See also: drupa part 1: digital presses and drupa part 2: software

Evident at drupa was how much the demands of digital printing are now influencing finishing developers, and not just the small format short end of the market. By Simon Eccles.

Autobond said the show was a big success and which returned to its Derbyshire factory with full order books sufficient for six months production. Among five new laminating, encapsulating and spot UV machines was the Micro 52 SD TP, an entry-level but heavy duty B2 thermal laminator aimed at the short run, multi-colour B2 and B3 markets, with quick make-ready and a ‘tiny footprint’ of 2 x 1 metres.

Also new were the Mini 76 SD ‘Multi’ and Mini 105 TPHS thermal laminators. Its SUV (spot UV) range was extended with a standalone 52 cm wide machine (to run nearline with double-sided laminators), while the company announced it is developing a 74 cm inline version for the end of this year.

Baekert introduced customisable coloured wire for spiral binding. This new polymer coated wire can be produced with any colour, giving a design touch to make the finished product easily recognisable and more distinctive.

Bell and Howell demonstrated a full Automated Document Factory for mailpiece production and insertion. This was controlled by the IQ Software suite, whose modular architecture can control virtually anything. Modules are available as local software or as a hosted service.

The Ascender 14 inserter was demonstrated with the company’s Harmonix throughput management software and Navigator user interface, said to increase operator productivity dramatically. It also showed its JETVision solution for data integrity and quality control checking on mailing lines. Bell and Howell is now distributing and supporting Neopost’s folding and inserting technologies, as part of its new Sprinter series mailing solutions.

Bielomatik introduced a new Compact Folio Sheeter, CFS 105, to take paper rolls and cut them to sheets using a new cross-cutter. It’s especially intended for sheetfed digital presses and has features to avoid marking on fine and sensitive paper through to board and foil. The maximum cutting length is 1200 mm with web widths 1050 mm.

The fully automatic P-35-49-Plus, the company’s flagship in automatic spiral and wire comb binding, has a two-up binding drum to boost speed by 33%. A new cartridge system for the punching and cutting unit, plus electronic setting of cut-off lengths and sheet counts, cuts size change times almost in half. This can also be fitted with a register unit to allow offline sheeting from a web press.

P-24-90 is a new machine dedicated to exercise book production, with simple operation and maintenance.

Bobst published the results of a survey into digital printing for packaging. Emilio Corti, head of sheet fed sales, said: ‘We have now committed ourselves to presenting our first industrialised digital concept machine at an open house that we will hold in the second half of next year. This won’t just include digital printing equipment but will also address digital post-press.’

New systems were introduced for Bobst’s folder-gluers, including Speedwave GT, which improves the on-machine performance of complex cartons such as crash-locks, in-line Braille embossing and Accucheck which inspects for print and substrate defects.

CP Bourg had its own stand but also supported other manufacturers around the show, notably Xerox. New at the show was an enhanced dual-mode BSF Sheet Feeder (called BSFEx) that allows CP Bourg finishing equipment connected in-line to a Xerox iGen or Nuvera press to also act as a nearline finisher for other presses. It can accept printed stacks on carts from high-capacity stackers on Xerox, Canon, HP Indigo, Kodak and Océ presses, plus others. It’s pictured here inline to a Xerox iGen4.

New Stack Carts have air tables to aid the transfer of print from digital presses to any nearline BSF-based binding and finishing system.

Three new perfect binding systems were announced: the Bourg BB3202 ‘next generation’ fully automated system for inline use; BB3102, an automated offline binder for short run and on-demand work with optional unattended loading via the BBL Book Loader; and BB3002 PUR, a compact PUR binder for on-demand work.

The Buhrs 5000 paper wrapping system launched at drupa can process up to 30,000 products per hour. It’s intended for bulk volume direct mail, transactional mail and transpromo items. Optional inkjet stations can produce addresses or full colour messages, allowing the system to replace conventional envelopes. Alternatively it can produce self-mailers with inserts. Friedheim is the UK distributor.

Duplo showed enhancements to its recently introduced DC-745 Production Colour Finisher, the high speed model in its family of compact modular finishers. New at the show were strike perforation (for tear-out coupons and tickets), embossing and die-cutting, as well as the Integrated Folding System for complete single pass production of folded leaflets, greetings cards and mailing pieces. A ‘technical demonstration’ was shown of embossing using male and female steel dies.

