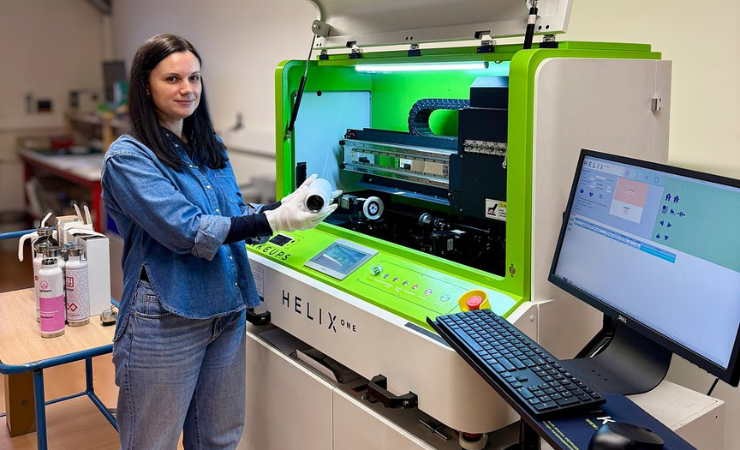

Austrian print and design company Koller Media has expanded its production capabilities with the installation of an Inkcups Helix One direct-to-object cylindrical printer. The investment marks a strategic move for the company, allowing it to diversify its services and meet growing demand for personalised and customised print products.

The Helix One is designed for high-quality, high-speed printing on cylindrical objects such as decorative candles, bottles, drinkware, and packaging, using a range of materials including glass, metal, and plastic. Its ability to print with white ink and varnish was a key factor in the investment decision, along with the machine’s compact size and options.

Koller Media has traditionally offered customised printing solutions for industries such as marketing, food and beverage, tourism, and manufacturing. The company identified direct-to-object cylindrical printing as a growing market opportunity and quickly built demand for the new service.

This investment makes Koller Media the first company in Austria to adopt the Helix One, reflecting the increasing demand across Europe for personalised products. With the new technology, the company has already produced dishwasher-safe water bottles, thermal bottles, and various candle designs, and is now exploring further applications, including conical cups and expanded drinkware options.

Managing director Robert Koller sees direct-to-object printing as a major step forward for the company. He stated that the company is already seeing strong interest and new market opportunities, and he is looking forward to further developing this area of the business.