The demands of colour management and file preparation are not diminished between printing cartons conventionally and digitally. Prepress remains a key aspect of a carton board workflow.

There is one very obvious difference between prepress for conventional carton printing and for digital carton printing: there are no plates to make. That doesn’t make prepress a redundant stage however. There are plenty of other potential issues that can crop up, and even a hastily assembled list of potential prepress issues could include preflighting, colour management, file format standardisation, automated workflow, imposition and nesting, and proofing.

‘I would say that colour management and preflighting are the two big areas that companies need to look at,’ said Paul Bates, regional business manager for UK & Ireland at Esko. ‘There have been big issues with matching spot colours on digital. You mix the colours on screen, print it, tweak it and print it again. We have scientific ways where we can profile that colour. If it is in gamut for that digital machine, we can get within two delta Es every time. ‘With preflighting, that can be done by customer service staff immediately. Repro will only need to see it if there is a problem. And if there is a problem, the earlier you get a headsup, the better.’

Paul Bates, regional business manager for UK & Ireland at Esko

Paul Bates, regional business manager for UK & Ireland at Esko

PDF is the chosen format for packaging jobs today, just as it is in commercial print, and this degree of standardisation is certainly helpful in ensuring more files are print-ready when received. Andy Cook, managing director of FFEI, which recently introduced RealPro Toolkit software, aimed at labelling and packaging applications, points out that by their nature, many PDFs for packaging work are more complicated.

‘The whole challenge is much more complex in packaging, because there are so many different elements in the files, and the ability to filter out any problem elements is the first challenge – things like text size, or vignettes; if the printing process cannot print anything more than a 3% dot you need to flush those things out. In a high quality commercial print environment it’s more tolerant of these issues.’

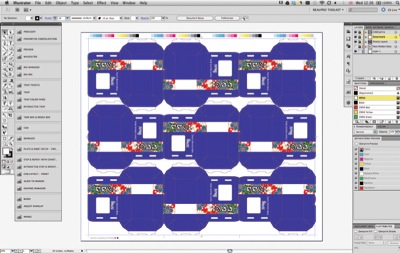

RealPro Toolkit consists of more than a dozen modules that address specific prepress workflow requirements, such as file editing and preparation, colour management, trapping and step and repeat. These are all plug-ins to Adobe Illustrator, which is commonly recognised as the most popular application for creating packaging files, said Mr Cook. ‘Many users face the same problems with proprietary file formats, PDF format conversion, lost layers, transparency issues – just to name a few.

RealPro Toolkit addresses this need for a complete solution inside Adobe Illustrator, providing packaging agencies with the power to make the prepress element of their workflow as easy to manage as possible, in a cost effective way.’ Starting at the end Esko has its own way of dealing with PDFs. It has a native PDF editing tool called Neo, and its own ‘flavour’ of PDF which uses XMP metadata that Esko workflow systems can automatically pull out – cutting profiles for example.

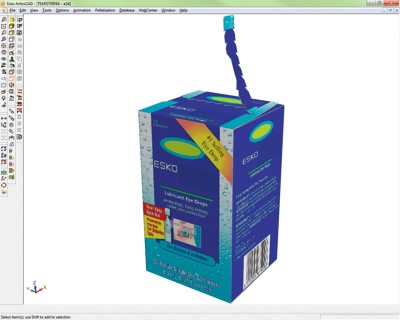

Visualising 3D packaging in design and prepress is an important process.

Visualising 3D packaging in design and prepress is an important process.

In fact, starting with the finishing in mind is very often a good idea for a digital carton prepress outfit. The reason for this is that packaging jobs tend to have less regular patterns and sizes than commercial print jobs, often with odd flaps and tabs included that are essential aspects of something that will become a 3D box, rather than a flat print. Therefore imposing jobs to make best use of the sheet and reduce the number of cuts required later can save much time. The nesting utility of most packaging prepress software is invaluable in this regard.

‘The way you nest is so dependent on finishing down the line, so it is understanding how you will cut that is going to be important for people moving into this area,’ said Mr Cook. ‘Highcon with its Euclid digital carton finisher is starting to disrupt that, but for today, you need to be thinking right up front how you are going to finish these things.’

Andy Cook, managing director of FFEI

Andy Cook, managing director of FFEI

There has been a tendency to view the digital press as a wet proofing or mock-up production system as well, but there are more cost effective alternatives to using a production press in these ways. Firstly, 3D viewing software such as FFEI’s RealVue and Esko’s Web Center allow customers to see how a pack will look in its finished form on screen, with simulated effects and lighting, without a physical dummy needing to be made.

If a hard copy proof is required, then an old fashioned remedy is still better than using a digital production press, said Paul Bates. ‘You can run off a one-off proof from a digital press but it is one expensive proofing machine. We can put in an Epson proofer and calibrate it to the digital press, colour managed to get it as close as possible to the actual result.’