Norfolk full-service printer Blackwell Print has ‘enhanced’ its inhouse binding and trade service offering following investment in a Horizon BQ-270V single-clamp perfect binder from Intelligent Finishing Systems (IFS).

Tom Davidson, managing director of Blackwell Print, explained that the investment was made in order to get a binder for longer runs that could complete more work inhouse. Having looked around other businesses running the Horizon BQ-270V, he described the machine as ‘robust’. The company now produces 80% of its perfect binding inhouse compared to the previous 20%, he added.

The Horizon BQ-270V includes an automated, sensor-activated digital caliper system which measures the book block thickness and automatically transfers this data to the binder, offering on-demand production of variable thickness books. It also features a 10.4in colour touchscreen, job programming, and a compact configuration.

The new addition has settled in well and has already opened doors to new opportunities, said Mr Davidson. He continued, ‘In the few weeks it has been running we have already completed 10,000 to 12,000 books. It has also enabled us to offer a trade service, which is something we hadn’t considered until a local business came to us asking for our trade prices. As a result, we expect it to achieve return on investment in six to eight months.’

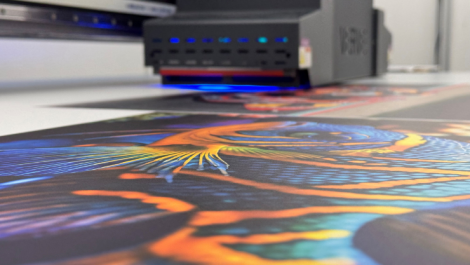

Founded in 1870, Blackwell produces litho print on a Heidelberg XL75 four colour press and digital print on two Xerox Versants 4100s.