See also: drupa part 1: digital presses and drupa part 3: finishing

In part 1 we looked at the new digital presses announced at drupa in May. Here Simon Eccles examines the related software developments.

Agfa’s interest in the digital sector has shifted decisively to large format inkjet and the slow-selling dotrix continuous UV inkjet press is no longer made. However its Apogee range of pre-press front ends are still relevant to commercial digital printers as they support offset/digital hybrid workflows.

Shown at drupa was the latest Apogee 8 workflow management suite, featuring greater connectivity and driving more digital presses than before, including support for variable data. It supports 64-bit hardware and combined virtualisation (VMWare) to let high-volume printers consolidate processing. A new Merge Jobs function lets the system determine which jobs can be combined in one production run. There’s improved colour management and a new Acrobat plug-in to add a spot varnish layer to PDF jobs.

A new concept workflow was also demonstrated, with plans to deliver it next year. This offers three levels of production automation.

Apogee StoreFront is a new cloud based web to print system that is said to make it easy to set up online stores for both printed and non-printed products.

CGS’ ORIS Press Matcher // Web colour control software was shown on the company’s own stand plus presses on the stands of Xerox, Ricoh, Canon and Konica Minolta, where it was able to match results across the different machines (it calls this Cross-Fleet Colour Management). New for the show were the latest versions of ORIS Color Tuner // Web 2.0 and ORIS Certified // web systems plus new digital workflow products. A new UK distributor was announced:image2output.

The company also signed a deal to interface Esko’s Color Engine and CGS’ colour proofing products. Oris Color Tuner // Web users will be able to access the Color Engine’s spot colour library. This will be used in CGS’ flexible packaging proofing solution which outputs to a Roland VersaCAMM VS inkjet.

Another deal was for CGS to be a distributor of FFEI’s high end 3D packaging design, publishing and workflow products, including RealVue 3D Packager for 3D visualisation of pack designs.

The company also showed an interesting concept at the show, which was the ability to set up a display profile for an iPad, called ORISview. Normally this isn’t possible because the iOS operating system has no user-accessible profiles. CGS gets around this by using a standard X-Rite i1 colorimeter to read the iPad screen and then to calculate correction profiles and send them to an online server. When accessing soft proofs the iPad’s ID triggers the online profile so the colours are modified before they are sent to the tablet. This isn’t a product yet.

DALiM Software introduced new features for its ES (Enterprise Solution) production management and Virtual Library products that assist in file sharing and viewing. ES now has a Share feature to allow documents to be emailed to people who are outside the normal supply chain. This can be time-constrained for temporary access. The DALiM Virtual Library (DBL) page-turning job-progress tracker can now work with web browser so there’s no need for the previous client software.

The TWiST modular workflow and DiALOGUE progress-tracking engines have also been enhanced.

Direct Smile introduced the new version 5 of its Cross Media software, which makes it easy to set up personalised automated campaigns across print, online and mobile media. This requires no programming or HTML skills. The latest version enables the creation of mobile landing pages, sales and marketing apps and automated SMS sending. A new Dynamic Document feature allows users to produce a fully personalised document within the same browser used for website and email creation, so no external layout program is needed.

EFI had plenty to say about wide format and digital label printing, but also extended its front end offerings. In particular it announced the ‘Xerox EX server powered by Fiery,’ for the speedy Xerox iGen 150 high end press that was also introduced at the show. It’s based on the Fiery System 10 Rip technology and is fast enough to keep up with the high speed press, including variable data. New dynamic HD text and graphics, so far unique to the EX server, are said to give superior edge and text quality for all colour and saturation levels. The Image Enhance Visual Editor plug-in has been improved, for quick enhancement of individual images for tone, colour and sharpness.

At drupa EFI announced that users of Alphagraph’s Prinance and Printy MIS software can now switch to EFI’s entry level PrintSmith MIS for no extra charge. EFI acquired Alphagraph late last year and although it says it will continue to develop and support the software, it would rather switch users to the other platform.

Elpical launched Organic Imaging, a new brand of automated image enhancement software that it says will open up the market to publishers, photographers, creative studios and pre-media operations that couldn’t afford it before.

Based on Elpical’s existing intelligent image enhancement technology with downloadable client software and drag and drop workflows, it uses low cost credits, with the first 250 images free, and then charging under 10 Euro cents each (about 8p) for up to 5000 corrected images per month. The credits are pre-paid by credit card or PayPal and can be topped up whenever needed, with automatic top ups if required. There’s also a commission scheme for introducing new customers.

