Glossop Cartons’s Jackie Sidebottom with the Acuity 1600 LED

The proportion of packaging being printed digitally remains a fraction of the total, yet many see major growth in this area in the coming years. Press manufacturers have already responded to that optimistic prognosis.

Specialist packaging converting operators such as Belmont Packaging and Mercian Labels have already turned to digital printing technology to offer their customers new choices and take advantage of new approaches to managing the packaging supply chain.

The market has been dominated by offset, but digital’s special capabilities – cost effective short runs, fast turnaround, personalisation and versioning – are becoming of increasing interest to brand owners seeking shelf standout and a streamlined supply chain. The potential market size is also significant and likely to get much bigger.

This assertion is supported by research from Pira International which indicates that, while digital printing only represented 0.15% of the folding carton market in 2011, expected worldwide growth rates are more than 30% up to 2016. There is an opportunity therefore for enterprising digital print companies, even those who have not produced folding cartons before.

However, this is not always simply a case of putting some thicker board through an existing digital press. Most standard SRA3 digital presses are capable of printing on at least 300 gsm and more likely 350 gsm stocks, which is still somewhat lighter than the stated thickness of 600 microns that the new breed of carton board-capable HP Indigo and certain inkjet presses can print onto (the conversion between a substrate’s grammage and thickness involves multiplying by its density).

The sheetfed HP Indigo 30000 is being developed specifically for packaging applications. It is a close relation to the commercial print-focused HP Indigo 10000 B2 press that is already in beta in a couple of UK sites, but the 30000 press is designed for the folding carton industry, printing on any off the shelf substrate up to 600 microns, using the Indigo liquid electrophotography digital offset process.

HP Indigo 30000

HP Indigo 30000

It can print in up to seven colours (CMYK plus Orange, Violet and Green), with spot/Pantone colours simulated on press or pre-mixed off press. Print output speed is up to 3450 B2 sheets per hour, and an optional inline coater for UV and water-based varnishing can also be supplied. HP Indigo also provides a web press for packaging, the WS6600. HP’s digital front end is augmented with specialist packaging software from Esko in these cases, but it is not alone in that regard.

Xeikon’s 3000 Series presses are suitable for carton printing up to 350 gsm and provide format flexibility, with imaging widths up to 508 mm. Xeikon said several further aspects make the 3000 Series suitable for carton printing: its QA-I dry toner can be printed on any type of conventional substrate without pre-treatment, and provides a large colour gamut as well as good lightfastness; a new addition to the QA-I toner is Durable Clear Toner, which can act as a spot varnish or scratch-resistant protective layer; and true 1200 dpi quality makes it possible to print sharp details such as bar codes and micro text.

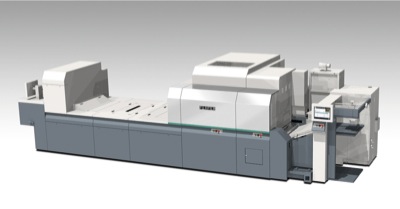

On the inkjet side, there are B2 format presses available from both Fujifilm and Screen that are both capable of handling 600 micron carton board. These are the Fuji Jet Press F and the Screen Truepress JetSX. Europe’s first user of the latter is RCS in Retford, which is printing personalised cartons on the press (see page 34 for more on this). The Jet Press F from Fujifilm runs at just under 3000 B2 impressions per hour and is similar to the water-based, commercially-focused Jet Press 720, except that it uses a water-based UV technology.

Fuji Jet Press F: an inkjet press for packaging

‘The idea is that you get all the benefits of a UV system, in addition to which you are able to reduce the pile height of the inks so you get a very smooth and even finish to the print, which follows the topography of the carton board,’ said Fujifilm’s Jon Harper Smith. ‘In terms of finished appearance, it will be similar to the appearance that printers currently get with offset, but we have a wider colour gamut.’ Xerox also claims to be a prospective player in the digital carton market, through its iGen4 technology, optimised for this kind of work.

