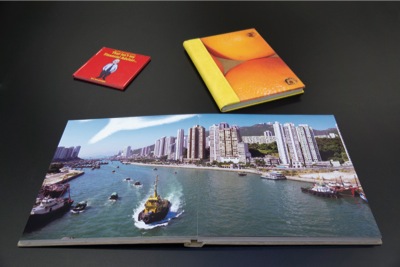

Sample of lay-flat books produced by Ashgate on the Fastbind FotoMount and Casematic systems. All sorts of formats are possible, plus unusual covers, the one at top right is Perspex

There is a wide range of options and equipment for making lay-flat books, an increasingly popular high margin offshoot of photobooks. Simon Eccles surveys what is available.

Photo books are already notable for high margins, but there is potential for even higher profits if you offer lay-flat books. These have pages with images that continue seamlessly across the fold and open completely flat, so the resulting spreads are displayed to best effect. Common applications are wedding and other special event albums, photobooks, top-notch company reports and proposals, creative agencies and photographer’s portfolios and pitches and promotional books for high value properties.

They can also be used with card inserts to make tough children’s books. Customers like lay-flat books because of the seamless appearance, the fact that they stay open on a table and because of the novelty. Service providers like lay-flat because it gives them another product to offer and because, as with many photo products, margins can be remarkably high. Details vary from system to system, but usually you print single-sided sheets for each spread in the book, then crease or fold them in half, printed side in.

The blank halves are glued back to back with a blank half of the next spread, and so on until a book block is formed. Card sheets can optionally be inserted between the sheets to bulk them up and stiffen them. The folds make up the book hinges. A suitably constructed hard or soft cover is attached, with hinges and gluing arranged so as not to constrict the block from opening flat.

It’s easy to get into lay-flat book production with a low cost, assistedmanual kit. Fully automated systems are available too, although the low-volume, often bespoke nature of this business means that only the largest operations are likely to need or justify the cost of full automation.

On the other hand, automated machines mostly allow the use of standard paper and lower cost hot or cold adhesives, where the manual systems tend to need special papers or adhesive sheets, so consumables cost more.

Books made using the Mazina Flexbind sheets open completely flat, but the image are not continuous across the fold

Books made using the Mazina Flexbind sheets open completely flat, but the image are not continuous across the fold

How it works

For one-offs, short runs and generally dipping your toe in the market, the various assisted manual systems do the job very well. The Fastbind products are big players in this market. They are made by Maping in Finland, with Ashgate Automation as the UK distributor that has worked hard to build them up in the UK market. Digital Printer has covered the Fastbind lay-flat systems in the past. In the February 2010 issue we produced a step-bystep photographic story that followed a lay-flat book being made by Lewis Price, Fastbind product manager at Ashgate.

The Fastbind range is more or less the same today. For lay-flat blocks, it offers the FotoMount assembly table. After printing, sheets are folded and placed in the FotoMount. Double-sided peel-off self-adhesive interleaf sheets (and cards if needed) are placed between the blank sides and smoothed down, with the FotoMount providing adjustable guides and a powered rising clamp to hold them together. After assembly the pages are trimmed in a guillotine.

On Demand Machinery’s Sidewinder assembles book blocks printed on Mohawk Panoramic pressure-sensitive paper

On Demand Machinery’s Sidewinder assembles book blocks printed on Mohawk Panoramic pressure-sensitive paper

If hard covers are needed, Ashgate can supply the Fastbind Casematic table for making custom sized hard covers from greyboards and printed self-adhesive cover sheets. Padded greyboards can now be supplied too. Blocks can be cased-in using self-adhesive end sheets, with or without endpapers. Prices depend on the size, with FotoMount ranging from £1990 for the 304 x 304 mm all-manual F32, to £3990 for the 457 x 457 mm F46e with electric operation and a foot switch.

Casematics are available for cover sizes from 330 x 330 mm (for £1495) up to the 450 x 450 mm (from £3990). New from Ashgate is the £345 RolaPress, a handy 500 x 700 mm fold flattening table with heavy rubber covered wheel on a sliding mount. You run this by hand over the folded edge of single or stacked sheets, flattening them and sharpening the crease. Transeo Media, best known for its Taopix online photo product ordering software, is also distributor for Mazina Flexbind, a lay-flat photobook system from the US company Holmberg.