Enfocus’ commercial release at drupa of its latest PitStop Pro 11 and PitStop Server 11 preflight software had been flagged up months earlier. The new versions include ‘smart preflight and correction,’ avoiding the use of fixed and inflexible preflight profiles and making them dynamic to adapt to the job requirements, Enfocus says. A Variable Sets feature can respond to information in XML tags or JDF job tickets. New text support can automatically correct typos and also relink line endings so they can reflow if needed.

Esko showed its latest Suite 12, the overall name for its modular design and production/processing software for packaging, label, signage and general print. Suite 12 has new productivity and efficiency features thanks to closer integration of all the tools and engines, by increasing the 3D functionality and by enabling mobile collaboration and web based packaging management workflow.

Within the suite is the all-new Color Engine 12, a ‘breakthrough’ colour management workflow that incorporates the new PantoneLive system to predict spot colour behaviour. It predicts the appearance of spot inks on different media, including overprinting with spots. Users can add a plugin called Equinox to Photoshop to set up separations that use all the available gamut. GMG announced that its ColorProof and FlexoProof software can optionally connect directly to the Esko Color Engine.

Esko also demonstrated ‘lights-out’ automated production in conjunction with Indigo and Scitex digital presses on the HP stand. Esko’s colour solution is used in Indigo presses for industrial applications such as labels and tags and is co-marketed with HP Scitex large format inkjets for sign and display work. The Esko ArtiosCAD software was used to provide structural data to the Highcon Euclid digital cutting & creasing system (see Centrefold).

The Esko i-cut Suite finishing workflow was demonstrated on the HP stand, together with an Esko Kongsberg XP24 finishing table as part of an integrated, end-to-end workflow from design to finishing.

FFEI was showing its RealPro Workflow software, which it has been selling for the past year. It’s closely related to Fujifilm’s XMF workflow suite, which FFEI actually wrote, but RealPro Workflow is somewhat different and can drive other systems. A new Digital module features a powerful print-ready PDF and template imposition solution with ICC colour management and is said to be able to drive most digital presses.

It was also showing off its RealVue 3D Packager software for 3D on-screen visualisation of packaging structural and design files, which it can import from other production software (such as Esko’s ArtiosCAD).

As part of the demo it had commissioned a complex printed card model of the Bloodhound SST supersonic land speed record car project and was giving these out on its stand (see pic above). The point of this was that the files for the model could be viewed, rotated and assembled in 3D using RealVue 3D Packager.

RealPro 3D Packaging and a new RealPro Toolkit (a set of Illustrator plug-ins) can be bundled together as the RealPro Packaging Suite. These in turn can be bundled with RealPro Workflow to form the RealPro Packaging Workflow system.

FFEI is also moving into labels pre-press with RealPro Digital Labeller. This can complement the Caslon Inkjet Label Press that FFEI developed with Nilpeter (and showed on its stand with a new white ink module), or it can work with other presses.

Also new for the show was RealPro ColourCloud, a cloud-based application which it said significantly reduces the cost of creating high-end ICC Device Link and ink-optimised profiles. A 3D gamut viewer allows the user to visually compare profiles before printing a test image. A ‘try before you buy’ feature lets users test that it works before committing to buy the profile.

Global Graphics was showing off the results of independent speed tests of its latest generation Harlequin RIP, by Rochester Institute of Technology. These indicated that it can deliver pages well in excess of the rated speeds of today’s fastest digital presses.

Among the conclusions were that Harlequin Host Renderer can process 11x faster than the ‘leading cut sheet colour press.’ For publication work on a high volume wide web inkjet press (presumably an HP T400 or the like), when running with ten RIPs on a server, it’s 11x the required rate. For a medium volume press with one Rip, it’s 24x the rate needed.

New from GMG was CoZone, a new cloud based soft proofing strategy from the German colour processing and management specialist. ‘We didn’t feel that soft proofing really works,’ said Michael Farkas, marketing director. ‘CoZone takes the best ideas of soft proofing but for online access and hard copy proofs. You’ll be able to manage and share profiles and update software in the cloud. A delivery module can output hard copy proofs when needed.’

A cross media collaborative colour approvals product is also under development and will be ready by Q4, he said.

Also new was OpenColor, for simulating spot colours in packaging proofs. The GMG Production Suite, a production workflow for large format printing and finishing, was also demonstrated, having been launched at FESPA in February.

Heidelberg, which announced all sorts of moves into digital printing (see Digital Printer July), also had plenty to say about software. Some of this was extensions to its Prinect modular printshop networked workflow, including the global launch of Prinect W2P Manager, a web to print system. There was also Prinect Business Manager, a new MIS developed by CERM, the Belgian developer that Heidelberg acquired last year. It claims that Prinect is now the only printshop workflow to offer a fully integrated MIS. In the next development stage, the production workflow and MIS will use a common database, so job planning and production data will be available in the same system as, for example, job processing and materials management data.