The new DBMi Saddle System, announced in February (and pictured above), is intended for both digital and offset work on book thicknesses up to 120 pages, with 60 second makereadies. There were four on the stand.

A new DSF 2200 sheet feeder can be used with a variety of Duplo finishing kit, such as the DBMi. It replaces the DSF2000, and is faster with a revised bar code reader for setting up the finisher.

The new FKS PrintBind KB-4000PUR is a single clamp on-demand perfect binder that applies both PUR and EVA hotmelt glues. PUR goes down the spine of the book for strength and durability. The book block is side glued using quick drying hotmelt glue, so the operator can handle the book almost immediately.

Esko’s Digital Finishing solutions centred on four of its Kongsberg digital finishing tables, including the new XN, described as ‘a highly versatile and productive digital finishing table that can be configured easily for the widest range of different applications.’

Heidelberg introduced the new Stitchmaster ST 500 saddle-stitcher, saying its individual drive technology, centralised control system, and wide range of feeder models make it suitable for rapid, all-purpose work. It runs at up to 13,000 cycles per hour. It can collate stack-signature brochures in preparation for adhesive binding, said to be a first. New options such as the third step in the trimmer allow products to be created with added value that would previously have needed two passes.

The Stahlfolder TI 52 and TI 36 buckle folders gained a new CCT machine control system, said to make them far more user friendly while significantly reducing makereadies. They are for small format work but with 14 and 16 buckle plates respectively they can handle a wide range of folds, including complex fold-gluing and gatefolds.

Highcon is an Israeli startup company that introduced Euclid, a ‘direct to pack’ all-digital cutting and creasing machine for sheets up to B1 format. This drew crowds at drupa whenever it was demonstrated. It cuts by laser but creates creasing dies internally from extruded polymer. For more details see Digital Printer September 2012 pages 32-33.

Horizon introduced a wealth of new kit, as usual. It also appeared on six partner stands as well as its own, showing 28 different systems. One was a new flexible perfect binding system for both offset and digital print output. It combines the AF-566F digital + PSX-56 folding and stack output system with an interface conveyor to the CABS4000S perfect binding system.

The HOF-400 digital sheet feeder allows flexible-configuration book production from digital print. It handles 42000 sheets per hour with A4 short edge feeding. It can be connected with the SPF-200A and StitchLiner5500 systems.

The CRF-362 creaser and folder handles digital print without cracking, including a wide range of light to heavyweight and cover stocks, coated or uncoated.

On-demand perfect bound book production from rolls is possible with the Smart Book Solution, comprising the AF-566F Digital + PSX-56/ BQ-470 for folding, perfect binding and three knife trimming.

An ‘all-in-one’ offline bookletmaker for digital finishing can be formed by combining the SF-100 + CW-8000NL systems for bleed trimming, creasing, stitching, folding, face trimming and stacking. A printed mark reader lets it create booklets with varying page counts.

The existing SPF-200A booklet making system now has A4 landscape capability. An HOF-400 digital feeder can be connected for digital print production. HT-1000V is a new variable trimmer that aids on-off book production. It can be used as part of the Smart Binding Solution together with the AF-566F Digital folder + PSX-56 / BQ-470 perfect binder to form a compact on-demand book line.

Hunkeler had several new products at the show, but the most unusual was a laser based perforation system, called HL6. It uses a laser to put perforations anywhere you want them on a 520 mm web. This was described as a ‘technology study.’ It grabbed a lot of interest so it’s a safe bet that you’ll be able to buy one eventually. There are two models: the HL6-I that operates between 50 and 75 metres per minute depending on complexity (seen on the drupa stand, pic below); and the more powerful HL6-II that runs everything at 150 metres per minute.

It can produce dynamic conventional tear-off perforations or file punch holes in different positions on every copy, but it can also be used for security applications such as replicating printed cheque numbers or even signatures (shown below) – something that would be hard to counterfeit. The laser power can also be wound down so it only scores the paper without punching through, though there is some yellowing.

More conventionally the company introduced the DP6 ‘highly dynamic’ perforation module, which can change patterns from copy to copy. In addition to longitudinal and cross perforation, dynamic file hole punching or form punching are also possible.

