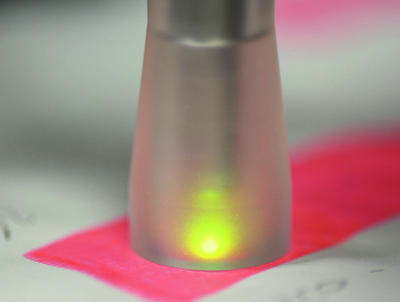

Here a scanner shines a green laser onto the red sample strip, and detects the yellow wavelength being returned

A sparkling new inkjet fluid developed at Cambridge University will shine with a true laser light, if you illuminate it properly. It’s got big potential in security printing and maybe future TVs. Simon Eccles talked to its principle developer, Dr Damian Gardiner.

A new digitally printed weapon may be about join the fight against counterfeiting. Printable inkjet lasers have been developed by a small team at the University of Cambridge and are now being commercialised through a spin-off company called Ilumink (www.ilumink.com). They look attractive, they can be authenticated by hand-held scanners, and they’re almost impossible to fake.

While security printing is the initial application for the laser-emitting ink there are intriguing hints of future potential, including bright TVs and signage that can be applied as wallpaper, and medical/pharmaceutical products.

A team led by Dr Damian Gardiner has developed the new ink and filed patents on it. Dr Gardiner is a Royal Academy of Engineering Enterprise Fellow at the University of Cambridge Engineering Department and for the past couple of years he has been working to develop the ink for industrial use and then to commercialise it.

The work has involved close collaboration with the University’s Inkjet Research Centre, in particular Dr Kai Hsiao and Professor Ian Hutchings. Since March 2013 Dr Gardiner has worked to commercialise printable lasers with an £80,000 grant from the Royal Academy of Engineering. Ongoing funding is being provided by the Engineering and Physical Sciences Research Council. The commercial company he set up, Ilumink, has two employees including Dr Gardiner. It currently exists primarily to seek partners to bring the laser ink to market, including through licensing and co-development.

What’s a printable laser?

This is a UV-curable ink containing a liquid crystal material that can be formulated to emit a very narrow peak wavelength of light when illuminated by an external laser generator. The emitted wavelength can be tuned precisely over a range of colours and then registered for use with a particular product.

‘Some people assume we’ve printed a laser beam, but no, it is true laser light, but not what you see from a laser pen,’ Dr Gardiner explained. ‘It’s not a well-collimated beam. It can be confusing to a layperson, when you talk about pumping one laser with another laser – what’s all that about?’

What you see (or not for infra red) is a scattered, unfocussed reflection, formed of light all of the same wavelength, with the waves all in phase. It really is a laser, but looking at it won’t damage your eyes.

Demonstrations on YouTube show Dr Gardiner shining a laser light on a box of Chinese tea printed with one of his laser marks. The bright reflection shows a very obvious green to yellow colour change, but a measuring instrument identifies that it has a very clean spike at a particular wavelength.

Dr Damian Gardiner

Dr Damian Gardiner

Once the principle of the liquid crystal laser emission was established, Dr Gardiner looked around for an application. ‘Originally we just thought wouldn’t it be great to print a laser, without too much thought of what it could be used for,’ he said.

A lot of work went into getting the liquid crystals into an emulsion form that could then form the basis of a jettable ink. The first attempts required careful surface preparation and jetting at high temperatures of 100 degrees C, but they generated the laser effect as hoped.

Since then a lot of the work has gone into ‘ruggedising,’ turning the ink into something stable that’s practical for more or less standard inkjet heads, and which can be UV cured to withstand the rough and tumble of real world printing and packaging without rubbing off or fading. Today’s ink can be jetted at 70 degrees C using a standard Fujifim Dimatix printhead.

How laser ink works

Dr Gardiner’s speciality is liquid crystals, which he describes as ‘self-organised atomic matter.’ The ink he calls a ‘structural fluid.’ The important part is that ‘chiral nematic’ liquid crystals in the fluid are formed from molecules that spontaneously align themselves into helical (spiral twisted) structures. This twist affects the way they reflect light, as it forms resonant cavities, which are a key stage in laser emission.

A similar effect, though not true lasers, is found in nature where some butterflies’ wings and beetle wing cases reflect iridescent colours, in intense blues, yellows, reds and greens, that are created by very fine grooved structures rather than pigments.

