IIJ manufactures a range of print modules from 72mm to 702mm wide up to 80 metres a minute print speed

Opening new doors for flexo presses by integrating digital modules

New regulations from Brussels coming into force at the end of this year will have a far-reaching impact on brand owners – particularly those in the food industry – that will change the face of packaging across Europe.

And for many international manufacturers, it will involve upgrading standard business procedures to cope with Euro directives that will be introduced for minimum font sizes on food packaging. These cover, for example, details such as ingredient lists, nutrition information and contact details, as well as labelling requirements for foodstuffs sold via the internet. Instead of putting contact information in four languages, from 2015 there will only be enough space to fit one language per piece of packaging. That means manufacturers have four times the number of separate designs to run.

The relevant documentation comes under Regulation (EU) No 1169/2011, which will replace the current requirements for the labelling of foodstuffs set out in Directive 2000/13/EC and the nutrition labelling requirements of Directive 90/496/EEC. Translated down to the printer, run lengths will become a quarter of what they were and set-up costs will go through the roof. Suddenly, digital looks attractive and will become a ‘must have’investment for thousands of printers across Europe, yet many will not want to invest in complete new systems, so that is where Industrial Inkjet Ltd (IIJ) can help. IIJ, which is based in the UK, is at the forefront of advising printers, suppliers and brand owners in the packaging market with this EU directive, working directly with one of the biggest food suppliers for the last four years in a pioneering project to enable it to adapt to change.

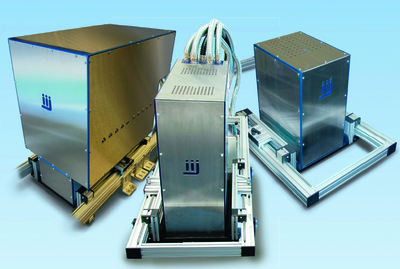

The award-winning IIJ digital label module

The award-winning IIJ digital label module

Like much of its work, which is so highly secretive and advanced that it cannot even mention locations, yet alone names, this expertise is enabling IIJ to deliver dramatic year-on-year growth for itself and partner Konica Minolta while at the same time building a considerable reputation for itself in its specialist markets.

Take printing on wood laminates as just one example. While companies are suddenly waking up to the idea of using new processes to add tactile and lustre effects to wallboards, furniture and flooring, it is a market where IIJ has been excelling for years. Indeed, the InPrint Show in Hannover from 8-10 April this year will bring back happy memories for IIJ, which first displayed printing wood laminates on a customer’s stand seven years ago at Ligna in the same city.

Industry veteran John Corrall, managing director of IIJ, started the company eight years ago, providing sales and technical support for Konica Minolta inkjet for all markets outside of Asia. Dealing largely with OEMs, the company manufactures inkjet print engines and already has an installed base of well over 100 systems.

IIJ is highly active in the narrow web colour digital label sector, providing digital label modules for flexo presses from companies such as Gallus, Nilpeter and Mark Andy. But when it comes to fitting digital to existing presses, colour is still a niche market, and monochrome remains king. IIJ maintains that the key to this market is to supply a digital module that can be integrated into a press with no more difficulty than existing analogue technology.

The digital module then has a wide range of jobs to do. It may print variable text in one colour (often a spot colour) with low-migration ink (an important requirement for food packaging). It may need to print white, spot varnish, or even security inks (IR-readable, or UVfluorescent).

‘Colour inkjet is not yet making the inroads into the label marketplace that everybody expected,’ said Mr Corrall. ‘Mono is still very much cool and exciting.’

That is where the IIJ MonoPrint i series comes into its own. Working with a large number of professional ink manufacturers, IIJ tests inks for almost every application that their customers can imagine. With zero set-up time on repeat jobs, digital comes into its own whenever runs are short or variable data is needed. But using white, fluorescent or varnish inks, ‘premium’ effects are easily achieved. IIJ has inks for coated paper stocks, films, foils, metal, plastic, glass or wood.

A MonoPrint 352i fitted to a Nilpeter press

A MonoPrint 352i fitted to a Nilpeter press

The MonoPrint i is a compact unit that nestles securely on to a press, and with a typical print speed of 80 metres per minute there is no restriction on the speed of the press.

Providing fully variable printing from databases or multi-page PDFs, the system can be supplied with sophisticated verification systems to verify print against the source data used. ‘The print engines are reliable and have tremendous uptime,’ said Mr Corrall. ‘We have lots of customers reporting that on an average shift there is zero maintenance needed – zero down time. The more they run, the happier they are.’

A typical example is duplex printing a UV fluorescent ink and a visible black ink for a security printing application with in-line camera verification and automatic quarantine of ‘bad’ print. This system has already run for more than two years with minimal maintenance. It is based on an AB Graphic press. It is a high volume ‘security’ label for a common product used in everyday lives – most people don’t even know it’s there!

As well as the narrow web label market (typically 250 to 350 mmprint width) IIJ says it has units for the flexible packaging market (up to 700 mm print width) and can supply even larger machines (up to perhaps 1.6 metre width) for folding carton applications. For smaller carton applications, IIJ partners with Keal Equipment to provide a turnkey conveyor solution.

IIJ MonoPrint i unit pricing starts in the region of £50,000 for a smaller unit. Pricing depends on the required configuration, which includes print width, speed and number of colours required.