Hunkeler cheerfully described its new Book On Demand Solution as competing with the equivalent Muller Martini SigmaLine configuration at about half the price. It produces book blocks with 4, 6 or 8-page signatures in non-stop operation at up to 200 metres per minute. The drupa machine was running offline but the real thing can run inline with a digital web press.

A new large format roll to sheet system combined the UW7 unwinding module with a CS7 cross and longitudinal cutting module and LS7 large format stacker. This creates sheet stacks up to 1100 x 760 mm and up to 800 mm high.

The new Primer Coater Module PC7 for large web formats can be used either for pre-coating of a primer before printing (for inkjet web presses for instance), or post-print coating.

UK digital finishing system maker IBIS Integrated Bindery Systems introduced its Smart-binder PLUS, a 30% faster version of its original Smart-binder, which can combine saddle-stitching with a unique glue binding system in the same line. See Finishing Line, page 62-63 for full details.

Kama CEO Marcs Trelau shows a sample from the ProCut 76, behind him.

Kama launched the ProCut 76, which it said was the world’s first 760 x 600 mm format diecutter with integrated hot foil stamping. It includes a universal chase for all sizes of dies. It can be used for cutting, creasing, perforating and kiss-cutting, as well as blind embossing, Braille stamping, hot foil stamping, relief and hologram stamping. Changing from diecutting to foiling takes less than ten minutes.

Camera based AutoRegister was introduced as a new option for the ProCut 53 and new 76 machines. Registration is adjusted by a pair of servo motors in the x-y directions. This is particularly relevant to digital print, which has a tendency for the image to drift on the sheet. Kama is distributed by Friedheim in the UK.

Kern unveiled what it claims is the world’s fasted mail inserter, the Ai-33, capable of handling up to 33,000 items per hour. It’s the fastest member of the Ai family, which have what Kern calls ‘a new level of embedded intelligence.’

Also shown for the first time was the Kern 130 / 141 high performance rotary cutting line. It’s a roll to cut and stack solution in a small footprint. There are pinless or pinfeed options, as well as high stack capacity. The system is suited to transactional, transpromo, direct mail and book-making.

Korean finishing systems manufacturer Kisun showed a new version of its compact DigiBinder that can assemble layflat books (for pages glued back to back to open flat). This can assemble paper to paper using water based adhesive, or can add a board sandwich to increase bulk. It can assemble books from 350 x 305 mm down to 120 x 165 mm, at around 60 signatures per minute. Encore Machinery is the UK distributor for Kisun.

Linked to the Timsons stand at Drupa, Kolbus fitted a SF832 sequential signature feeder and KM200 perfect binder system inline to the very high throughput Timsons T-Press to produce completed books during four demonstration runs every day. It was also demonstrated for nearline running, which is probably a more likely commercial configuration. Book thicknesses could be varied on the run with zero makeready at any stage. A complete print to finished book line is called Bookjet by Kolbus.

A nearline configuration could also be modified for colour photobooks by adding an XHB 500 sequential single-sheet feeder: one of these has gone to a German photo specialist, running with HP Indigo output.

Also shown was the new KM 600 perfect binder, intended as an affordable entry into the Kolbus range. The standard version runs at 4200 to 7000 cycles per hour but the KM 600.C can go up to 9000 cycles. 600.C was demonstrated as part of a complete line with an 822.C gathering machine and HD 153.M three-knife trimmer.

The company claims its BF 530 is the world’s fastest book finishing line, completing 70 books per minute. Highlights include sectional make-ready for digitally printed hardcover products and casemaking with varying spine widths.

It also announced an automatic high quality packaging line for the likes of jewellery or luxury cosmetics, drawing on its casemaking expertise. These are for heavy duty boxes, rather than conventional cartons. It demonstrated a line formed from a DA 260 automated casemaker linked inline with an SA 260 lining machine, and was giving away boxes for corkscrews and soap.

Kugler-Womako caught a lot of people’s attention with its new EcoBinder system, which produces all-paper bound documents without glue or staples. Recycling is easy. It holds the multipage document together with wide strips of 250 g/m2 paper inserted through slots and hotmelt glued to form wide flat rings. These can be pre-printed to form an additional promotional area. Materials costs are said to be half those of wire or plastic binding, but the machine isn’t cheap.

