Post-GDPR, direct mail is thriving for those who have the data and generating real results for its clients. Michael Walker visited two printers who do to see what they’re doing and how

As the backlash against digital advertising continues and concerns over surveillance by social media giants grow, direct mail is steadily continuing to prove itself as an effective medium for acquiring customers and generating sales, as two companies in Yorkshire prove.

Lettershop

With sites across Yorkshire, YM Group has been active in mail personalisation since the 1980s, initially via mono laser printing on litho pre-printed shells to drive customer acquisition for mail order catalogue and financial clients via its Leeds-based Lettershop operation.

While the idea of the ‘white paper factory’ in which every element in a direct mail campaign is printed digitally has been touted by press vendors for some years, the approach at Lettershop has been built around honed hybrid systems over the years. Managing director Simon Cooper explained, ‘Digital [print] was sold around ‘sexy data’, with every copy different, but you have to be able to justify the price increase, based around the variable percentage of the page, which could be quite low.’

The company built what Mr Cooper says was the first hybrid litho-digital system in which a strip of name and address data in a subscription renewal letter could be printed digitally. This mode of production still accounts for around 80% of the direct mail production, which is largely focused on one-piece mailers, but with clever planning allowing letters, cards and other mailshot elements to be printed and digitally overprinted from the same sheets then cut, folded, glued and assembled or inserted as necessary. The company produces PDF artwork for these complex jobs itself from clients’ InDesign files, and advises on the creation of suitable templates to accommodate the various layers and cutting guides.

Growing demand for ever-larger variable areas in mail products, including full colour, meant that a wider inkjet web system was needed; the Nexpress was pushed to 1.8 million copies a month compared to its recommended volume of 500,000. ‘We were hammering it 24/7,’ as Mr Cooper put it.

As with many high speed inkjet projects, a key concern was the ability to print on existing substrates. ‘We need it to print on the same regular papers, at litho quality, with one file for colour and mono integrity,’ explained Mr Cooper. Kodak’s pre-coating approach with its Prosper technology ticked that box, though its solution could only coat one side, which meant rewinding and coating the other side first for duplex work. Lettershop therefore built its own double-sided inline coating unit, which allows the press to run at its full 300m/min speed; Kodak has expressed interest in commercialising this outside Europe.

Another attraction of the Prosper technology was its continuous flow recirculating printhead design, which Mr Cooper says is better than drop-on-demand inkjet types as is allows the ink to carry more pigment and so better supports a wider range of stocks. Daniel Lynan, prepress and digital print manager, agrees, adding that some ‘digital’ papers give a smaller colour gamut.

The Prosper system has been used for mailings that run into the millions for household names like Sky, Marks & Spencer, Holland & Barrett and Tool Station. ‘It runs and runs,’ says Mr Cooper, while Mr Lynan explains that the cost of coating adds about £50 to the £600 per tonne for normal offset paper compared to about £1300/tonne for ‘digital’ paper. The Prosper’s various screening modes have been explored and algorithms have been developed in-house to optimise print quality on the various papers, including uncoated, silk and gloss.

Another quality control feature is colour consistency. Mr Lynan explains, ‘A small sheet-fed toner press varies across a single pallet. The Kodak doesn’t, we get delta-E of 2 across a year.’

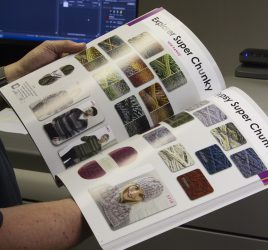

Fretwell’s work includes both DM campaigns and book print for the wool industry

The company is now adding a spot gloss system that it has built itself and which will handle papers between 90 and 240gsm which should address the majority of applications, including the ability to add scratch-off, glitter or fragrance coating. Another application that Lettershop has pioneered is printed paper wraps for magazines which replace polywrap bags. As well as environmental benefits, this allows for personalisation of the wrapper, to carry advertising or other promotional messaging.

Continuous testing is part of the development strategy at Lettershop, and one of the recent trials has been around partially addressed mail, which targets street addresses but not individuals. In response to privacy concerns about ever more intrusive online activity surveillance that GDPR can only partially tackle, this seems a happy medium.

