Opportunity abounds in digital direct to garment printing, those in the sector say, and for a comparatively light initial investment you can get under way. Real success depends on creativity and marketing however.

The Printwear & Promotions Live show, which took place at the NEC over three days in late February, is a good place to start for any commercial printer considering jumping into digital Direct to Garment printing (DTG), and not just for the perma-grinning young dancers who take to the stage three times a day to perform energetic routines that showcase the latest in a number of garment suppliers’ printwear ranges.

Yes, the event has its own fashion show, although you are not that likely to mistake Birmingham for fast-rising catwalk capital Barcelona, let alone New York or Paris. But everything an interested print entrepreneur would need to know about and look at was at Printwear & Promotions Live: the machinery, the garments and their suppliers, online design and ecommerce and business advice.

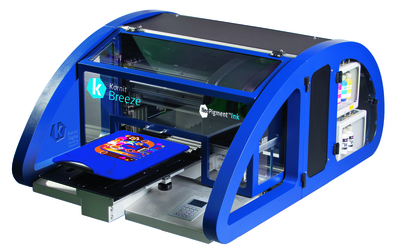

Those selling printing machinery into the digital DTG field claim that its potential is huge. Digital currently accounts for only about 7% of the total market for printing directly to garments. It is the kind of business that can be set up with a reasonably moderate sum of capital (around £10,000 can get you going), and such are the margins that are possible, that a well-thought out business plan can realise an ROI in a matter of months. For example, Kornit Digital, which sells comparatively costly DTG systems starting from €40,000 through Adelco and Lineker Machines in the UK, cites a screen printer that invested in digital printing technology and came up with a new business model. It purchased Kornit’s entry-level Kornit Breeze and a dryer, selling 30 shirts a day for €15 or €20 each. Its monthly profit can be around €7000, giving it a break even on its €40,000 investment in six months.

There are other ways of printing onto garments – screen printing and transfer printing for examples. Digital DTG has advantages over both, in that, compared to screen, it is a deskilled process and it can cope with runs of one garment, and that, according to Robert Miller of J&B Sewing, the quality of DTG is better than transfer printing.

Against this, Jim Nicol of TheMagicTouch, which does not sell a DTG printer, points out that the investment for a DTG machine is higher than transfer printing, and some are limited in terms of the fabrics they can print upon. He recommends getting a clear warranty definition, especially with regard to replacement print heads.

Nevertheless, Mr Miller said that J&B Sewing, which sells Brother and AnaJet printing systems, is fielding an increasing number of enquiries from printing companies that want to add digital DTG to their armoury, and many of them have a head start: ‘The opportunities are tremendous because they have a customer base already. It’s not like starting out normally. They can say to their customers, we now offer this service. It’s complementary. They have the graphics skills, they have the marketing skills, and they have already built the business.’

Oliver Luedtke, marketing manager EMEA for Kornit Digital Europe, observes that the market is moving in the right direction for a successful entry into digital DTG, saying: ‘Considering trends towards personalisation, smaller production quantities and environmental consciousness, the odds are very positive that a service-oriented entrepreneur can become successful in this business as long as a few ground rules are considered.’

Oliver Luedtke, marketing manager EMEA for Kornit Digital Europe

Oliver Luedtke, marketing manager EMEA for Kornit Digital Europe

Hardware

So what are these ground rules? First comes evaluating and choosing the right hardware, something any digital printer is well accustomed to already. As was alluded to before, there is quite a wide range of equipment to choose from, and the choice is really going to come down to the expected volume of garments you will be printing. A tshirt printing system can range from a few thousand euros or pounds for a remodelled large format printer, up to Kornit Digital’s highest specification machine, the Avalanche, which costs a cool €210,000.

It is not just about the printing press however. Before printing a garment with a digital press, the fabric needs to be pretreated, especially if the garment is not white, in which case white ink will have to be put down first before the colour inks. The pretreatment liquid acts as a barrier to stop the ink from soaking into the fabric, as well as helping to produce a more vibrant colour design on the garment.

There are several different ways that pretreatmentcan be applied, such as by hand using a spray gun, a separate system like the Viper pre-treatment machines sold by DTG Solutions alongside its Epson SureColor SCF2000 direct to garment printer (again, there are pre-treatment systems suited to smaller and larger shops), or with pre-treatment built into the printing system itself, which is the approach taken by Kornit Digital. The advantage of not applying the pre-treatment manually is twofold: both speed and

consistency of application across the garment. This is another area where projected volumes must be factored into the purchase decision. The other major investment, although generally considerably less expensive than the printing press, is a heat press. This must be used to dry the garment after pre-treatment, and again after printing; it also helps to bind the ink to the fabric. A heat press is usually bundled with the DTG printer, and might cost anything from a few hundred pounds up to more than £1000. For even greater volumes, a tunnel dryer might be recommended.

