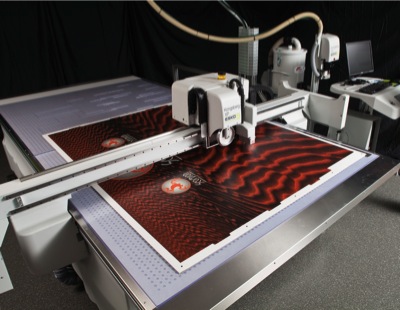

Esko Kongsberg XP24 cutting table

Digital printing of cartons may be the next big thing, but how are you going to cut and crease them? Simon Eccles examines current and coming options.

Ever since last year’s drupa show, digital printing of cartons has been tipped as the coming thing by industry pundits. They have been rather less eager to explain who needs it and for what purpose. Today’s retail and industrial carton printing is geared up for high volumes. There may be a so-far untapped scope for shorter runs as the press and finishing technology emerges to allow this, but it is a bit chicken-and-egg.

Probably it will happen though: five years ago nobody was sure if there was a market for short run labels, but once narrow web digital press equipment appeared, a new market developed. It may well be the same story for cartons, with digital press developers already putting a lot of money into this. However, printing is only part of the story.

Finishing, or conversion, is the key to folding cartons. Even more than commercial finishing, carton conversion carries an additional engineering challenge: folds and creases have to be designed with great precision, so the final box can be assembled and glued reliably, and stay structurally stable to protect the final contents. Conventional long run carton work uses tried and tested cutting and creasing dies assembled from metal rules set in plywood forms, often laser-cut.

Such dies are expensive to make and they have to be ordered well in advance of the job being first run. Full time carton printers will use dedicated autoplaten die-cutters, normally with automatic waste stripping. The latest machines can be changed and made ready in a matter of minutes. Once a die has been made, it can be stored and re-used over and over. If you have got the dies already made, it is not totally impractical to think in terms of short runs of a few hundreds or even tens if the price is right.

Smaller platens

John Harrison, who heads Friedheim UK’s Conversion Division, explains some of the factors to be considered. ‘Generally, the digital format is smaller, so commercial printers and carton printers in particular, found their size 6 and 3B die-cutters unsuited to the smaller format and very short runs. Many reverted to using ‘old style’ cylinder die-cutters. But, with printers running state-of-the-art CTP and the latest digital printing presses, the thought of relying on 50 year old die-cutting technology to finish the printed sheet has been far from appealing, both in commercial and image terms, and so a better solution had to be found.’

Friedheim is the UK distributor for Kama in Germany. ‘Early on the company recognised the likely future demand for a smaller format multi-application die-cutter, and at drupa 2008 Kama gave a world debut to the ProCut 53,’ Mr Harrison said. ‘This was the world’s first automatic flatbed die-cutter with a sheet format of 530 x 400 mm, and is also available with hot foil stamping.

Subsequently Kama has formed close working relationships with companies such as Xerox and Hewlett Packard as solution partners.’ At last year’s drupa, with press manufacturers announcing B2 digital carton machines, Kama followed suit with a B2 die-cutter to match, the ProCut 76. An important feature of both sizes is Auto-Register, which uses cameras to detect register marks and to adjust the position of every sheet.This is important for some digital presses where the printed image drifts from sheet to sheet.

Cut before you print

Yet even if you accept that platens and conventional dies are suited to relatively short runs, they are still not practical for very short runs and one-offs. The UK developer Creazy came up with a solution to this years ago. It produces a range of ready cut and creased blank sheets that can be run on digital presses without popping out of the sheet too early. Printers can buy boxes of blanks in advance and then only print what they need when orders come in.

Kama’s smaller Pro-Cut die-cutters feature camera registration to cope with digital drift.

Kama’s smaller Pro-Cut die-cutters feature camera registration to cope with digital drift.

There is a large choice of products, such as CD cases, tent cards, wine sleeves, gift boxes, golf ball boxes and so on. The main UK distributors are Premierbeswick, Antalis and Xeretec. Peterborough print finisher Print Solutions recently launched its own range of pre-cut products, called HeyPressGo. So far these are mainly presentation and mailing products such as tent cards and folders, rather than cartons. Creazy only offers products for SRA3 presses and has not said if it will move to B2.

However, as our story on RCS in this issue shows, it is possible to do it yourself: it has developed a range of pre-cut product sheets to go through its new Screen B2 inkjet press on-demand.

Highcon’s game changer

At drupa last year the Israeli start-up company Highcon showed a radically different take on carton finishing that it calls direct-to-pack. Its Euclid machine is a £560,000+ B1 format cutting and creasing machine. Euclid was the subject of a Digital Printer Centrefold inOctober 2012, so for full details you can refer back to that issue (or online at www.tinyurl.com/cm3b88f).

The essentials are that it uses high powered cutting lasers and a unique digitally image creasing rule system called DART (Digital Adhesive Rule Technology). Creasing rules taken from the CAD data are formed from extruded liquid polymer onto an impression cylinder, then hardened with UV light. The result is good for up to 10,000 impressions, but the image cannot be varied on the run and the rules cannot be re-used.

