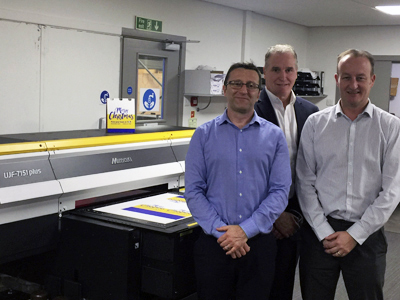

(L-R) Phil Knight, Falconer pre-production manager; Steve Beswick, sales manager for wide format products at Production Print Direct; Richard Martin, Falconer MD

Yorkshire-based Falconer Print & Packaging has installed a Mimaki UJF-7151 plus LED UV flatbed printer from Production Print Direct Limited to improve carton proofing quality.

The company, which specialises in luxury and pharmaceutical packaging, was encouraged by the Mimaki’s potential to complete jobs too small and time-consuming for their Heidelberg press.

‘Not only was the bed size of 710 mm x 510 mm ideal for the Iggesund board size we use, having the ability to print on to a thickness of up to 153 mm offers us a lot of future flexibility,’ explained Richard Martin, Falconer MD. ‘The inks are flexible too, which means that no cracking in the finishing process occurs.’

‘Our customers’ needs and expectations on turnaround and what we can print on are constantly keeping us on our toes,’ added Mr Martin. ‘The Mimaki has stunning print quality with ink drop placement at 1200dpi which is a massive improvement on the toner based kit it replaces. We spec’d it with white and clear inks to give us the full effect for proofs that require spot UV varnish with a very tactile finish.’

‘Falconer had already recognised they needed to improve their proofing capability,’ recalled Steve Beswick, sales manager for wide format products at Production Print Direct. ‘We ran a few jobs at the Crewe showroom and the UJF-7151 plus offered more than expected, especially being able to lay down multiple layers of process, white and clear using the six staggered print heads, producing a spot UV varnish effect in a single print process.’

‘Customer feedback has been great,’ noted Phil Knight, Falconer’s pre-production manager. ‘It’s rare to get comments for proofs but there’s been a lot of praise for what we send out which has improved both job approvals and increased orders.’