Tech-ni-Fold’s video explains the Tri-Creaser’s simple concept

Tech-ni-Fold has posted a video online that explains how its Tri-Creaser works to enable folding of toner-printed products without flaking or cracking.

According to Graham Harris, managing director of Tech-ni-Fold and inventor of the Tri-Creaser, due to the increased quantities of recycled papers in use, flaking and slight cracking can randomly occur on the inside of creased products, often resulting in a visible white line either side of the crease bead.

‘Our research shows us that print companies accept that certain materials are much more brittle than they used to be, and that the slight imperfections of the inside crease result are something that just happens regardless of what creasing technology is used,’ said Mr Harris.

‘We saw an opportunity to try and change the outcome, and produced a simple solution to highly reduce and in some cases eliminate the defect. Our Tri-Creaser Advance works the inside of the crease in parallel with the outside, and simply fits onto our customers’ folding machines.’

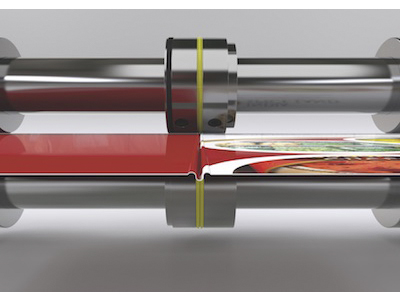

The solution involves matching “male” and “female” profiled creasing wheels and is very clearly explained by the video.

The Tri-Creaser Advance can be purchased as a full male/female solution, or just as a female retro-fit to existing Tri-Creaser Easy Fit & Fast Fit male collars.