Mr Cooper explains, ‘You can acquire customers by providing local information, maps and adverts. Retail loyalty is there but there is a point where it’s over-personalised; we’re now driving ‘where you live’. For example, we can target areas around charity shops, addressing the community for donations or volunteers, or send things to ‘the DIY expert’ which reaches potentially everybody in the house; barcodes on the back of coupons can be scanned to test the street or area-level response. We’re incredibly excited about this.’

Fretwell Print & Direct Mail

Things run on a slightly smaller scale at Fretwell Print & Direct Mail, where a Heidelberg Versafire EV press has been in operation producing full colour direct mail items – amongst other things – since January 2019. The new toner press, introduced last year, replaced a seven year-old Ricoh model in order to provide increased throughput.

Set up in the 1960s, Fretwell built its business around printing wool trade magazines and still produces knitting patterns and books. Today the company is located in Keighley and serves clients in the retail sector, many via print management clients.

The Versafire EP press that Andy Gillett installed has seen DM production rise by 25%

Fretwell has been involved with direct mail operations for around ten years, particularly in the charity/nongovernmental organisation sector and for historical reasons has a strong connection with Ireland, and prints for the vast majority of the republic’s charities. Typical jobs include six-page A4 mailers for Christian Aid personalised to 25,000 recipients, a 35,000 run A6 postcard for Shelter, or a 400-piece mailer on uncoated stock with gloss laminate for L’Oréal. Direct mail now accounts for more than a quarter of the business.

Part of the reason for switching to the Heidelberg digital press was its integration with the German manufacturer’s workflow. ‘We’ve had Prinect since 2001 for our computerto plate and [litho] presses,’ explained joint managing director Andy Gillett, ‘We took some convincing, but we saw the integration of the DFE and we knew Prinect Cockpit very well.’

Mr Gillett reports that the volume of direct mail work has risen by 25% since the installation of the Versafire and suggests that this is at least in part due to the extra speed of processing personalised print that comes through the Heidelberg DFE’s support for PDF/VT.

This version of PDF was launched over 10 years ago and intended specifically for this type of application (VT stands for variable transactional), though for a variety of reasons it’s not seen a great deal of take-up, with the high volume transactional houses sticking to tried and-tested but less graphically capable alternatives. PDF/VT is designed to speed processing in the RIP/DFE by splitting the repeating parts of the document from the variable content and holding the former in memory so that only the latter need to be processed for each new page, rather than processing the entire page each time.

At Fretwell, the impact has been considerable. ‘It used to be RIP, print, wait for each page,’ said Mr Gillett, adding, ‘the press would run at less than half its rated speed. Since getting the Versafire EV, we can run at maximum output.’

Preparation of PDF/VT jobs involves the use of a Prinect plug-in to Adobe Acrobat that allows the variable content parts of the document to be identified and to be populated from data records supplied by the client. The variable part is typically only text but can be images appropriate to the recipient as well. Prepress manager Stephen Lloyd also explained that Prinect also has a 1000-page limit for PDF artwork, so a 14,000 run personalised job would previously have to be split into 14; with PDF/VT, the system effectively sees a job of the same pagination as a finished product, but printed multiple times, so there’s a further time saving in production management.

Fretwell also has a pair of Konica Minolta AccurioPress 6136P 136ppm mono digital presses which it uses for overprinting on litho shells as well as for ‘proper’ work including both line art and photographic images. ‘They have superb image quality and are not just for name and address printing,’ commented Mr Gillett. These are also used extensively for charity mailing campaigns – a Concern mailing to raise support for victims of Cyclone Idai was ready in 72 hours. Finishing items include a Buhrs four-station inserter and an Astrojet M1 colour inkjet envelope printer which again features strongly in charity work: ‘It helps charities get their letters opened,’ he added.

Colour matching across digital and litho output was another factor in favour of the Heidelberg digital press and workflow combination and not just for direct mail work. Fretwell’s ongoing work for the wool trade includes items like the annual King Cole Shade Book which acts as a colour guide, so accuracy matters. For the 2019 edition, 100 copies were needed for a trade show, so were printed digitally, with the balance of 3500 to be printed litho. Mr Gillett and his customers are happy that both version match.