When a laser light source (called the pump) strikes the crystals’ helices, it is bounced around and re-emitted at lower wavelength. By varying the twist of the crystals, it’s possible to precisely control the emitted light’s wavelength: the tighter the twist, the smaller the twist and the bluer the laser. Additives to the liquid control the degree of twist.

Ilumink’s graphs show that a range of wavelengths can be achieved across the visible spectrum from blue, green and red and down into infra red.

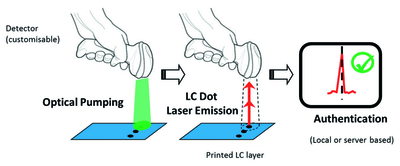

The illuminating laser would be built into a security scanner, together with a reader that measures the exact wavelength being re-emitted. The pump laser always needs to be a higher wavelength, so to get a blue emission you’d start with an ultra violet laser. However you’ll always get the same wavelength out of a particular laser ink, so a single source laser in a scanning device can be used with a multitude of different inks.

The inks can be individually tuned to emit a wide range of visible and infra red laser wavelengths

The inks can be individually tuned to emit a wide range of visible and infra red laser wavelengths

Printing for packaging

‘In principle any packaging that can go through a normal print line can be printed,’ said Dr Gardiner. ‘You may have to put a base varnish down first. At present it’s a UV curable base varnish, but it may be that UV cure isn’t needed.

The ink can be printed by standard inkjet printheads, which could be used on a packaging line to add security markings to packaging for high value goods or pharmaceutical drugs, or banknotes and similar items that that are susceptible to counterfeiting. ‘You cannot fake this by scanning and reproducing it,’ he stressed.

There’s even the possibility of using multiple inkjet heads, each with a different ink, to either use on the same product to give multiple laser responses (also detectable by instruments), or to easily swap between product lines.

Setting up an inkjet is relatively cheap and heads can be positioned practically anywhere on a printing, finishing or filling line. Unlike hologram markings, it can be used for long or short runs. Holograms are no longer regarded as particularly secure markings anyway. Dr Gardiner said that offset and flexographic laser inks are being considered for future development too. ‘You could even apply it with a roller,’ he added.

Iridescent effects

A spin-off benefit of the ink is that even in normal light it can be given an attractive iridescent rainbow effect, especially when printed over a black or dark coloured base laser. The effect can be tuned by dyes, so for instance ink printed over a green background might reflect red or blue.

So anyone can see that there’s a security marking in normal daylight, even if it takes a laser to trigger the main effect. As the markings are printed by inkjet, they can also contain variable data, such as unique numbers or codes.

Dr Gardiner calls this ‘multi-level authentication,’ where the markings can simultaneously be visible to human eyes or smartphones, while being printed over machine readable codes (QR or barcodes for instance) and then delivering a precise laser emission when stimulated by another laser. Alternatively it’s possible to formulate the ink without the dyes so it’s not obvious, making covert security markings.

Hand-held readers can be used to shine a laser light onto the marking and then detect the precise wavelength being re-emitted. If the reader doesn’t detect a laser reflection, or if it’s the wrong wavelength for that product, you know you’re holding a fake.

Initially the detectors are likely to be relatively expensive and used by customs and bank officials and the like, but Dr Gardiner reckons that more affordable, if less precise readers could soon be developed for use in stores and warehouses. He even envisages a smartphone app that works with the built-in cameras, not to detect the laser effect but to detect other optical characteristics of the markings.

How the scanner uses a source ‘pump’ laser, and then reads the peak wavelength of the emitted laser from the ink

How the scanner uses a source ‘pump’ laser, and then reads the peak wavelength of the emitted laser from the ink

Laser display board

Fans of Radio 4’s I’m Sorry I Haven’t A Clue’ will be familiar with its mythical ‘laser display board.’ This ink could make it come true. If you print with red, green and blue emitting inks, then illuminate them with scanning laser beams of the appropriate input wavelength (presumably UV to avoid swamping the display with reflections), you’ll get a bright and very pure RGB image that requires no power to the screen area.

It would be like today’s digital projectors on steroids and it should work at up to very large formats, possibly in daylight. So far this hasn’t been tried and it’s all rather hypothetical, but if it works it could shake up both the entertainment and the signage world.

‘The next stage for the ink is finding external investment’, Dr Gardiner concludes. ‘We need to be sure we’re solving somebody’s need rather than blindly developing technology in the lab.’