Swigraph’s new PZ dies can punch two different profiles for improved efficiency

Swiss manufacturer Swigraph has introduced a new method of punching normal sheets, or halfboard covers with its auto-punches, where one die now carries two rows of pins to punch two different profiles.

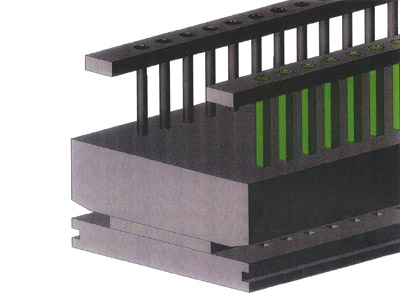

This new concept is offered in HD dies that fit in the Series PZ-420 & PZ-501 automatic punch series of 420 mm or 500 mm work-width. These PZ dies carry two rows of pins (instead of only one) and allow the user to insert them sideways in the auto-punch machines, simply presenting the chosen row of pins to appear at the ‘sheet-entering side’ of the machine.

The exchange of dies in the PZ-auto-punches is said to be extremely easy, taking only 2-3 minutes. To do a 180-degree ‘turnaround’ of the PZ-dies (front row to back row of pins), the die is pulled out from its bed (no screws or bolts involved) and inserted again from the opposite end in the machine – so that now the back-row of punch-pins appear toward the front, sheet-receiving side in the machine.

The buyer is of course free to choose any combination of punch profiles in the die to suit the requirements of the job.