Lasercomb introduced a new generation of its ProDigi multi-functional plotting table for packaging work, the ProDigi NEO, which can operate at up to 100 metres per minute. Three versions are available for formats of 800 x 1300 mm, 1600 x 1300 mm and 2100 x 1300 mm.

A new front end PC featuring a colour touch screen allows the operator to choose between automatic or manual modes, as well as accessing the tool database. Three tangentially controlled tool holders can handle up to seven different tools with quick changeover. Alternative tools include cutting/creasing/drawing units and a 3D milling unit. A conveyor is optional. No compressed air means near-silent operation, making it office-friendly. Freidheim is the UK distributor.

Mathias Bäuerle (MB) introduced the prestigeFold NET 66 fully automatic folder, a larger development of the existing 52 machine that can now handle sheets up to 660 x 1320 mm at up to 220 metres per minute. This allows more formats, such as 3-up A4 products or 24 page A4 signatures. It can be configured to run inline to cut sheet or continuous digital presses (via Tecnau or similar cutters if needed) or as a nearline system with a sheet feeder.

At the show a prestigeFOLD NET 38 was equipped with a special fold unit for producing pharmaceutical package inserts.

Since drupa MB has had to flle for insolvency and is trading in administration, but as we went to press it was still saying it is seeking new investors. The UK distributor is Encore Machinery.

New on the MBO stand was the K8 Perfection, a new combi folding machine for sheets up to 700 x 1000 mm. It’s 12% faster, easier to use and more efficient than its predecessor, says the company. The three standard configurations can be further customised with selective automation. Top speed is now 235 metres per minute. New knife units can run up to 40,000 cycles per hour with less wear and failsafe operations. Friedheim is the UK distributor.

Meccanotecnica showed a new Universe Digitaline concept with two book production lines based on its Universe Sewing machine, which can process both digitally printed flat sheets and conventional signatures.

The first line showed the Universe sewer connected to an inline Universe Binder and Three Knife Trimmer. The second was aimed at book block production, linking the Universe sewer to an inline book block press, end-papering unit and leading onto book gluing and lining.

MGI unveiled the next generation of its JETvarnish inkjet based spot UV varnisher, due to ship this autumn. The new JETvarnish 3D is not only three times faster than the original (now up to 3000 sheets per hour), but can build up raised images to simulate embossing, somewhat like the Scodix system. The raised image can be up to ** microns and textured effects can be generated.

It handles sheet formats from A3 up to 520 x 1050 mm, in weights from 135 to 500 g/m2. It can handle variable data and can register to pre-printed sheets.

Mohr is a new brand from Polar, aimed at the print on demand digital finishing market. Polar-Mohr’s long standing relationship with Heidelberg as its international distributor is continuing unchanged. Mohr branded products will be distributed in the UK by Watkiss Automation.

The initial models are all guillotines: the Mohr 56, 66 and 80, in entry level Eco and more advanced Net (networkable) versions.

Morgana showed its current range of finishing systems, many of which are suited to digital, but said it was planning to announce new models later this year. It did have a pair of new DigiCoater coaters on its stand.

The DigiCoater 33 is an entry level model for digital and offset sheets up to SRA3 formats. It is supplied with three tanks and one coating roller, and can quickly be changed between gloss, matt and textured finishes. DigiCoater 50 is for larger sheets up to 500 mm wide. There are two versions. One has four tanks and two rollers and is for coating only. The other has six tanks and three rollers and can be used for priming sheets prior to printing.

Also new were two PUR binders from Italy, joining the original DigiBook 300, which binds 300 books per hour. The new models are the 150 and the 450, for 150 and 450 books per hour respectively.

Morgana announced that it would be selling the Uchida Aero cut Quatro multi-functional modular finisher (see Digital Printer July).

Muller Martini showed the latest version of its established Sigmaline book line for inline operation with fast digital presses (a speed compensating buffer conveyor is pictured above). This was first seen as a prototype at drupa 2004. New for the show was the digital-ready Alegro perfect binding machine, which gained orders. This includes stations with separate drives for individual control and can handle formats from ultra-small sizes up to A3.

Muller Martini systems were also demonstrated on the stands of HP (producing books inline with a T400 inkjet web press) and KBA (a Sigmaline comprising a SigmaFolder and the Primera Digital inline with the new RotaJet inkjet web press to fold and saddle-stitch magazines and advertising brochures).