The B1 format Highcon Euclid at drupa 2012

The B1 format Highcon Euclid at drupa 2012

The laser cutters have no limits on run length of course and every cut can be different. As that story was being published in October 2012, Highcon appointed a UK distributor, Conversion-UK, set up by Mark Nixon, formerly UK sales director of press maker KBA, but with previous experience of prepress as UK sales manager of Scitex and Creo.

In January the first UK order for a Euclid was announced, from Glossop Cartons near Manchester (see box p38). He argues that the market for short run carton work is larger than many dedicated carton printers initially believe. ‘My opening gambit is always to ask: what is your average run length? They will usually say about 15,000, but then they’ll take another look and find it’s actually below 10,000. They tend to think in terms of hundreds of thousands, but actually those are only a fraction of jobs today. If you discount the 100,000+ jobs, then the average run might well be more like 6000. The Euclid is fine for these.’

Mr Nixon agrees that there may not be much demand for variable-shaped cutting jobs, but says that is not particularly important. ‘We think it will be used for composite jobs, where you put several small items to fill up the sheet and the combinations may be different every time. The combinations may be unique for each run, so there’s no need to re-use the dies.’ Since drupa the quality of the creases has improved a lot, he says, adding ‘drupa was probably about six months too early, but they had to show it.’

German laser

TheMediaHouse, a German printing company, has developed a laser cutting system called the MotionCutter, suitable for direct mail, carton and other finishing work. The price is £164,000 and the UK agent will be Pottersdown, which will sell through Perfect Bindery Solutions. Jörg Scheffler, managing director of TheMediaHouse, said that the project started four years ago to build a cutter for its own use, to complement its HP Indigo press. In particular it is used for personalised direct mail and business cards with names cut out, sold through the company’s web to print site, www.printmaileasy. de.

The first machine was built within 18 months and proved so successful that he decided to develop a version for commercial sale. It is a belt-fed machine taking sheets up to 60 cm wide (the nominal cutting format is 50 x 70 cm but it can go a bit wider for B2+ formats). Sheets are fed onto a mesh vacuum belt, travel under the laser and out the other side, where large waste falls into a bin and the finished items pass under a vacuum cleaner to pick up small debris.

The cutting speed of six metres per second determines the throughput, which can range from about 18,000 sheets per hour for simple cuts, down to about 500 for complex work. ‘Although originally built for the direct mail market, the laser cutter has been tested on packaging, personalised cards, one off and short run shapes, POS, etching, etc,’ said Shaun Stanley from Pottersdown. ‘It can also crease and perforate a sheet.

A computer graphic prediction of TheMediaHouse’s laser Motion Cutter

A computer graphic prediction of TheMediaHouse’s laser Motion Cutter

This means that the digital finishing process is streamlined further as the laser can cut out shapes, personalise, crease, perforate and trim.’ Unlike Highcon there is no physical creasing system, so fold lines are made by part-cutting though the board with the laser. Sample boxes made this way show sharp folds, though they may not be as strong as conventional creases where none of the thickness of the material is removed.

On the other hand, unlike the Highcon method, the folds can be fully variable for every sheet and the system is suited to one-off, on-demand work with no waiting time for creasing rules. The machine will be shown for the first time at the North Print & Pack show this month, with first deliveries expected by late June. ‘We will be showing examples of the laser’s work at North Print and running a video showing it in action,’ said Mr Stanley. ‘We cannot run the machine there due to the need for extraction on the unit. North Print will be the official UK and worldwide launch of the laser.’ LasX, an established US developer, also makes machines that perform laser cutting and creasing, but at higher cost than TheMediaHouse is planning.

Cutting tables

Digitally driven cutting tables have long been used in the carton sector for producing test samples of new designs. Some of the fastest models can be fitted with automatic feeders and unloaders and are used for short runs of large items, usually point of sale cutouts and dump bins made from corrugated board, or diebond and foamboard displays.

They could be used for cartons and the like, though suppliers we talked to said they cannot keep up with even the modest 800 or 1000 sheets per hour of today’s digital carton presses. Esko’s Norwegian subsidiary Kongsberg and Swiss Zünd are well known in this area, joined recently by DYSS from South Korea. Mimaki also makes several flatbed cutters as well as its better known roll fed vinyl cutters.

Paul Bates, regional business manager for Esko, said that Kongsberg XP tables with stack feeders are in use in a couple of UK corrugated boxmakers. Zünd’s latest G3 automated table offers similar corrugated handling features. For cartons, the primary use is still as sample makers.

Although Kongsberg claims to have the fastest table available, with a top head speed of 100 metres per minute, Mr Bates admits that is still not fast enough for carton production. ‘For now we can say if you’re printing digital, you can forget dies and buy a Kongsberg, but you’ll have to run it overnight, unattended. We’re working on a solution for cartons and there are developments afoot, but it’s probably two years away.’

AG/CAD, which develops the Kasemake packaging design software, became UK distributor for the DYSS family of tables in 2011. The X7 digital die-cutting system features automatic loading and a conveyor bed, plus camera registration.

The smallest model costs about £50,000 and takes sheets up to 1700 x 2800 mm, but there is no particular lower limit. Sales director Andrew Boulton said that it is mainly intended for corrugated and display board work. ‘The DYSS X7 is a solid production model that you could run 24/7. It’s tremendously fast for its type and it would be perfect for carton work, though not for thousands of sheets per hour.’