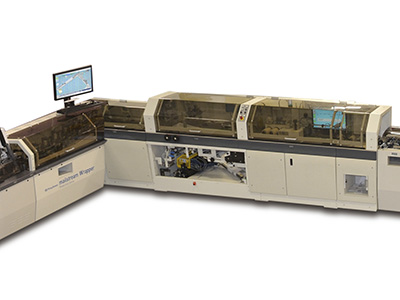

The Mailstream Wrapper components in a complete MPS line. The wrapper reel feed would be behind the open panel, but isn’t shown in this pic.

May’s drupa show saw the introduction of the Pitney Bowes Mailstream Wrapper into Europe.

This is a new option for its Mailstream Productivity Series (MPS) lines, intended to combine the advantages of high speed mail inserting with a lower cost and more flexible alternative to pre-formed envelopes.

In place of a standard envelope insertion module in the mail line, there is a paper wrap section developed and supplied by Sitma. This feeds paper from a reel and wraps and forms it around the ‘insertion’ (which isn’t really inserted as such, but enclosed). The wrap is folded, glued and cut and optionally given a scalloped flap edge, so it looks identical to a conventional envelope.

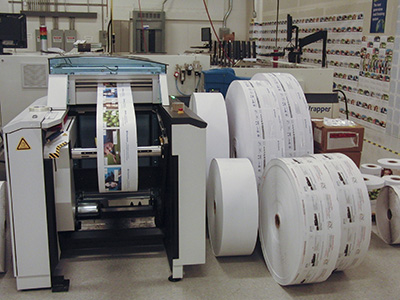

Not shown in the top image, this is the unwinder and feed system loaded with pre-printed wrappers, leading into the wrapping section.

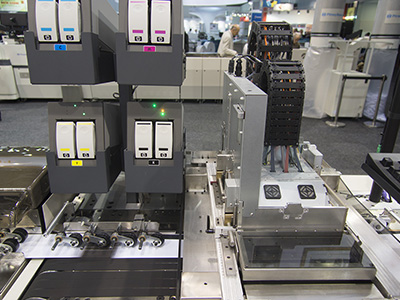

A diecutting windowing section can be incorporated in the wrap feed line. Alternatively (or additionally) the Pitney Bowes Print + Messenger colour inkjet printing station can add addresses and even full-colour promotional messages to the outside of the formed envelopes.

Print + Messenger is the inkjet personalisation station. It uses HP inkjet heads with Pitney Bowes constant head height technology. The print heads here are on the right; the four colour ink reservoirs are at upper left. Single or four-colour personalisation can be added to the envelopes or wraps.

‘Previously wrapping only worked for long runs with pre-printed messages,’ said Wilhelm Kanzler, the company’s director of product management for inserting solutions. ‘Now we can trigger personalisation from 2D codes on the document. This calls up the address details from a database, together with any personalised messages, images etc, and prints every envelope individually.’

For high volumes, Pitney Bowes recommends using one of its IntelliJets or similar digital presses to pre-print most of the marketing message onto the wrap reel (the part that stays the same) adding variable elements using Print + Messenger on the mailing line.

The wrapper feed can run at the mailing line speed of up to 26,000 pieces per hour, with fully variable downstream print. ‘A roll of paper can typically make 60,000 envelopes, so the operator isn’t changing it as often as boxes of pre-formed envelopes,’ explains Mr Kanzler ‘You may only reload a roll every two or three hours.’

Pitney Bowes estimates that working this way can save between 20 and 40% over pre-formed and pre-printed envelopes, through a combination of reduced paper usage, improved warehouse management and less scrap and waste envelope boxes.

Preformed blank envelopes cost more than using roll fed wraps. Compared with pre-printed envelopes, with customer’s branding, the costs savings are even greater: these need frequent changes plus careful management and storage to match up with the relevant documents on the mailing line.

The potential savings of wraps are therefore quite healthy even before you consider Pitney Bowes’ other main theme at drupa: the White Paper Factory. In last month’s Digital Printer this was explained by Gareth Stoten, PB’s vice president of sales for Pitney Bowes Document Messaging Technologies Europe. In brief, it means using end-to-end full colour digital printing to replace the older method of black-only overprinting of personalised messages and addresses onto pre-printed offset documents, letterheads, brochures etc.

The same applies at the mailing stage: using blank envelopes or wraps not only means you save on pre-printing, but it also allows the whole print run to be done in pre-sorted order for local post rounds.

If you print ‘white paper’ documents as well as envelopes, then you don’t need to organise your production runs as a series of client’s jobs, but you mix all the clients’ jobs together in the mailsort order. This qualifies for significant postal discounts. ‘This method also gives greater integrity so that the system can be used for transactional documents that have to be tracked and verified,’ Mr Kanzler pointed out.

‘It also works well with SLA (Service Level Agreements) such as a bank requiring that all its weekly statements go out by a certain time on a certain day.’

Here the outer wrap reel is folded around the inner documents. It’s then cut and glued to form the envelope.

If needed the paper rolls for the wraps can be pre-printed, using either offset or digital presses, although this loses the advantage of the mailsort ordering and would still require personalisation on the mailing line (unless you’re using window envelopes).

A possible next development, which Pitney Bowes isn’t commenting on, would be to put a higher volume colour printing station on the wrapper’s print path, upstream of the insertion stage.

Mr Kanzler was wary of quoting prices for what will often be a custom system. What he did say was: ‘The wrapping system costs more but its ROI is much better than envelope inserters because of the materials savings and greater flexibility. The capital costs don’t matter so much, because of the

materials savings.’

Contact: www.pitneybowes.co.uk