There is a growing number of affordable direct-to-garment printers that allow existing print service providers to take advantage of this expanding market sector. Nessan Cleary looks at the models

Most people would assume that there’s very little crossover between the print industry and the fashion world, yet the growing trend towards printing clothing offers printers a way into the ‘fast fashion’ business. There has always been demand for very short-run clothing, typically things like workwear or school sports kit, and local wide format printers have often satisfied this demand. But the current trend for personalised and short-run clothing goes far beyond this and is mostly driven by millennials’ desire for personal expression whilst also appearing smartly dressed.

Ronen Samuel, CEO of Kornit, says that this is also linked to increasing use of e-commerce, noting, ‘Even five years ago you would not order your shoes or garments online because you would want to wear it first but now it’s very easy to order things online.’

For now, most of these printed garments are personalised, with individuals ordering items and customising them for their own needs. But most vendors recognise that as the trend persists there will be other opportunities with established brands and retailers that will involve longer print runs.

There are several direct-to-garment printers that offer a very easy way into the short run market by printing to blank ready-made items and so cutting out the need to actually manufacture the clothing. This includes things like t-shirts, but also tote bags and hats. The materials are mostly cotton and natural fibres, which satisfies a broad range of consumers, rather than the polyester used in dye sublimation and which is mainly aimed at sports and leisure wear. The choice between machines largely comes down to volume, ranging from small desktop printers that are good for testing the market, right up to more industrial machines, though most of the latter print direct to fabric rolls so that you still have to assemble the final garment.

Desktop printing

Ricoh acquired the American company AnaJet a couple of years ago, which has led to the development of the Ri-series of three desktop printers, all of which use Ricoh printheads. The smallest of these is the Ri 100, which prints mainly to cotton, including blends of at least 50% cotton. There’s a matching heat press, the Rh 100 Finisher, which has the same 399 x 698mm footprint so that the printer can be stacked on top of it, which makes for a compact solution.

Then there’s the larger Ri 1000, which was launched earlier this year. This prints to cotton and cotton blends, polyester, wood and canvas. It uses CMYK plus white, with recirculation of the white ink. It takes magnetic platens that hold the garments in place. These platens are available in multiple styles and sizes up to 40 x 50cm, which snap on and off the machine so that it’s easy to load new garments for printing. It can deliver a full colour CMYK 10 x 8in graphic in 28 seconds, or 42 seconds at ‘Fine’ print quality.

The top of the range model is the Ri 6000, which prints on a wide range of materials ranging from cotton and light polyester to mixed polyester garments up to 50/50 blends. It uses water-based pigment inks from AnaJet, printing CMYK plus two white channels. It comes with AnaRIP software, which gives control over the print settings as well as predicting ink costs.

Epson is best known for its wide-format printers, including a number of dye sublimation models, but the company also sells a direct to fabric desktop printer, the SureColor F2100. This is mainly designed to print to cotton to produce items such as t-shirts, sweatshirts, polo shirts and tote bags. Naturally it uses Epson’s own PrecisionCore TFP printhead and UltraChrome DG ink. There are five colours – CMYK plus white. It features a fabric platen grip pad and platen grip tool to make garment placement easier and there are also spacers for more accurate platen gap adjustment. It also comes with Epson’s Garment Creator software, which allows users to add text and multiple images as well as setting up hot folders to queue jobs.

The Australian company DTG Digital produces a number of direct-to-garment printers, including the G4 that was launched last year. It uses Ricoh print heads with 1200dpi resolution and also prints CMYK plus white. It uses magnetic platens, with different platens available for handling a range of products. The company estimates that it should be possible to produce up to 36 shirts per hour, depending on the size of the print.

Ricoh launched this Ri1000 desktop direct to garment printer earlier this year.

Wide-format

Most wide format vendors also offer dye sublimation roll-fed printers for printing to transfer paper, with many also able to print directly to polyester-based fabric though this process still needs a heat press or calendar to cure the printed fabrics.

