Kodak Prosper print modules fitted to the top of the CutStar unit on a Speedmaster at the Anton Group. Note the Adphos near infra-red unit for drying

Kodak has found a useful niche in hybrid printing, which combines the advantages of offset printing with the benefits of variable data. Nessan Cleary reports on its and other manufacturers progress.

We often talk of digital printing as if it was the opposite of conventional printing, but there is a noticeable trend towards combining the two for a hybrid solution. This has been done before, but mostly with low resolution print heads that limited the potential applications. In the last two years however we have seen a number of installations using Kodak’s Prosper imprint modules.

These units can match offset presses for both speed and image print quality, meaning that the variable data elements do not look out of place to the readers. These have been used for both direct mail and newspaper applications, bringing the added value of variable data to high volume offset printing.

Mostly they print on a narrow swathe so that the inkjet ink coverage is low, keeping the costs down, and allowing the customer to use their existing substrates. Kodak’s print modules use the same imaging and ink systems as in the Prosper press.

There are several options, all of which have a print swathe of 10.56 cm. The S5 runs at 152 metres per minute (mpm), with the S10 at 305mpm, both having 600 x 600 dpi resolution. The S20 achieves a faster speed at 600mpm but at the expense of resolution, which drops to 600 x 300 dpi. The S30 is faster still, at 900mpm, but the resolution drops further to 600 x 200 dpi. The slower modules can easily keep up with most sheetfed presses and are typically used in direct mail, while the faster heads can match the speed of a web offset press for newspaper applications.

Interestingly, all of the current Kodak hybrid installations have been led by customers opting to add these heads to their existing lines. One of the first UK customers to use the Kodak modules was CN Newsprint, part of the CN Group based in Carlisle. This is a monochrome set up with S10 modules mounted inline with a KBA Comet press, and is used for bingo cards and printing barcodes to inserts.

Guy Forrester, general manager, says that variable data gives CN Group an opportunity for further growth. In Germany, publisher Axel Springer started by adding Kodak S30 head to two of its Manroland Colorman newspaper presses. The inkjet system can keep up with the press at 914 metres per minute and is used to produce lottery tickets.

Earlier this year, Axel Springer ordered more print modules to be fitted to a mixture of Manroland and KBA presses giving it a total of 33 Prosper print modules. In Holland, the Thijsen Media Group (TMG) installed four S20 heads on a web offset press at its Emmen plant at the end of 2012, and is adding four more S20 heads on a second web offset press at its Buren plant this year.

TMG has said that this will allow it to produce high speed full colour variable content for advertising leaflets. Another option is to add the inkjet heads to a finishing line. This is the approach taken by the Lettershop Group in Leeds, which built a custom tower as part of a finishing line to house eight S10 heads for a colour duplex solution. The tower includes infrared dryers, which can be switched on for the whole web width, or just to dry a narrow swathe.

The heads are mounted on rails so that even though they only print a 106 mm swathe, they can be positioned anywhere across the 965 mm width of the printed web and can also be easily accessed for maintenance. Melter Mail Service, based in Mühlacker, near Stuttgart, has done something similar, installing eight S10 colour heads to a custom tower on a web finishing line in 2012.

Melter had already installed eight mono S10 heads in a finishing line for preprinted offset sheets in 2011. VPrint, a Belgian direct mail printer, has taken eight Kodak S5 heads for use with its finishing lines. The heads can be moved to different positions on the line, giving a great deal of flexibility in terms of which areas on the page are printed and whether or not colour or duplexing are needed.

Ryobi integrated an S5 head to one of its 750 offset presses at the request of a Japanese customer and now offers this as an option. Toshihiko Komatsu, chief executive of Komatsu General Printing Co, says that the press has dramatically improved the company’s personalisation capability, paving the way for future growth. Presstek also offers a hybrid option with an S5 module, but only on new presses as extra towers are added for the print modules and their associated drying units.

Alternative printheads

There are alternatives to the Kodak modules. Atlantic Zeiser makes a number of printhead modules, including the Delta 105, which can run at up to 300mpm with a resolution up to 600 dpi and a print width of 105 mm. It can be used with water-based and UV inks, the latter making it suitable for printing to difficult substrates such as plastics.

It is a piezo printhead, with five levels of greyscale and a fairly compact design so that it is easy to fit into existing lines. Both Manroland and KBA have partnered with Atlantic Zeiser to offer hybrid options for their presses. Manroland’s Inline inkjet module has the printheads fixed to a printbar that covers the width of a sheet.

It runs at 7000 sheets per hour at 600 dpi or 14,000 sheets per hour at 300 dpi. KBA makes hybrid versions of both its new Rapida 105 and the 106 sheetfed presses with an additional tower which houses two Delta 105i inkjet modules, though KBA says that customers can opt to fit up to eight of these inkjet units. Both offer monochrome solutions using UV-curable ink.

HP launched the C800 imprint modules at last year’s Drupa show

HP launched the C800 imprint modules at last year’s Drupa show

In both cases the resolution is said to be good enough for some variable data text, such as for printing lottery numbers, as well as barcodes and security marks. HP has two print modules – the C500 runs at 152mpm while the C800 runs at 244mpm. They print a 108 mm swathe and have a resolution of 600 x 300 dpi. Up to five of these head modules can be stitched together giving a 508 mm width. Each module contains four channels but only one of these is used for the mono version, which can thus easily be upgraded to colour.

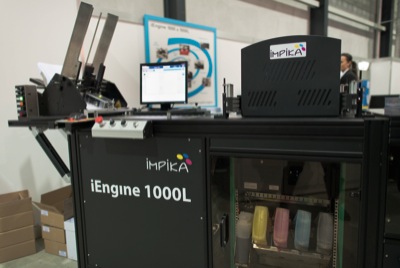

Impika sells the iEngine 1000, which uses Kyocera drop on demand piezo heads and works with a variety of inks, including water-based dye and pigment, MICR, UV or fluorescent. The standard iEngine 1000 prints at 108 mm wide at 600 x 600 dpi resolution, but with four levels of greyscale, which Impika claim gives it a visual look greater than 1000 dpi.

There is a choice of using one, two or four printheads for monochrome, dual colour or CMYK, at speeds from 75mpm at 600 x 600 dpi resolution up to a maximum of 600 mpm at 300 x 600 dpi in monochrome.

There is a larger 1000L model that has double the number of heads to print a 220 mm wide swathe. Meanwhile, Domino has developed the K600i, based around a Domino piezo head with a resolution of 600 dpi, and four levels of greyscale. It is supplied as a printbar, printing up to 782 mm wide. For now it is available as a single unit, with a speed of 75mpm, or as a dual unit, which runs at 150mpm, but Domino is working on a single unit version that will run at 150mpm that could be ready by the end of the year.

Despite all this activity and development, for now Kodak dominates this market. The competing print modules are being used mainly in mail inserters, and labelling or packaging applications. The press manufacturers have had only limited success in selling hybrid options on new presses. Instead this market has been driven entirely by customers looking to add value to their existing offset presses.