‘Changes made to jobs at short notice will be implemented automatically in Prinect in terms of both machine selection and materials management,’ said Christopher Berti, head of Prinect and CTP at Heidelberg. ‘We are driving forward the merger of two system environments that have thus far remained separate in many areas despite JDF integration.’

Helios, a German software developer that originally specialised in OPI image servers, showed how it has developed its technology into a general image workflow engine. It can handle multi-stage workflows from preflight to soft proof and output, running as virtual servers on any platform. Its high performance web server allows remote access to job and image files. It’s also developed a way for iPads to access the online file structure (they can’t usually do this) and download them for offline access, with automatic synchronisation.

Hybrid Software is a relatively new company that was at drupa for the first time, but it reported that it had run 580 demonstrations of its products throughout the show and took orders worth more than 1 million Euros. It has developed what it calls the Order Lifecycle Management concept, which treats integration as a product, overturning conventional thinking about how to integrate hardware, software and workflows. This is designed for use in all areas of print, from commercial offset and digital to packaging, labels, inkjet and the screen/sign markets.

The Facelift software for browser-based job ticketing and automation is its biggest seller. It also has a production scheduler called Taskforce. Its Proofscop system for online soft proofing, annotation, viewing and editing was extended at drupa by Proofscop Live, which allows last-minute file corrections by remote web browsers, using tablets or smartphones if needed.

The new Hunkeler Control Solution is a modular system for planning, control and monitoring of production processes related to its paper handling systems. It has five stages: Mail Tracker for product recording and tracking; Print Processor for production preparation; Workflow Monitor for quality control; Site Manager for centralised process supervision; and Production Reporter for recording and quality verification.

Kodak extended its software tools, with new Prinergy version 6 workflow, an iPad application for the InSite portal suite and new versions of the Colorflow colour management system and PREPS imposition software.

Its Intelligent Prepress Manager 2.0 is a new generation of ‘connected proactive services’ for commercial printers. Users can manage their prepress systems anytime, anywhere, from a smartphone or other mobile device. Intelligent equipment monitoring and reporting, coupled with smart alerts, keep the user updated.

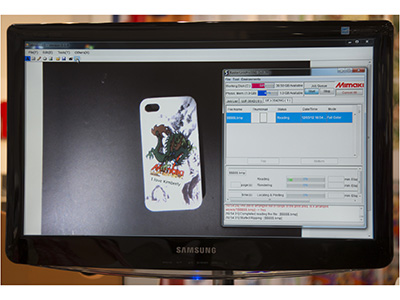

Mimaki previewed very smart camera based print alignment on one of its UJF-3042 compact A3 flatbed UV inkjets. An object to be printed (say a phone case) was placed anywhere on the bed without careful positioning. A camera above the bed would detect this and the software would identify its position, then rotate and scale the print image to fit, and finally print the image precisely in position.

Objectif Lune, the variable data software developer that acquired rival PrintSoft last year, said it had ‘outstanding outcome’ from its drupa presence. Its PrintShop Mail is for personalised promotional printing and its PlanetPress Suite is for transactional printing and workflow automation. PlanetPress EnvelopeNOW is a version for controlling workflows that involve mailing insertion lines.

PlanetPress Capture is designed to work with the Anoto Digital pen, a real pen that includes a camera that captures data as it is written, including handwriting recognition fields, and uploads the data to the PlanetPress production server. The Capture software sets up fields in forms that can be recognised by Anoto pens.

Optimus marked its 30th birthday with a new logo at drupa and showed its latest products. The Optimus Cloud web to print system integrates with its Optimus 2020 and dash MIS lines. Two sales tools were introduced for dash users: Sales Manager, which analyses data captured by the MIS for sales successes (or failures); and Campaign Manager, which allows the creation of email and other marketing campaigns based on the results from Sales Manager. Also new was Cloud Mobile, which allows sales staff on the road to access the MIS remotely via iPads.

It also announced a partnership to integrate the dash digital MIS with Pitney Bowes’ DF Works software to provide an automated workflow for transactional printing and mailing.

Pageflex’s iWay 6.0 web to print system gained new globalisation features to support multiple languages and currencies, plus the Server Customisation Engine from its high end page composition and variable data systems. Users can create highly customisable documents to include in their iWay web portals.

UK photo products oriented web to print developer Pixfizz introduced a new ‘Cloud to Print’ solution that allows users to create multiple customised storefronts and products for access by any web enabled device, including tablets. It’s an SaaS subscription based service.

