Screen Europe will be showcasing its inkjet printing solutions under the theme ‘Powering Print Connections’ at Hunkeler Innovation Days, which runs from the 24-27 February, in Lucerne, Switzerland.

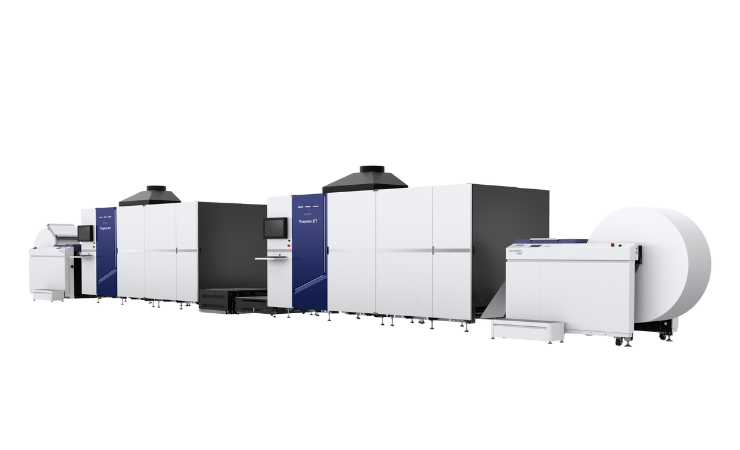

On show at the Screen booth will be its Truepress JET 560HDX; the new Truepress JET 520NX AD; and IBIS Bindery Systems’ saddle stitch binding system.

To be unveiled at the Hunkeler show, Screen’s Truepress JET 520NX AD is engineered for transactional and direct mail printing, printing at 225m/min, and setting a new standard in high-speed performance for the transactional printing market, explained Screen.

The machine will utilise Truepress Ink NP, a high-density pigment ink, which can be used to print designs and legible text on thin 40gsm substrates. JetInspection, a built-in inspection system, will also be demonstrated on the machine. It enables real-time scanning of the surface of all pages in a job with customer batch number codes printed during production for 100% traceability.

The company will also showcase its Truepress JET 560HDX. This press combines printing precision with finishing equipment integration. Live demonstrations will illustrate the new Truepress SC2 Ink which the company claims can produce resolutions of 1200dpi at speeds of 120m/min without primers on offset-coated papers. Screen will also display advanced variable data printing functionality with PDFormstudio workflow software handling design data.

In line with the theme, ‘Powering Print Connections’, IBIS Bindery Systems’ saddle stitch binding system will provide visitors with a window into digital print production, processing printed rolls from digital inkjet presses as they are saddle stitched and bound.

Screen will also supply rolls printed on its Truepress JET 520HD+ system with SC+ inks to the Hunkeler and Horizon booths. The company will also provide support during both companies’ demonstrations using control barcodes generated by Equios, its software platform which shows, in real-time, the transitions between different jobs within rolls during postprocessing.