Flexbind paper incorporates a hinge along one edge, together with an edge stiffener that stops it flipping prematurely in the press. There’s a choice of Matte, Dull, Satin, Felt, Photo Lustre, and Pearl finishes, suitable for toner or HP Indigo digital presses. Sheets up to A3 are available, with hinges on the long or short edges. Unlike other lay-flat systems, spreads are not continuous across the spine.

On the other hand, the sheets can be printed on both sides and finishing is much simpler than the back-to-back gluing methods. All you need do is trim the sheets (removing the edge stiffeners), then use a wire stitcher or thread sewer on the side of the spine area. Other types of binding are possible, including UniBind glued steel spines, Fastbind perfect binding, and other binding methods with EVA or PUR adhesives.

Mohawk cohesive

An alternative system is Mohawk Panoramic, distributed in the UK by Premier Paper. Here the digitally printable sheets are coated on one side with a pressure-activated glue from Convertible Solutions that it calls a ‘cohesive.’ This is not sticky with normal handling or press printing, as it requires very high pressure to activate.

It can be used in most digital toner presses plus HP Indigo presses. There is a choice of gloss, silk, smooth uncoated and recycled uncoated finishes, plus self-adhesive plain endpapers. The standard sheet size is 460 x 320 mm. Compared with self-adhesive, there is a lot of scope for adjustment while you are positioning the sheets manually, with less risk of trapped air.

Perfect Bindery Solutions (PBS) sells the Mohawk Panoramic hardware, which includes a book block assembly unit that combines a crease flattening roller and frame that takes removable positioning jigs. However, you can probably get by with just the jigs, which are sold separately. Ater block assembly the jigs are placed in a hydraulic press to activate the cohesive. PBS sells an Atom press for about £5500, which can also be used for die-cutting or embossing.

Automated production

PBS is also the UK agent for the US On Demand Machinery (ODM) range. At drupa last year ODM launched the Sidewinder machine to automate the Mohawk Panoramic block assemble process, from flat sheets through blocks ready for pressing. This costs around £66,000. It can make blocks up to 343 x 368 mm open and 685 x 368 mm closed (and up to 38 mm thick).

ODM also offers a pair of assisted-manual casemaking lines to assemble printed cover papers to cover boards and liners, one for covers up to 457 x 762 mm when open and the other ‘XXL’ model for up to 558 x 1187 mm. It also offers two sizes of Sticker semi-auto casing-in machines to assemble blocks into the cases, plus Super Sticker, a fully automated casing-in machine for between 400 and 600 books per hour.

Introduced at drupa, the Kisun Digi Binder DB-440 takes pre-folded plain paper sheets and assembles them using water based glue

Introduced at drupa, the Kisun Digi Binder DB-440 takes pre-folded plain paper sheets and assembles them using water based glue

Smasher is a press that forms the joint hinges on the cased-in covers. Smasher can be used as a press for Mohawk blocks, though PBS’ managing director Steve Giddins reports that this is slower than a dedicated press such as the Atom. Swiss company Photobook Technology makes automated lay-flat book assembly products, which have been distributed in the UK by IFS for the past year.

Mitamax is the compact core machine, which takes sets of single-sided printed and folded sheets (and optional card interleaves), applies a cold adhesive to the blank halves and presses them together to form a block. End papers are applied in the same run. Mitamax runs at up to 70 sections per minute on signatures up to 380 x 330 mm. After assembly it is recommended that blocks are pressed. Photobook Technology also makes the Mitafold creasing and folding machine and the Mitabook hard cover casing-in line for up to nine books per minute, which can be used with Mitamax if required.

Since last year’s drupa, Encore Machinery has been UK distributor for the Samed Innovazioni Photofast machine for lay-flat book gluing of books up to 480 x 400 mm. There are two feeders, one for the printed sheets and one for backing boards. Prices start at around £39,000 for a cold gluing model, with a hot gluing option costing a little more.

Hot gluing is more versatile, points out Mike Biggs at Encore, especially if you need to assemble resin coated photo papers without a board insert. ‘It also dries instantly with no need for pressing,’ he said. Tarrant Machines is selling the Korean made Kisun Digi Binder DB-440 lay-flat book assembler, first shown at drupa last year. It costs around £60,000, according to managing director Richard Tarrant.

