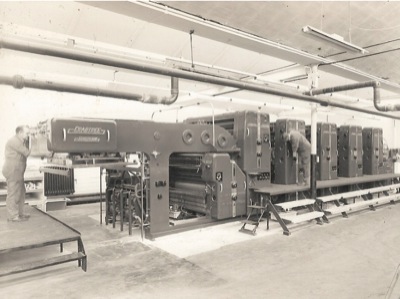

The Crabtree Sovereign Press – the first unitary offset press; these presses were still in use around the world in the 2000s

A slice of nostalgia, as Andy Tribute looks back at the great British manufacturers in the print industry that helped shape the industry as it is today.

In looking at this Best of British assessment of companies, I am going to look back at companies that no longer exist, ones that have been absorbed into other organisations, or ones where their business has fundamentally changed. In looking at the 50-year period that I have been in this industry there have been huge changes that fundamentally altered the operating environment for companies.

When I joined the industry in 1961, letterpress was the predominant printing process. Almost all type was set using hot metal machines, artwork was converted into copper or zinc printing blocks using large process cameras and chemical etching processes, and press make-readies took many hours rather than today’s minutes. Also there were no digital operations.

The first company I am going to cover is the group of companies owned by Vickers Ltd. This holding, which lasted from 1947 to 1966, combined the companies RW Crabtree, Dawson Payne & Eliott and George Mann. These companies date back a long time. Dawson Payne & Eliott started in 1849 and produced their first Wharfedale letterpress machine in 1859.

George Mann and Company was formed in 1871 and is known for producing the world’s first rotary offset press. RW Crabtree’s first press was in 1905. In 1909 Dawson Payne & Eliott introduced technology that had a major impact on changing the newspaper industry, particularly for smaller newspapers, with its two cylinder web-fed Cossar flatbed press. These presses were still being used when I started in the industry.

RW Crabtree, or Crabtree Vickers as it was known, however is the company that I knew best. The printing company I joined in 1964 was a major Crabtree offset press user. We had a battery of four Crabtree Countess A1 size two colour presses and we wanted more capacity. There were only two choices: either the new Crabtree Sovereign press range, or the German Roland Ultra presses. We chose to install two A0 format Crabtree Sovereign presses, a four-colour and a two-colour. Four colour presses were very new at this time.

These presses were one of the first unitary offset presses, which is now the only way presses are built. It was a decision we never regretted and the presses had both outstanding quality and performance. These presses were superbly engineered and I note that many of these presses were operating around the world well into the 2000s. Today, Crabtree is operating as an independent company, but it is now only in the metal decorating market where it is a market leader.

The Crabtree Sovereign press was really the forerunner of how almost all modern offset presses were built. It is worth pointing out that when this was first built, Heidelberg only manufactured letterpress presses.

Prepress

While offset printing technology has not fundamentally changed in the past fifty years, prepress has totally changed. In this area I could talk about companies like SR Littlejohn, the leading British manufacturer of process cameras, and a major alternative to market leader Klimsch from Germany. The company was acquired by Hunter Penrose in the early 1960s but closed down in the 1970s under the new challenge from the colour scanners. It is in the colour scanner area that my next company operated: Crosfield Electronics, founded in 1947 by the great genius John Crosfield.

From the mid-1960s, Crosfield and its major competitor, Rudolf Hell from Germany, totally changed the offset market and were instrumental in largely eliminating letterpress printing. Prior to introducing colour scanning, the company introduced the Autotron technology to manage register control of colour web presses.

Crosfield also introduced a range of other press control products including Secatron, Inkatron, Idotron, Viscomex, Insetter, Synchroscope and Insetter. Crosfield introduced its first colour scanner, the Scanatron, in early 1958. It then moved into drumbased scanners with the Diascan in 1965; in 1969 it introduced its Magnascan, which really set the standard for colour scanning for the future; then in 1976 it introduced the first digital colour scanner.

What colour scanning did was to automate the complex task of converting colour artwork or transparencies into film separations ready for plate making. It eliminated multiple camera steps and hours of manual colour retouching to correct limitations in the camera and film duplication processes.