American book binding manufacturer On Demand Machinery introduced Sidewinder, a system for open-flat on-demand books designed for use with Mohawk Fine Papers’ Panoramic range of papers. The paper has a photo printing surface on one side and ‘cohesive’ pressure-sensitive adhesive on the other. When the sheets are folded and mounted back to back, the book opens completely flat across the fold. Sidewinder automates the whole process, combining scoring, folding and pressing to create book blocks up to 40 mm thick with a maximum open size of 675 x 362.5 mm.

Also new was the Super Sewer XXL, a large format book sewer for formats up to 457 x 457 mm operating at up to 400 per hour. It’s mainly intended for large format photobook production.

At drupa the Italian manufacturer Petratto launched Digiroll, that takes sheets from the digital press and transports them to the final finishing process – stitching or perfect binding – on or off site. The system can handle 10,000 sheets, even with different kinds of paper. RFID is used for identification and location of jobs. IFS has been the UK distributor since last year.

The main message on Pitney Bowes big stand was its White Paper Concept, which ranges from document composition software and links to external data sources, through digital printing and finishing to mailpiece creation and inserting. We look at the concept in more depth on pages 49-50.

Significant deals were signed, including a sortation deal with a Turkish-based courier company, the first sale of an IntelliJet 20 inkjet we to Mexico, and a deal for insertion hardware and workflow software with a Swiss business process and IT outsourcing firm. In total the company closed more than £6 million of business at the show.

Polar introduced a new generation 5.0 of its Compucut automation system for guillotines. This can show live camera images with superimposed production information via JDF. When setting up the cutting program the operator sees relevant information within the image. For example, if part of the sheet must be laminated after cutting, the respective block can be omitted.

Several new guillotines were launched: the Polar 56 Net, 66 Net, 80 Eco and 80 NET. Also new was the N 78 single knife trimmer.

A novelty item was WiMotion, a guillotine operator’s wooden knocking block that incorporates a wireless system with two buttons to move the back gauge forward or backward. It works with the latest N Pro high speed cutters.

Renz was another company reporting significant sales. It took 50% more orders than at drupa 2008, helped by the launch of two new punching and binding systems.

The inline 360 is a high speed punching and binding system, where book blocks are dropped on to the infeed (conveyor), punched, re collated and fed automatically into the binder. This means less product handling and full automation of punching and binding. It’s said to be a world first. It’s can also punch and bind calendar sets with either nail hole or calendar thumb cut.

Also new is the P 360, a fully automatic modular high speed punch, with an output of up to 72,000 punched sheets per hour. It can handle mixed stock, including polyprop covers. Modular die insertion allows any loose leaf punch pattern to be punched.

Schneider Senator introduced a new machine control for its 78/92 and 115H/137H/155H guillotines. This includes a much larger 15 inch colour touch screen with graphical controls, plus USB and Ethernet data ports as standard.

The Senator E-Line 78/92 cutters also received some upgrades to the features, including a new knife change device, modified cut buttons and a folding rear table cover as standard. Friedheim is the UK distributor.

Scodix reported a record drupa debut, saying that 30,000 visitors on its stand (pictured above) took 250,000 of its samples. At the show it introduced the second generation versions of its digital embossing, raised-image UV inkjets, plus a new way to apply a digitally controlled glitter effect that it calls Rainbow. Both the new S74 presses on the stand were sold during the show and Acculink, a US user of the original Scodix1200 press, signed a deal to upgrade to a S74.

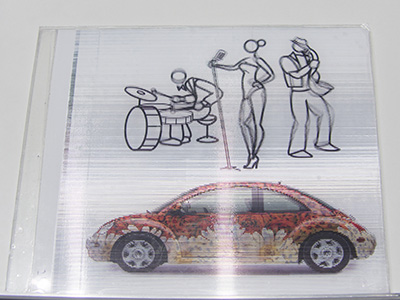

A 3D clear printed lenticular lens on Scodix’s stand. The images printed under the lens ‘flip’ as you change your viewpoint.

The S52 and S74 Pro inkjet presses (for 52 and 74 cm sheet widths) print Scodix’s PolySense clear UV-cured polymer. This is extremely glossy and very clear too: at the show the company was showing off test shots where it had printed optical strip lenses for lenticular flip image printing. These weren’t perfect but if the process can be perfected it will not only remove the need for expensive extruded plastic lenses but will allow lenticular effects to be applied as spot images for the first time.

