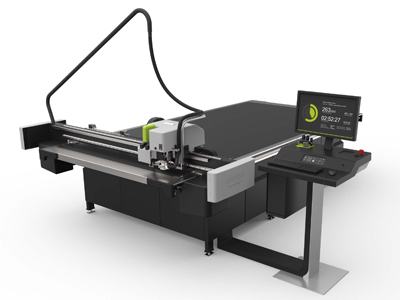

Esko Kongsberg X24 digital cutting table

Business expansion at Leeds-based Marshall Print required a new Kongsberg X24 digital cutting table, installed by CMYUK.

Marshall Print provides full service print production from banner printing, through vehicle wraps, to IPAF-certified installations. ‘Our clients know us as the first port of call for everything print, display and signage,’ says Martin Marshall, managing director.

To increase productivity, the company recently acquired a new Esko Kongsberg X24 digital cutting table with conveyor belt.

The X42 is upgradeable and features four vacuum sections and a work area of 1680 x 3200mm. Using Kongsberg’s Shared Resources functionality, the i-cut Production Console analyses incoming files and automatically selects the right tool, the correct table settings and the ideal cutting sequence for faster, more consistent production. Marshall Print also took up the conveyor feed option, enabling automated sheet or roll feeding of materials for faster workflow.

‘Installing the new Kongsberg X24 could have caused major disruption in a busy production schedule, but the CMYUK team set it up with the minimum of fuss,’ said Mr Marshall. ‘It was quickly integrated into our workflow and instantly began to earn a return on our investment. I would strongly recommend the X24 as the perfect cutting and finishing solution.’

‘Customers such as Marshall Print are looking for simplified and streamlined processes that can be adapted as the business grows,’ commented Robin East, CMYUK managing director. ‘The Esko Kongsberg solution provides just this.’