The label sector is one of the few in print that is gaining in strength. With the right client base and the right technology, there could be opportunities for digital printers to grab a slice of the action.

Improvements in digital printing technology have made label production a potential direction for commercial printers. As in many other sectors, the trend with those that purchase labels is towards smaller runs; label converters themselves are increasingly switching to digital printing or at the very least adding digital to their existing offset and flexo capabilities; visitors to the last drupa would have been struck by the number of new digital label presses that were being launched, often by companies that have little or no formal background in the sector.

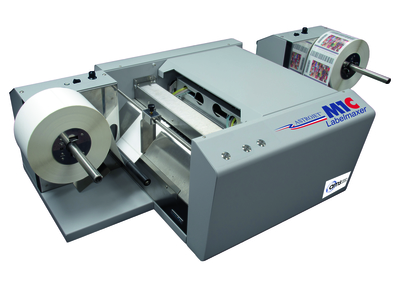

There is an opportunity here for commercial printers of all sizes to diversify therefore, and technology paths need to be assessed based upon volume and application. At the higher end are machines such as the FFEI Graphium, EFI Jetrion, Domino Printing’s N Series, HP Indigo 20000 and WS6800, Heidelberg Linoprint L, Epson SurePress, Screen TruePress, and Xeikon 3500. Becoming more prominent in the market is much more easily affordable Memjet-driven technology, such as the RTI Vortex, Colordyne CDT 1600, and the AMS M1C Labelmaxer. There is a variety of toner-based systems, with OKI-based systems such as the iSys Edge850 (available from Intec in the UK), and Primera’s CX series. Then there are wide format options such as Roland DG and Mimaki’s print & cut devices.

The point is, many commercial printers are turning label work away, when with only a limited outlay they could potentially cater to a consistently strong area of need for clients that they may already be printing a range of other products for.

James Whitehead, product manager at Fujifilm Graphic Systems UK, commented: ‘Many commercial printers have perhaps supplied the label market, albeit with wet glue label or shrink sleeve products, printed lithographically. Their customers may have requested self-adhesive labels which the printer has been reluctant to, or unable to, produce without the skills and knowledge of flexo.

‘The advent of UV inkjet digital label print has brought the capability to produce self-adhesive labels into easier reach for the commercial printer. The simplicity of digital production combined with the robust in-use properties of a UV inkjet ink which mirror those of UV flexo, allow a simpler step in to the market.’

However, label production is not simply about the printing, he warned. Additional process such as varnishing, lamination, cold foiling or die cutting are steps also required to succeed in the label market, and this is something that commercial printers should consider when they expand their offering to label printing.

‘Inline digital label print and conversion is a logical concept and Graphium provides this,’ he continued.

‘With a client base to draw on, print technology which is accessible and simple to use, and inline label conversion as standard, the step into digital label production could be simpler than expected for commercial printers, and should not be left unexplored.’

Roland BN-20 printer and cutter

Lower level

The FFEI Graphium to which Mr Whitehead refers, however, is a substantial piece of label printing technology. It carries a ticket price that will make it unaffordable for a great many printing companies who might see labels as a small but lucrative add-on to their existing commercial business.

In such a scenario, something like the £8000 M1C Labelmaxer, manufactured by Astro in the US and sold in the UK by Addressing & Mailing Solutions (AMS), makes a great deal more sense. Based on Memjet printing heads, it can print full colour with full bleed at a rate of 300 mm per second, across an eight inch print width.

‘We’ve got a couple of companies out there, small commercial print guys offering a label service to local businesses,’ said John Mathews of AMS. ‘It gives them the flexibility when they just need that very quick short run of something from artwork supplied and they can produce some labels in a very short space of time. The people we have really sold it to are label converters that want to do high quality but short runs – 1000 labels with a logo on and they can just do it. We’ve also sold machines to companies such as fishing tackle suppliers that are doing their own packaging, and just need a label with current information like an expiry date.’