Its Automated Packaging System includes a digital front end, a 350 gsm-capable iGen press, inline coater, stacking system and die-cutting unit (a standard Kama unit) which can handle effects such as bossing, foiling and braille. ‘That’s a very exciting piece of equipment for us, but the real power of that is when you start linking back into the workflow itself, to improve time to market and product life cycle,’ said Kevin O’Donnell of Xerox. ‘It has all the productivity and up time of an iGen, as well as colour matching with inline spectrophotometry.

High levels of consistency of colour are very important in the packaging world, where you can be complementing a run on an offset press, or doing the next series of a product range.’

Unfolding the issues

This is just one of several issues that commercial printers looking at digital carton printing need to consider – issues that touch on every part of the process, according to Eshchar Ben-Shitrit, HP Indigo’s Folding Carton go-to-market manager. ‘Printing cartons requires a certain degree of expertise that might pose some challenges,’ he said. ‘Many of the trade secrets of folding carton converters and printers lie not in printing, but in prepress and workflow.

When dealing with carton, your end product is not print, rather a box. Obvious as it might sound, making a box requires understanding of a different end to end approach. A suitable infrastructure needs to be in place – working with packaging graphics and 3D considerations, working with CAD based design for tooling.’

There is a heavy reliance on the use of PMS and spot colours in packaging, which are less common in the world of commercial printing, and brands will not comprise on their colours or on the print quality that they are accustomed to. Unlike brochures or calendars, the same cartons are usually displayed one next to the other, on a store shelf.

Colour consistency is therefore paramount. In cartons, the term short run usually still implies hundreds to thousands of units. This dictates the requirement for colour consistency along the run, which is less strict in the commercial market. Moreover, in cartons the majority of the jobs are re-prints, so colour consistency between jobs (and not just within the jobs) is very important. Reprints also require colour consistency between different print technologies, because repeated jobs could be printed using different presses.

Although many printed sheets can be easily converted to the finished box with simple cutting equipment and hand assembly, bulk production of cartons requires specialised converting equipment. ‘Most, if not all, commercial printers will have a flatbed die-cutter in house, but how many will have a fast folding-gluing line?’ asked Mr Ben-Shitrit. ‘High end printing of cartons usually involves spot varnish/foils/embossing/debossing, etc. At some point of the venture into cartons, an investment in additional finishing andembellishing equipment might be needed.’

Proof in the packaging

Further new printing technology is on the horizon, if distantly, including the Landa technology that has caused such a stir, and Océ/Canon’s Infinistream liquid toner press. It remains to be seen whether these manufacturers can deliver and when. Proofing and prototyping also needs to be considered and for this, entirely different technology is better suited.

Options might be Fujifilm’s 20 square metres per hour Acuity 1600 LED hybrid roll fed/flat sheet printer for short runs, and at a lower level Roland DG’s 4.5 square metres per hour VersaCAMM VS-series of printers and cutters, which has been paired with CGS’s ORIS Flex Pack software for just such proofing applications. Both of these systems have white ink options, so can be used for a wider variety of work, including on black substrates. Glossop Cartons saw the 1.6 metre wide Acuity at drupa and bought the machine ‘on the spot’, according to Fuji’s Jon Harper Smith.

They saw what we were doing on the stand, emulating exactly what they wanted to do in production using an offline Kongsberg cutter,’ he said. ‘With Acuity, three pieces of technology – our Dimatix print heads, LED technology and UV inks – have all come together to create something really quite special.

The really good thing for producing folding carton is the very bright colours you get from the UV inks, and one of the great features is the ability to spot varnish. It’s a very, very good effect – as good as very high quality screen printing. It was designed as a general purpose printer, but has found a bit of a niche in the packaging space.’ Digital carton printing is not without its challenges, but for those prepared to research and invest appropriately, this is an area of print that is rich in promise.

Fujifilm’s Jon Harper Smith

Fujifilm’s Jon Harper Smith