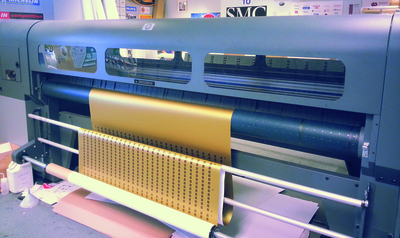

Jack Murphy with one of the company’s HP printers.

Berkshire company Bullseye has diversified into wide format printing after decades as a specialist in trophies, enabling it to build a trade print service.

If there was a trophy to be awarded for successful diversification into large format print and finishing, Slough-based Bullseye Print and Awards would be printing their own name on it.

The company, which produces the BBC Sports Personality awards, has been creating trophies for 35 years, and during that time found that customer demands for matching suites of materials included increasing requirements for wide format printing.

‘We spent lots of time working with people who were running special events, such as awards nights for sports clubs and blue chip corporate clients. We were asked more and more about print, especially banners, and initially we outsourced it,’ explained managing director Vince Murphy.

‘Unfortunately this proved expensive and unreliable, so we took the leap and invested in a wide format printer so we could do the work ourselves.’

The company has worked closely with large format print and finishing reseller CWE Solutions over the last five years, drawing on its expertise, products and service to help grow the Bullseye printing arm.

CWE is a HP Preferred Partner and also sells systems from manufacturers such as Epson and Seiko.

Bring wide format printing in-house has not only enabled Bullseye to offer additional services to existing clients, but also to build up a new trade customer base, many of whom did not even know that Bullseye also made trophies.

Over the last few years, the company’s investments, all purchased through CWE Solutions, have been substantial. In 2013 there have been two HP systems – a HP FB700 UV printer in April 2013, and a HP Z6100 Aqueous printer in July 2013. An Esko Kongsberg iXL-44 CNC cutter was purchased in May 2012, a Seiko ColourPainter Solvent printer in April 2011, and a Mutoh Viper Sublimation printer (which is soon due to be replaced by a new Mutoh VJ1638W) in December 2009.

The Esko Kongsberg cutter is saving Bullseye up to 100 man hours a week. Below: the HP FB700 UV printer arrived in April 2013.

The Esko Kongsberg cutter is saving Bullseye up to 100 man hours a week. Below: the HP FB700 UV printer arrived in April 2013.

‘The support from CWE Solutions has been fantastic, helping us look at the right machines to buy, and being honest about what they can and can’t do,’ added Mr Murphy. ‘Their expert installations and ongoing support have also been second to none.’

The company eventually found that it had grown its printing arm so much that finishing was becoming difficult, with everything being hand cut. Having discussed its requirements with CWE Solutions, Bullseye went ahead and bought a Kongsberg iXL-44 CNC cutter.

The Kongsberg now runs for eight to ten hours a day, and marketing director Jack Murphy said it has become a crucial piece of equipment for Bullseye.

‘We run everything other than digital paper through it: flags, banners, sticker vinyl, reboard FSDUs and so on. At the moment we’ve got a job for 300 flags, which previously would have had to be hand cut. With jobs like these, the Kongsberg is saving us between 50 and 100 man hours a week.

‘As well as the basics, the cut and crease facilities have opened up a new market for us. We’re now printing boxes on low quantity runs on the HP FB700 and finishing them on the Kongsberg, for both point of sale and sales pitch samples for the pharmaceutical industry.’

Bullseye is also working more with foamex – either printing and cutting to shape itself or taking in trade orders from other companies who do not have their own flatbed printer or cutter. It is also cutting preprinted work to shape, and can advise others on artwork preparation to set up a job for cutting.

‘We use the HP primarily on foamex, cardboard, banner vinyl, and sticker vinyl, and it’s great for reliability and speed. We can even leave 50 metre rolls of vinyl to print overnight without any worries. But it’s great for other materials too – we’re now printing onto carpet for shop fitting and exhibitions, as well as MDF.

‘We find it a lot cheaper to run than our old printers, and a competitive price is crucial in the trade market.

‘The colours are fantastic, and the precision is astounding. We print our own medal centres – they can be as small as 50 mm with fine text. We’re also now experimenting with promotional gifts like mint dispensers and fridge magnets.’

Everything is now finished in-house, and Bullseye is able to offer trade finishing for fabrics, banners and foamex.

Mr Murphy continued: ‘With the Mutoh we’re working more with fabrics, using the sublimation process to do one off samples of cushions for customers to pitch for work, even on suede. We print them, and use the cutter and in-house seamstresses to finish.

‘In general we’re moving towards more sustainable and environmentally friendly printing, and gearing up for more work with fabric. We go where the customers want us to go.’