Commercial printers will always be keen to scrutinise the quality of output, and Mr Mathews points out that the M1C Labelmaxer is not designed to produce the kind of quality that you see on the supermarket shelves; for short runs for local businesses however, it is more than adequate. Given the comparatively small capital cost, these levels of printing system are often purchased just to see if business can be brought in for them, rather than the company already having the work waiting. ‘Many people buy it before they have got the work for it, so they can offer it,’ Mr Mathews confirmed. ‘It means that they won’t have to turn that kind of work away.’

AMS sells the M1C Labelmaxer as a standalone printing system generally, but it can be purchased as a package with finishing units such as slitters and rewinders, which are supplied by Labelmate in Belgium, through the dealer Auto I.D. Systems in Liverpool.

Wider format

The alternative route to short run labels is to consider a wide format inkjet printer, with manufacturers such as Epson, HP, Roland DG and Mimaki all producing inkjet systems that can be turned to good use as label printers, as well as offering many other potential applications too.

For less than £6000, a printer can invest in the Mimaki CJV30-60 printer/cutter, a 610 mm wide integrated printer/cutter that is able to output very high quality labels onto self-adhesive stock using process, metallic and white inks. Mimaki also has 1 metre, 1.3 and 1.6 metre versions available.

Commercial printers considering getting into labels with Roland can choose from various levels of print and cut machines, all ideal for label production; from the desktop BN-20, which has a maximum print width of 51 cm, can be used with metallic and white inks, and has integrated precision contour cutting, to the free-standing, best-selling VersaCAMM VS-i range and VersaUV LEC-330/540. The widest, fastest and most powerful integrated print and cut device, the SolJet Pro4 XR-640, is also applicable to the printing of labels.

With both the Mimaki and Roland equipment, the contour and kiss cutting capability is a key feature for the label market.

‘Rapid advances in digital print and cut technology are transforming the business of label printing,’ said Rob Goleniowski, Sign and Graphics business manager for Roland DG. ‘For commercial printers considering getting into label production, a Roland print and cut machine will allow them to create high quality digital labels of any size, shape, colour and quantity without needing to get a die made. It enables the production of short print runs cost-effectively; colour matching can easily be incorporated, along with special effects such as metallic spot colours, white ink for printing on to clear materials and even a gloss ink for a spot varnish or embossing. Even one-ups, prototypes and initial proofs are of production quality.’

The automated print and cut function of such machines means that users are freed from the extra pressure of having to learn how to produce a product up to market standard while trying to break into that new market, as even the most complex and intricate graphics are precision cut. Furthermore, since these machines automatically print, reposition and cut graphics on the same device, a commercial printer will have to spend less time overseeing the new area of production.

From an ROI perspective, investment can be lower as printers are investing in only one machine with integrated print and cut capabilities rather than a printer and separate cutter. Warranty costs may also be lower as only one maintenance contract is required. Having both print and cut functionality in one system also saves valuable floor space.

The great benefit of the wide format machines is that they can potentially open many other doors, aside from labels. In particular, the versatility of the print and cut machines, with their ability to print, kiss cut and die cut on a variety of materials including self-adhesive vinyl, shrink film, PET and BOP, makes applications such as decals, heat transfers, cut lettering, contour-cut window, floor and exhibition graphics, POP, promotional items, and interior décor items, all become a realistic possibility.

If a step in the label direction is of interest, then researching the market is the first step, whether that is finding out more about the technology, the applications, the substrates, or the needs of the client base. It might be that a visit to the Industrial Inkjet Symposium on label production in October is a good place to start. John Corrall, managing director of Industrial Inkjet Ltd, said: ‘The symposium will be a must-attend event for digital printers actively targeting the labels market and will cover wide-ranging issues. We wanted to make it something more than a business level discussion. We want to offer practical help and advice from real world experience. We wanted to describe the issues that will appear, the pitfalls to avoid, and some solutions that we know work. It will be based on first-hand experience from world-leading experts.’