The process is also used in the Scodix inkjet Braille technology, which not only produces Braille characters but could create raised diagrams and graphics. The letters and shapes created stay raised at the same height, never flatten and are very easy to sense-read.

The new Rainbow station is the world’s first digital inkjet glittering station. It’s fitted to the inkjet press and can add variable data sparkles to your print, in any colour. It’s aimed at gifts, greetings, wedding invitations, photo albums, cosmetics and novelty applications.

Tech-ni-Fold was demonstrating both its well established slitting and perforating wheel system for third party folders, as well as its new CreaseStream range that builds the system into standalone machines. The 52 cm new CreaseStream Plus has a new gravity and friction feed to take sheets from 70 g/m2 and above, running at up to 20,000 sheets per hour. Prices start at £9500.

The CreaseStream Auto model can run inline with a folder for speeds up to 12,000 A4 sheets per hour. It gained a new ability to be wheeled into the second folding station of a Stahl folder.

There’s also a new creasing rib matrix wheel called Endura Crease. This is specially developed for digital work and has softer rubber. It runs slower but gives a higher quality crease..

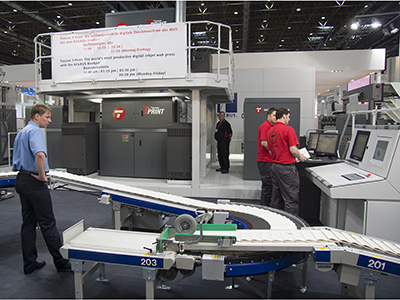

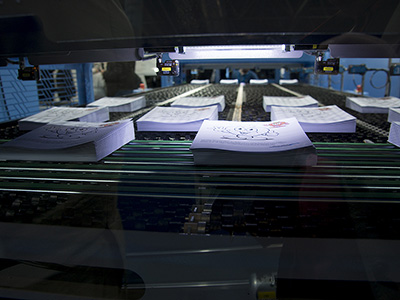

Timsons’ stand was dominated by its spectacular TPress line, which combined the TPrint very wide format (1320 mm) mono inkjet book press with a TFold variable format signature folder. The TFold is designed to work with any continuous digital web press, not just TPrint. It creates three sides open folded signature for all types of book binding.

The TBook line can also be used with any digital web press, and can make up to 4000 book blocks per hour. It can be installed as part of a complete book line or run as a standalone finishing system.

Japanese manufacturer Uchida Yoko’s big introduction was its AeroCut Quatro, a modular finishing system for SRA3 sheets up to 350 g/m2 (covered in detail in DP July, Finishing Line). This combines slitting, cross-cutting, matrix creasing and perforation functions for around £29,000. Morgana Systems now sells this in the UK.

The full Uchida range includes small format folders, foiling machines, drills, collators, collators and paper counters. It’s available through UMG in the UK.

Vivid Laminating Technologies recorded its most successful drupa. As well as its existing laminators it showed off a prototype new feeder for the Matrix Single Sided Laminators (designed for commercial and digital print work), which led to orders being taken on the spot. A new middle level Polarsign wide format laminator is available in both single roller and cold models in 1400 and 1600 mm widths.

Watkiss Automation showed a new version of its popular PowerSquare system for saddle stitching and forming square spines. This one is fitted with two extra knives to make a three knife trimmer, to handle digital colour work with bleeds. ‘It can also be used for very neat photo books,’ pointed out Jo Watkiss. ‘You pop them in a case and it looks great. You wouldn’t buy it just for photo books, but it’s a useful extra function if you’re buying one anyway.’

Wohlenberg introduced three perfect binders, called Quickmax, Vento and Phoenix. Quickmax is available in three versions: Compact, Halfline and Inline. All three are automated, with manual product infeed into the clamp on the Compact and Halfline, and inline product infeed on the Inline. Friedheim is UK distributor.

Xerox introduced a new automatic finishing solution called the IntegratedPLUS Finishing Solution for Booklets. It’s based around CP Bourg’s BSFEx dual mode sheet feeder (see above) which allows an inline finishing system on one press to accept and finish sheets from another, offline press.