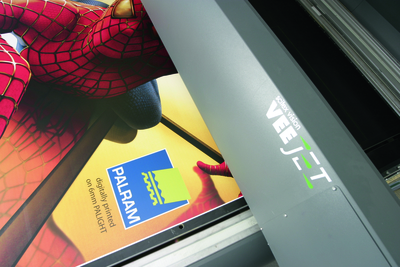

Thermoplastic substrate supplier Perspex Distribution has witnessed a surge in interest in wide format flatbed printers, and emphasises the importance of feeding such systems with quality substrates.

Diversification is a key consideration for those looking to take advantage of the recent ‘mini boom’ in wide format flatbed printers.

Opening up a world of rigid substrate material such as Perspex, aluminium composite and PVC foam, wide format printing enables printers to start selling into new markets such as point-of-sale, exhibition or signage. Diversifying your product range can increase margins and help you to take advantage of lower machinery entry costs.

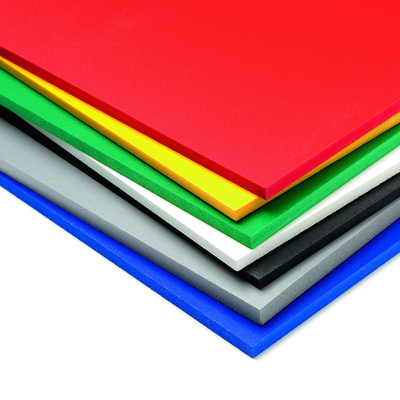

When it comes to substrates, it is possible to print an image on any rigid material, so long as it is flat and its dimensions fit both the printing width and height tolerances. Wide format flatbed printers can print on materials from Perspex to PVC Foam board, so whether increasing your product range into existing customers or opening opportunities into new markets, substrate printing really is key.

Rigid substrates

As print machinery technology evolves, print service providers require substrates developed to produce the best possible finish for digital print, wide format and screen printers. Perspex Distribution recognises that printers are making significant investments in the latest print machinery; it is therefore paramount to provide them with the best materials on the market.

While it is possible to print on practically any substrate, the company strives to keep ahead of the market with products that offer long-term performance, including such products as Palight PVC Foam and Alupanel Aluminium Composite. Product development for substrates is now for ‘flatter and whiter’ sheets that remain dimensionally stable while being printed.

Perspex Distribution’s entire white Alupanel aluminium composite now comes in an ultrawhite finish as standard, providing for brighter digital print, as well as having an easy peel film for simple time saving in the workshop. Available in a number of thicknesses, specialist sheets can be used for applications from hoarding, signage and load bearing exhibition stands.

PVC Foam offers a lightweight printable sheet ideal for flatbed print. It is also easy to cut and fabricate, making point of sale and signage ideal applications. The attraction of potential growth for printers using these substrates is clear. However, after investing heavily in machinery, it is important that companies choose the right supplier to ensure high end product quality and service.

Perspex Distribution’s materials for flatbed printers are manufactured in the UK, ensuring quality production, environmental accreditations and local availability for stock.

Time and Cost Saving

Print buyers and end users want to see ever faster turnaround times, better quality print and added value products. Before direct to substrate flatbed printing emerged, graphics were printed onto vinyl, cut to shape, then applied to a rigid board and laminated. Whilst effective, it was time consuming, reduced profit and increased turnaround time. In today’s world, printing onto rigid substrates direct leaves a lot more room for margin and increases productivity many-fold, increasing the money-making potential of such products.

The productivity boost and better margins possible from printing on rigid substrates are very attractive for those looking to purchase their first wide format printer, and existing owners alike.

Markets

Markets such as point-of-sale signage and exhibition stand work are logical new markets that can be entered with rigid substrates. When establishing what markets to approach, first establish what type of productsyou could supply to your existing customers, to increase their spend with you. Find out more about the projects they get involved with and use this to research areas you could move into.

Opportunities exist to get into niche printing areas such as directly printing onto aluminium composite hoarding panels to disguise construction sites, or printing photos onto clear Perspex as a high end alternative to canvas prints.

Machinery

Manufacturers of print hardware are continually introducing new ranges of machines, which drive down cost while at the same time become ever more productive, with faster output speeds and less ink usage, and produce higher quality graphics. The UV ink used within the printers is also becoming substratefriendly, making the print more efficient and enabling a variety of finishes and effects.

For those wishing to further increase their ability to work with rigid materials, laser cutters and CNC routers enable fabrication work to be carried out – bending, cutting and forming sheets – opening up the ability to increase your range of finished products and potential markets. Even LED lights can be introduced. Suppliers such as Perspex Distribution will supply training, support and even layout drawings to support installation and projects.

Other sectors such as the signage industry are getting in on the act – wide format flatbed printing has been described as the sign industry’s newest tiger sector, so established printers should move quickly to consider if this is a viable market for them.

The Perspex service

After investing in machinery, it is important that companies choose the right supplier to ensure high product quality and service. Few people would buy their machinery from a supplier they had never heard of, so why risk feeding your machines with substrates from unknown sources?

The market is being flooded with unbranded budget substrates, often manufactured in the Far East, and Perspex Distribution believes that the quality control and guarantees, should unforeseen circumstances occur, are questionable at best.

As specialist suppliers of thermoplastic substrates, Perspex Distribution’s products are largely sourced from European manufacturers – its Perspex has been made at its own manufacturing plant in Lancashire for almost 80 years. It does not just distribute materials – it gives in-depth technical advice about products and applications, working alongside print companies to understand how to get the best results. The local supply chain ensures optimum quality control, as well as fast availability for special requirements – supporting print strategies that demand reliable supply of quality substrates to end users.