Pixfizz also introduced a set of ‘go-to- market’ packages that target specific market segments. Each pack includes storefronts optimised for a particular application workflow with fast customisation for rapid start-up.

A new transactional workflow was announced by Ricoh for its InfoPrint range of fast printers. ProcessDirector Express is a version of the existing high end ProcessDirector, aimed at mid-range users and supporting PDF as well as AFP workflows. It can automate end-to-end print management and provides a dashboard for quick status checks of every job and document in the system. It can also integrate with third party tools, including Enfocus PitStop preflighting and Impostrip On Demand digital automation software.

The PDF Mailroom option can handle and track combinations of several PDF jobs, while demonstrating integrity to meet regulatory requirements and postal optimisation. It also allows for automated reprint calls.

Also new is Enhanced PDF Workflow, a family of products that lets users optimise PDF datastreams for high-volume production, with automatic preflighting and imposition via PitStop and Impostrip.

Screen has been talking about its forthcoming Equios universal workflow for digital presses and platesetters for a couple of years, but finally launched it at drupa. Ultimately it will replace Trueflow, its previous workflow that was developed primarily for offset plates.

A single interface drives production from web to print to delivery of the finished item. It can be used with Screen and third party devices. It can also be integrated into any web to print workflow so that web ordering automatically generates a print queue and associated finishing instructions.

The company also previewed its forthcoming cloud based variable data application, due for delivery some time in 2013. It’s said to simplify the generation of variable data jobs, with collaborative tools accessed by web browser.

Taopix was showing the latest features of its Photobook software, version 3.2, which it also calls Portfolio This gives online users better text and layout control, a new Photofix module for common image enhancements and fixes, plus options to upload to social media. A new External Photo Editor Link function allows the end user to perform advanced photo retouching and editing functions by launching third party applications.

Ultimate Technographics showed software to optimise the digital production of books, on-demand collateral and transpromo, from prepress to finished products. It was demonstrating in 12 locations at the show.

Ultimate Bindery 2.0 is a new version of its open JDF server for in-line and near-line finishing. It’s said to eliminate makeready times and reduce paper waste.

There was also the new Impostrip OnDemand Scalable, a digital-oriented imposition system, claimed to be the world’s fastest solution for high-volume cut-sheet or web presses, suited for use with on-demand books.

It also showed Impostrip 9.2 with AutoFlow fully automated free-form ganging, including flatwork optimisation for wide digital presses.

German database publishing and web to print software developer Werk II demonstrated its priint.suite software in the innovation parc area of the show. This comprises three main components: comet, for automatic generation of InDesign documents from database content; adjust, which adjust layouts automatically to fit in variable-size content; and timex, which helps to plan collaborative planning meetings. It’s available in the UK through jCatalog.

Xanté announced that its iQueue 7 workflow software was going to be available as a multi-site license after 1 June. This is free to current iQueue users. Now all users within a network can access the iQueue Ultimate features, including full job control, screening and halftoning controls, independent CMYK density controls, job cost estimation, and imposition for the Xanté Ilumina, PlateMaker, FilmMaker and ScreenWriter output systems. It also offers ‘advanced colour intelligence’ for use with the Xanté Excelagraphix 4200, a fast 42 inch wide hand fed sheetfed printer based on Memjet inkjets. Also new within iQueue is Right-On spot colour matching capability for digital presses.

Xeikon announced Color Control, a new cloud based colour management program for document imaging as well as label and packaging applications. This includes spot colour simulation. It creates conversion tables for specific spot colours to print on the CMYK Xeikon presses, which are then loaded to the Xeikon X-800 front end.

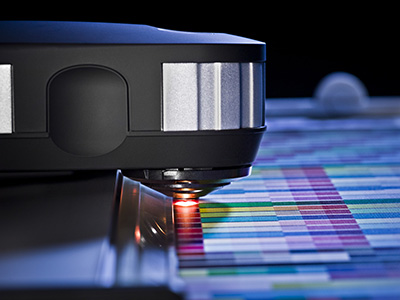

X-Rite introduced its brand new i1Pro 2 spectrophotometer, that replaces the widely used original i1 Pro and can be used with a revised version of the i1Profiler colour profiling software it introduced last year. Apart from the very different external casing there are major changes to the sensor inside.

A new spectrophotometer platform was also unveiled for pressroom use. It’s said to solve the problem of matching colours on papers treated with Optical Brightening Agent. It can also connect users to the PantoneLive ‘ecosystem.’ It is also embedded with the X-Rite Graphic Arts Standard (XRGA).