You should not forget about workflow software either. You might get a job requiring 20 personalised shirts to be printed for a team or a company, and this can only be handled profitably if you can efficiently create 20 different print files from a single template. Modern workflow software can make these kinds of jobs simple, as well as replacing colours and transparencies. It can connect to a clipart library, generate a preview of the garment, keep track of inventory and much more. Investing in good workflow at the start can save many man hours further down the line.

The Kornit Breeze

The Kornit Breeze

Garment choice

Next is an area that will be foreign to many commercial printers: the garments themselves.

Kornit Digital’s Oliver Leudtke commented: ‘Garments as a substrate can be a bit tricky. There are so many different types of fibres, so many different ways to turn them into yarn, and so many different ways of turning the yarn into a garment. Enzymes and additives are often used to create the desired soft hand feel. Plus, most raw garments are shipped overseas so they will need to be treated with preserving agents.

‘This all multiplies up into a vast array of different materials and qualities on the market, so picking the right garment type and brand should be a focus area if you want to get into this business. You need to build up expertise in this area.’

Most printing system suppliers should be able to help to some degree when it comes to choosing the supplier of the garments you wish to offer. There are many different brands in this market, including big names such as Fruit of the Loom and Brook Taverner. It will also depend on what exactly you plan to sell – is it t-shirts? Hoodies? Trousers? Sports wear? Digital DTG printing uses water-based inks that can be used on a wide range of fabrics, from cotton to wool to silk. The market you plan to target is going to play a very significant role in the garment supplier you decide to work with.

You will also need to sell your garments, not just print them. There are two particular aspects to this: setting up an effective web shop; and having the kind of attractive design and garments that people will want to buy at a price that makes you a healthy margin. Help on the former aspect can be found at a company such as DecoNetwork, who DTG Solutions partners with. It is a fully hosted web technology that has been built specifically for the custom decoration industry, and has more than 18,000 sites globally. Included in the company’s tools is an Online Designer that allows customers to personalise garments at their leisure, and comprehensive order management tools, suitable for small and large companies targeting B2B and B2C markets.

The key to success is good design and good marketing, according to Robert Miller of J&B Sewing. He said: ‘Work out the marketing first. It’s not about printing t-shirts, it’s about selling t-shirts. People come and say to me, I’m starting a website. It’s more than that. It’s about good designs, good marketing. Search Engine Optimisation. The village idiot can print t-shirts, but if you have good design and good marketing you will make money.’

To this, Kornit Digital’s Oliver Luedtke added: ‘You need to understand the number of shirts you can produce and the price that you can sell them for. If you’re able to get £20 to £25 per shirt, that’s printing money. If it is only £6 to £7, that’s more difficult. Essentially it’s about creativity. The shirt is a piece of fashion and an expression of individual style.

When it comes to attracting new customers, attractive designs are as important as a good print quality.

‘How do you make a shirt that you can sell for high prices? That’s even more important in the business model than how many shirts. You need an end user base, ideally through a web shop. Try to make a connection with textile designers that can work up some unique pieces of fashion for you. Watch the market carefully – what kind of shirts are selling well in your country? Check places like the big online retailers in order to establish present day trends. And, take some time to ‘play’ with the machine and bring out the best effects and printing results. This is what makes the difference between being able to charge 20 cents for a print and selling a tasteful piece of fashion for €30.’

Surecolor SC-F2000 t-shirt printer

Surecolor SC-F2000 t-shirt printer

The plan

Essentially, a move into digital DTG printing requires a print company owner to do the research and the sums in advance – to formulate a business plan that enables him to sell the right number of garments at the right price, with an eye for design and an ear to the ground that facilitates spotting and grabbing potential big selling ideas. Printers can also broaden their experience by gaining a working knowledge of different fabrics and their printing characteristics.

There are many opportunities, says Robert Miller: ‘Do not ignore the value of sales to local businesses, schools, colleges and clubs. Sending a sample shirt with company logos, school badges, pub signs, etc. can be a very cheap and directly applicable advertisement.

These channels alone can produce hundreds of sales. The great benefit of garment printing is it is simple to produce a single sample that will allow the customers to actually see what they are going to receive before placing the full order.’

Hi, I’ve been trying to get my hands on a DTG printer and still thinking of buying one specially now that we have growing orders and this helps me scale my business.. thanks a bunch.