The Brother GTX direct-to-garment printer

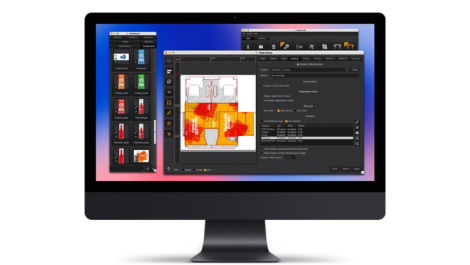

CADlink has created all-inclusive colour management, production workflow software for the Brother GTX direct to garment printer.

Extending colour gamut and reproducing a greater colour range, CADlink’s Digital Factory Apparel Brother Edition software is designed to maximise colour output as well as the throughput capabilities of the newly released Brother GTX printer.

‘Digital Factory Apparel Brother Edition is much more than RIP software,’ stated Michael Chramtchenko, CADlink Technology’s director of marketing, who cited the company’s “advanced colour management controls” as well as pre-production workflow and image preparation tools. ‘Most importantly, these tools can all be found in a single, easy-to-use package that addresses all of the production requirements that Brother DTG printer users may have,’ added Mr Chramtchenko.

The software features an assortment of production automation features including the ink and time saving “knock me out” tools that automatically remove specific design colours that match garment colours eliminating the need for ink to be printed in those areas. Also included is advanced handling of white ink management.

Users can select and create predefined print queues that are based on colour or type of garment, resolution requirements as well as preferred colour printing requirements – realistic or vibrant.

A custom print driver as well as specially created colour profile sets for white, black and coloured garments are all available in the currently shipping Digital Factory Apparel Brother Edition Version 3 software product.

The currently shipping version also supports existing GT-3 Series Brother printers, enabling existing Brother users who purchase the new GTX printer the ability to use a single software package to print to both machines. Existing Digital Factory Apparel users can add on the new GTX printer package for a small fee.