In 1974, Crosfield was sold to De La Rue in order to fund the manufacturing of scanners to meet the massive growth in the market. Crosfield also moved into the colour workstation market in 1980 with its Studio product range, where it competed with Hell, Dainippon Screen and Scitex.

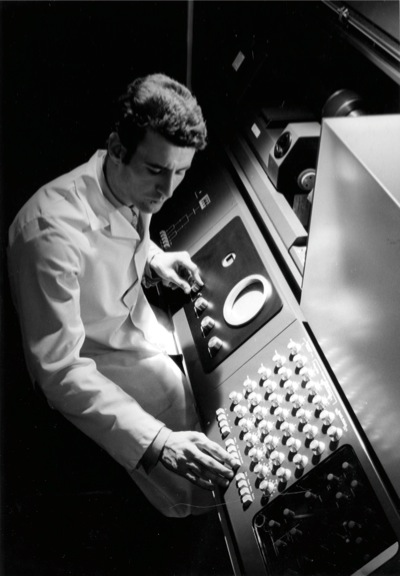

Crossfield’s Magnascan set th standard for colour scanning

Crossfield’s Magnascan set th standard for colour scanning

This was a massively profitable market throughout the 1980s. Crosfield made a profit of £21 million in 1988 on sales of £210 million. De La Rue, however, decided it was not a future business for them, and sold the company in 1989 to a joint venture of Fujifilm and DuPont for £235 million.

Either De La Rue was very lucky or could see that change was coming. The Apple Macintosh, Adobe Photoshop and desktop colour scanners, largely killed Crosfield’s colour workstation and scanning business in the early 1990s. DuPont later sold its share to Fujifilm and a later management buyout created FFEI, which today is a major player in computer to plate, specialised colour applications, and medical imaging.

Typesetting

The third area I want to cover is the typesetting market. Fifty years ago almost all typesetting was using hot metal with machines from Linotype, Intertype and Monotype. Phototypesetting was just starting. The largest UK typesetting supplier was Monotype, and it moved into phototypesetting with its Monophoto products. These were ideal for the highest quality markets like books, but were too slow and limited in functionality compared with foreign competitors from Merganthaler Linotype and Photon and later Compugraphic.

Phototypesetting was another technology that helped kill letterpress printing, and the output film or photo paper was ready for litho plate making without having to go through a camera process.

Monotype was not the only UK based manufacturer, and one of the most interesting newcomers was KS Paul, which introduced a revolutionary CRT based technology. Linotype took this on in the UK, creating Linotype Paul and the Linotron 505 typesetter.

This was an immediate success and was followed by the cheaper and faster Linotron 303, and then in 1978 the best product of all, the Linotron 202. These UK-designed and manufactured devices became the leading medium-speed phototypesetters worldwide during the 1970s and early 1980s.

Unfortunately, internal politics within the Mergenthaler Linotype organisation decided that it was inefficient to have manufacturing of phototypesetters in both Germany and the UK; the UK manufacturing facility was closed, and the Linotron products disappeared. At least a few of the key developers, in particular Linotype technical director Derek Kyte, set up Chelgraph and continued for some time to produce a range of new imaging products.

In 1977, Monotype made the next major change in phototypesetting, when it introduced the Lasercomp, the first device to set both text and images at the same time at full speed.

This laser-based device set the standard for all future typesetting and by the mid 1980s all suppliers had dropped CRT-based devices and hadadopted laser-based imagesetters. Monotype was predominantly successful in the newspaper market and sold well on a worldwide basis. However, it failed to keep up with progress and lost its position when computer to plate imaging took off.

Monotype no longer exists as a supplier of imaging products, but the Monotype Typography organisation is still one of the world leaders in the typographic market. Monotype Typography was sold to Agfa Corporation in 1998. In 2004, TA Associates, a Boston-based private equity firm, acquired the majority of Agfa Monotype’s assets. The company was newly incorporated as Monotype Imaging and its business focus returned to Monotype’s long-time expertise in type design.

Over the past fifty years many British suppliers have either closed down or been acquired. I hope that looking at key players in presses and prepress over that time will give readers an insight into some of the key developments from British companies that changed the printing industry around the world.

You missed the Crabtree 956S book printing machine + Crabtree 928S multi colour.