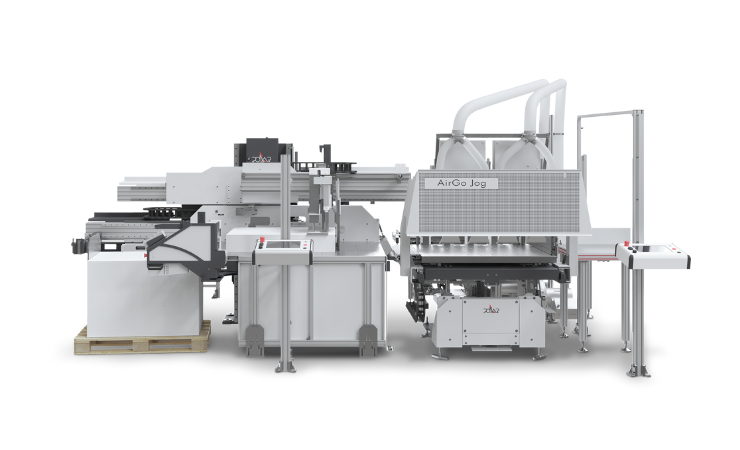

Polar has announced the successful delivery and installation of its AirGo Jog finishing system at a customer site in France earlier this year.

The system has been lauded by the customer for the numerous benefits it brought to their business. These include improved ergonomics, enhanced working conditions for operators, a significant reduction in staff absences, and increases in productivity and profitability.

Polar believes the AirGo Jog stands out by enabling unmanned product preparation, achieving a processing speed of 90 to 120 seconds per 14cm cutting layer. Unlike traditional systems, which require at least twice the time, the AirGo Jog completes the entire cutting layer in a single operation, boosting efficiency.

The machine has a high level of automation, eliminating manual tasks such as material transport, separation, and the fanning of sheets. The system’s versatility is evident in its format range (50 x 70cm to 78 x 106cm) and automatic height scanning, which accommodates various layer heights without requiring changeovers. This makes the AirGo Jog particularly valuable for the fast-growing Web2Print sector.

The system’s human machine interface simplifies operation, and the high level of automation reduces setup times, requiring just one operator for the entire cutting process. Additionally, the AirGo Jog’s modular design allows for retrofitting to existing systems or use as a stand-alone solution.