HP has made what it says is a ‘major breakthrough’ with HP ThermaCore, a ‘next generation’ thermal inkjet (TIJ) technology, that the company believes redefines printing performance in coding and marking applications.

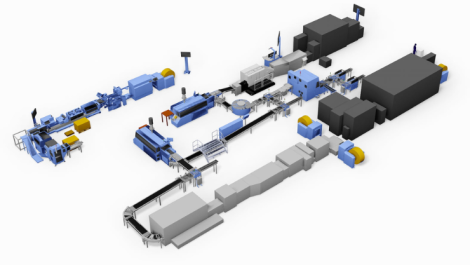

With speed, precision, and adaptability, HP ThermaCore enables manufactures to improve efficiency, meet global coding standards, and reduce operational costs. HP said the new technology addresses the challenges of traditional TIJ solutions which often fall short due to limited throw distance, slower speeds, and complex stitching, leading to inefficiencies and production delays.

ThermaCore enables three times the throw distance, twice the print swath, and twice the printing speed of previous TIJ generations, according to HP. Designed to meet the demands of high-speed packaging and marking applications, HP said ThermaCore’s up to 9mm throw distance allows for printing on non-flat surfaces, seamless wide-format printing without stitching, and reliable operation in the most production environments.

Its 23mm print swath eliminates the need for stitching, ensuring adaptability and efficiency for industries ranging from food and beverage to pharmaceuticals and consumer goods. And with printing speeds of up to 120m/min HP ThermaCore also integrates into high-speed packaging and filling lines, the company stated.

On top of performance upgrades, HP ThermaCore addresses sustainability. Based on HP internal data, the new printhead is made with at least 65% recycled plastic in the cartridge body and improves ink efficiency to minimise waste.

The new technology allows HP to enter and compete in markets which have been dominated by continuous inkjet, laser, and thermal transfer overprinting technologies, it explained.

Visitors to SinoPack 2025, which runs from the 4-6 March 2025, in Guangzhou, China, can witness ThermaCore on the Meenjet and Sojet stands, where there will be demonstrations showcasing the technology’s capabilities in real-world applications.