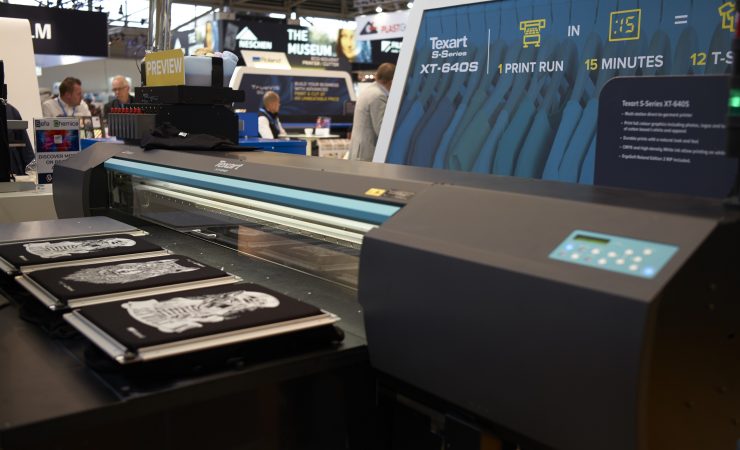

Roland has developed the Texart range of wide format dye sublimation printers, which can print to both sublimation transfer paper and direct to fabric. However, Roland Europe has gone a step further, putting the print carriage from the Texart 640 roll-to-roll machine onto a flatbed from the Italian company SmartColor to create a flatbed production machine, the Texart XT640S, shown as a prototype at Fespa 2019 in Munich. But whereas the roll-fed version is a dye sublimation printer, the flatbed uses pigment inks that are suitable for printing direct to cotton. It prints CMYK plus a high density white ink.

The bed holds a set of jigs, with a choice of nine XL-sized or 12 standard size, which are designed for holding cotton t-shirts in place. It takes 15 minutes to print to all the jigs though you can be loading or unloading the jigs at the front of the bed while it’s printing to those at the back to achieve a reasonable throughput. It should be available commercially by the end of this year.

Mimaki has also taken the basic dye sublimation printer a stage further with its TX300 printer, which has two sets of printheads, ink tanks and lines. This means it can be simultaneously loaded with two sets of inks so that users can easily switch back and forth between the two types, for printing to transfer paper or materials, depending on the application in hand. The latest version can be configured with three different ink combinations: textile pigment and sublimation transfer; direct sublimation and sublimation transfer; or textile pigment and direct sublimation. It also features an interchangeable platen with an ink-receiving ‘ditch’ for printing direct to textile and a vacuum platen for transfer paper.

Mimaki has also developed the more productive Tiger 1800B. This is available in both a sublimation and a direct- to-textile version, with the latter using reactive inks capable of printing to cotton, silk and rayon, although it requires pre-treated substrates.

Kornit’s Avalanche PolyPro avoids pre-and post-treatment.

Industrial strength options

Kornit has developed a number of industrial t-shirt printers that use dual platens to hold the garments. In theory you could use these to produce various products such as tea towels and tote bags but t-shirts probably make the most economic sense. They all use the same basic chassis with the difference mainly being the ink set.

The latest is the Avalanche PolyPro, which uses the NeoPoly ink. This ink set is made up of inline fixation, a white base layer, followed by CMYK and finally a new Poly Enhancer channel. It’s a wet-on-wet process where the fixation, which is sprayed on first, holds the ink in place and ensures that

it doesn’t soak into the fabric. It chemically bonds the ink pigments so that the colours sit on top of the white layer. The Poly Enhancer is a clear fluid, which acts like a catalyst to reduce the drying temperature from Kornit’s usual 160°C to 100-110°C, which eliminates the risk of dye migration where the colourants from the polyester can diffuse into the white layer. A further advantage is that the inks are odourless. It prints on polyester and polyester blends and can produce up to 85 A4 images per hour.

In addition to this, Kornit has also developed a roll-fed printer chassis, the latest version of which is the Presto. This is a 1.8m wide roll-to-roll printer that also includes

a separate drying and curing unit, with a sticky belt to transfer the printed material from printer to finishing unit. The Presto print six colours – CMYK plus red and green – with the basic model having three heads per colour plus another three for the fixation, so 21 in total. There’s also a Presto S with double the number of heads that is twice as fast.

There’s no need for either pre- or post-treatment thanks to a water-based fixation solution that’s jetted through a printhead exactly where the ink drops are due to be placed. The fixation acts as a binder, holding the pigment ink to stop it from spreading. This allows the Presto to print to virtually any type of fabric, including natural and knitted materials.

Epson has produced a range of Monna Lisa Evo Tre industrial textile printers through its For.Tex subsidiary. This includes the entry-level Tre 8, which has eight of Epson’s PrecisionCore heads, down from the 16, 32 or 64 heads of the more expensive models. It can produce up to 265sqm/ hr at 300 x 600dpi in a single pass, although multiple passes will yield better quality. It’s 1.8m wide and uses Epson’s Genesta acid, reactive, disperse and pigment inks.

EFI sells a number of textile printers, with the most recent being the Reggiani Colors. This has 12 colour channels and can be configured with different types of inks including special inks, inks of different chemistry types, and chemistry for special treatments such as higher-penetration printing, all at the same time. It can also be set up with two sets of six colours for faster throughput. It can produce up to 560sqm/hr with a print width from 180 to 340mm.

In conclusion, one of the main considerations is the need for pre- and post-treatment of materials for inkjet printing. For lower volumes, a desktop machine printing direct to a pre-made garment is the most cost-effective way into this market. But higher volumes offer more flexibility in the choice of substrates and the option to manufacture your own products. Either way, the sheer size of the garment business represents an opportunity that few print service providers can afford to ignore.