base buying printed labels from elsewhere? Is it possible to add-in this service offering, to keep it in-house?

Getting Started

Some capital investment in digital label printing equipment will likely be necessary, and beyond that is the question of finishing. Will your output need dye cutting? Will it need coating and laminating? PSPs can outsource some of the tasks, but with capital investment can take it in-house and gain greater profit.

New technologies, like Memjet, as used in the Vortex 850R, allow small investments in the range of £5000 to £10,000 to yield massive potential volumes, whereby a 100 metre roll of A4 width label material can be printed in little more than five minutes. This is a big change from the large capital investment that was required by older print technology to achieve the same output.

‘You can ease into the business,’ Mr Barton continued. ‘Find a trade printer and outsource some jobs. You will learn about labels and decals through that partnership, and then you can determine whether you want to bring it in-house. That’s a good approach, and you can make some money with that strategy.’

The RTI team at the Fespa Digital exhibition

As for marketing the printing of labels, decals and packaging, Mr Barton suggested that print providers employ dedicated sales teams, putting salespeople on the street, visiting customers’ locations to understand the way the output will be used. ‘It’s not a situation where you can place a general ad in a magazine, or do a direct mail piece, and get the kind of response you want. You really have to understand what the customer needs. So you must have real people involved, and those real salespeople need to be educated and knowledgeable.’

Speaking of knowledge, PSPs also must comprehend that while many tools exist for the printing of labels and decals, it is essential to match the right technology with each application. Simple software, like Bartender from Seagull Scientific, puts design capabilities in the reach of non-experts; more complex software such as Adobe’s Illustrator can be used for very sophisticated design jobs.

In short, do not jump into these markets without doing your homework.

‘It’s really important to take the time to zone in on what current customers need, the equipment and outsourcing partners you may require to serve them, and then it’s education, education, education,’ Mr Barton advised.

Shorter runs, more data

Of course, the small PSP is going to find it difficult to compete in the high-volume label market. This is a specialist field where, provided there is no need for variable data or versioning, flexo is the de facto standard for production methods. This does require large investments, both in hardware and training/experience. The high cost of time taken for setup of a job makes it impractical to provide short runs, and anything needing variable date such as barcodes, serial numbers, batch numbers etc. will require a second process using some sort of digital printing.

Another factor worth considering is that tonal range reproduction, ink to ink registration, and ink density have to be taken into account with conventional, analogue press methods – digital printing does not suffer these limitations.

‘As the market trends toward shorter runs and more variable on-demand printing, that’s where digital comes in, allowing the small- to medium-sized printer to have the opportunity to capture more of that business. Not only do you get rid of several production steps, but you drastically reduce make-ready waste, and the time for setup, and eliminate the need for CMYK plates. More importantly, you reduce lead time for your customers; they can have a proof print in their hand within minutes, and the whole job within a couple of hours. This would be impossible with flexo.’

The successful ‘Share a Coke’ campaign by Coca Cola with individually named labels, and the recent move of Marks & Spencer towards digital labelling of their retail products, can be seen as the tip of the iceberg; more and more retail outlets will be demanding this flexibility.

Environmental concerns

The ability to offer customers shorter lead times, shorter runs of up to 50,000 labels, and quality comparable to what they had been getting is an opportunity many print providers will find very attractive.

The move to digital can also be seen as a benefit to the environment. Targeted print, ie print-only-what-you-need, does away with all the wastage associated with make-ready prints and even obsolescence wastage, as labels and other marketing materials are superseded by new data, specifications, ingredients, dates etc. Instead of holding large inventory of printed label stock, the end user can now print precise quantities on demand.

The future

Erik Norman, president of RTI Digital said: ‘Our Vortex range is all about bringing a wider capability to the modern print provider, with an affordable price tag. The new single-pass Memjet technology that we have incorporated into our range, and which has been successfully rolled-out over the past two years or so, is enabling our customers to gain business that they would not have been able to take before. It is not so much a question ofreplacingold methods, asaugmentingthose methods, and providing those customers with new business opportunities.’