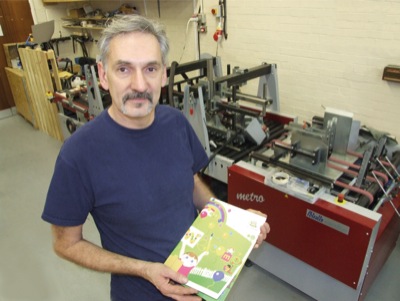

Andrew Lancaster, with Petratto behind

Hatfield’s Falkland Press is a company that hates to say no. So when a customer asked if it could handle an innovative packaging application, it pulled out all the stops to find the solution.

Digital packaging is very new for Falkland Press. In fact, when Digital Printer visits the Hatfield company, it has several piles of home-produced ‘silverboard’ stacked up close to its HP Indigo 5600 press, awaiting confirmation of only its second digital packaging order. The first order, consisting of two runs of DVD sleeves, each of 6500 copies, has recently been completed. The second order – a 50,000 run – is expected imminently.

For Jon Lancaster, managing director, that will make a fair degree of upfront investment worthwhile. He is not prepared to go into the finer details of Falkland’s development of its own silverboard stock (which is akin in many respects to Mirriboard, he said), but it was entered into so that the company could make best use of the HP Indigo press’s white ink option, and he reports that he has ‘just cracked it’.

He expects that one of the major paper merchants will be buying into the silverboard. While Falkland Press is a commercial print outfit, it has a niche in litho-printed packaging, and has built up an array of finishing capabilities to fulfil this, including die-cutting, foiling and laminating. Critical to the launch of its digital carton printing capability, however, has been its Petratto Metro gluer and box maker.

On the HP Indigo-printed DVD sleeves, this is applying glue to a simple glue flap. It can do much more, including enabling the company to produce more complex packaging designs such as crash lock bases. The DVD sleeves are also laminated using an Autobond system, adding lustre to the colours.

‘That’s integral,’ said Mr Lancaster. ‘You can’t be doing big runs like this by hand. We bought the Petratto five years ago. It’s a good machine but you need the right operator. We have the guy that used to install and train on them. It can glue in quite a variety of variations, including crash lock and straight line cartons.’

Alongside the white ink option, the HP Indigo press can also print on substrates up to 460 micron in thickness, and has HP’s One Shot technology, which accumulates all the colours on the blanket before transferring them to the substrate in a single pass, thereby ensuring perfect registration. This is particularly useful for plastics, which can stretch in the heat of production.

The press was not purchased to print cartons, but to add digital to the company’s commercial litho offering. However, a customer request got the company beavering away to find a solution, and the Indigo’s white ink was the answer. ‘You cannot print on foil with normal litho inks, and we’re not a UV printer,’ Mr Lancaster explained. ‘The white ink ability means we can start doing more specialist packaging. It’s not about short run. Our short run packaging will be runs of 500 and we will still use litho. The decision to use litho or digital will be based on the application: if it’s to print on a metallised surface or on plastic – things that we cannot do litho because we’re not a UV house – it will be digital.’

Being a digital process, wet proofing is a quick and cheap task of course, and he believes that the HP Indigo white ink provides a better result than UV, saying: ‘No-one can UV litho print as punchy colours as we can on the HP Indigo. With UV, there’s too much dotgain and the white is not so opaque. It’s perfectly opaque on the Indigo.’

He reports that the 13,000 DVD cases went ‘swimmingly’, and he’s looking to promote this new service. Anyone that requires packaging could potentially be a customer, if they are looking for high end cartons that can be produced with silver board and white ink. He is, he says, ‘keen on digital’, and backs that up by revealing that Falkland has placed an order for the new B2 HP Indigo 10000 press.

This should have benefits across the business, but digital carton printing certainly will gain from the larger sheet size. ‘We want to grow this as much as possible and we’re getting the Indigo 10000, which is a hungry machine. A lot of cartons need a B2 sheet, and certainly a B3 sheet, which we cannot get through an HP Indigo 5600. The 10000 gives us double the sheet size, so hopefully at 4-up and 6-up instead of 2-up it will be cheaper and faster.’