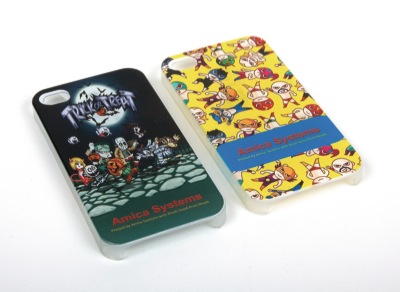

Phone cases are just one of the different products prnters can offer with Print’s systems

Renowned in the promotional gifts sector as a supplier of equipment for pad and screen printing, Pad Print UK is bringing its first digital print systems to market.

Something new is about to burst onto the UK printing market; something that will be of great interest to any company that prints flat and three dimensional components, and something that is applicable to a number of manufacturing and promotional gift companies or indeed any that is considering this as a potential new direction to move in.

Pad Print UK, a company with a 10-year background as an equipment supplier to the pad and screen printing market, is taking its first steps in digital print with two industrial UV-LED inkjet printing systems: the table-fed Digi-Jet PPT-5060-TL and the conveyor-fed Digi-Jet PPC- 5060-TCL. These are both designed for high speed print production.

The launch pad for these systems into the UK market is the page you are reading right now.

Duncan Hamilton, managing director at Pad Print UK, explained: ‘This is a new direction for us. For 10 years our core business has been pad and screen printing machines. We’ve been watching from the borders of digital print for a few years, waiting to get involved, waiting for the right machineto put our name to. The Digi-Jets are those machines.

‘At the moment we supply a lot of promotional printing companies, and this machine goes hand in hand with the equipment that they use. It is new technology for them, but it is complementary to what they already do.

‘But it also takes us into new markets, and we expect it to open a lot of avenues for us. It can definitely be of interest to commercial printers that are considering an extension of their business.’

As digital print technologies have developed in recent years, there has been a growing shift towards personalisation in the gift industry, while digital, with its quick and easy set-up, also makes short run printing possible. Pad and screen printing still have the high tooling and origination costs that made short run work unthinkable. Digital eradicates these costs and can also now print directly onto a wide range of substrates, from wood, glass and metal to PVC, foam board and acrylic. With the Digi-Jet systems you can print for example, 20 iPhone covers with 20 different images and 20 different names in one printing cycle.

These are not the first UV-LED inkjet systems to enter this market. There are alternative systems by other manufacturers that have similar pretensions. However, the Digi-Jets that Pad Print has secured for the UK market are robust, floor-standing systems, with larger print areas, individual print heads (six in total, CMYK +WW), and more importantly more speed.

The issue of printing speed leads neatly onto the real unique selling point of these devices: they can lay the ink down in both a uni-directional manner and bi-directional manner, which allows print speeds twice as fast as any comparable uni-directional systems.

This delivers productivity of up to 8.3 square metres per hour on both systems (1200 x 900 dpi).

Two of the Digi-Jets have already been sold in the UK ahead of launch, and in one case, a customer has reported completing what would have been a three day job on another system in just one day.

‘One of our customers is using it as a volume machine, running a large number of products through, because of the size of the bed and the bibi-directional capability. They were printing almost 2000 pens per hour, which is quick even by pad printing standards,’ said Mr Hamilton.

The impressive range of applications that the Digi-Jets can produce is augmented still further by them having two white inks in addition to CMYK, enabling them to print onto dark substrates, and to backprint on clear substrates.

As mentioned, there are two models available: a table-fed system (the PPT-5060-TL) with one litre ink tanks for each colour, a table size of 540 x 650 mm, and automatic media thickness detection, which can print on media up to 75 mm thick; and the conveyor-fed system (PPC-5060-TCL) with three litre ink tanks for each colour, a loading zone size of 500 x 600 mm, automatic media thickness detection, and capability to print on media up to 150 mm thick.

Pad Print UK has recently moved into new premises in Wellingborough, Northants, and has a sparkling new showroom to demonstrate its industrial digital inkjet systems in – it has been quite a 10th anniversary year so far.