CMC Italia’s M-Flat is a low cost assembly and clamping machine

CMC Italia’s M-Flat is a low cost assembly and clamping machine

This is a compact machine that accepts sets of pre-creased and folded sheets (plus wraparound cover sheets in the appropriate place), applies water-based glue to the blank sides, then assembles and presses them together to form blocks. A separate feeder takes cover boards which are fed and glued at each end of the block, and then the wraparound cover is glued to those.

A separate unit folds over and glues the edges of the covers. Optionally, card sheets can be inserted between the papers to bulk up the books. The DB-440 can handle up to 100 signatures (ie folded sheets) per minute, though the normal speed is up to 60. Blocks can be made from 3 to 60 mm thick and up to 360 x 380 mm in size. ‘When you make a lay-flat book block in the Kisun they also need a bit of a squeeze. We have a double-acting press to do this,’ said Mr Tarrant.

For higher throughputs, Tarrant is working with Imaging Solutions in Switzerland, though so far this company has sold directly in the UK, mainly to photolabs. It is systems cost from £300,000 to £400,000 depending on configuration. The fastBlock machine can produce up to 100 blocks per hour.

It performs a full sequence, taking printed flat sheets or rolls and then cutting, creasing, folding, pressing and gluing them to make finished blocks. Hot melt adhesive is used, which is both fast and suitable for resin coated photographic papers as well as digitally printing.

Also from CMC Italia, this QCoer 2 is for making hard covers with wraparound printed sheets

Also from CMC Italia, this QCoer 2 is for making hard covers with wraparound printed sheets

Alternatively, the fastBook-03 machine can be fed with pre-folded sheets, and assembles and glues them, again with hotmelt. This runs at up to 80 blocks per hour (assuming 40 pages per block). Tarrant is also agent for the CMC-Italia range of book binding machines, which includes M-Flat, a manually loaded machine for assembling and pressing self-adhesive lay-flat papers to form blocks. It costs around £5000.

The company also sells the Q-Cover series of machines for forming hard cases and then casing-in to the blocks. There are four models, ranging from short to medium throughputs by turning-in and gluing the cover papers on one, two or four edges per operation. Q-Cover2 (for two edges) costs around £33,000, for example. The Q-Case case maker is about £20,000 and the Q-Finish is £19,000.

Conclusion

Even more than conventionally bound photo books, lay-flat continuous spread books are niche products, normally destined for low volumes. However, their unusual, high quality appearance makes them even more attractive in this sector of the market, where customers are willing to pay high prices. Larger format lay-flat books with hard covers can sell for £50, £100, £200 each, representing a very high margin over the materials, costs of printing and labour needed for the semi-manual systems. Minimal outlay, maximum profit. What’s not to like?

Printing for lay-flat books

You can make lay-flat books out of any printed paper. However, the short run or one-off nature of the books means that either digital printing or photographic reproduction will usually make most economic sense. The majority of installed digital production presses are sheetfed SRA3+ formats, so the maximum width of an opened lay-flat book is going to be roughly 430 mm after trimming (Mazina papers are an exception).

That will suit many customers, but those wanting landscape formats and panoramas might want something wider. One answer is a wide format aqueous inkjet. For an outlay of a few thousand you will get a model that can handle any roll or sheet size you will ever need, on a very wide range of papers. However, they are fairly slow and their ink and paper costs are high. Larger format sheet fed digital production presses are now reaching the market. Kodak, MGI and Xerox all offer ‘long sheet’ versions of their roughly nominally SRA3 presses.

The Xerox iGen4 EXP can take sheets up to 364 x 660 mm, while the Kodak NexPress SX models were extended at drupa to take up to 356 x 914 mm. MGI’s Meteor DP7800 XL costs less than the Kodak or Xerox presses and takes even longer 330 x 1020 mm sheets (this is an option; standard models take up to 330 x 650 mm). Then there are the new breed of B2 sheetfed presses, which will give maximum lay-flat widths of around 700 mm.

Fujifilm and Screen are delivering production B2 inkjets (both chasing the photo book market), and HP has Betas of its B2 Indigo 10000 in already. Delphax and MGI will deliver similar formats this year. Xeikon can print virtually unlimited lengths on its 300 and 500 mm roll fed toner presses. LumeJet, which is developing a roll fed digital printer for photographic paper, would also be suitable. At the ultra-low cost end of the market, OKI’s nominally A3+ format printers have bypass feed slots and flat print paths that allow them to take sheets up to 328 x 1200 mm.