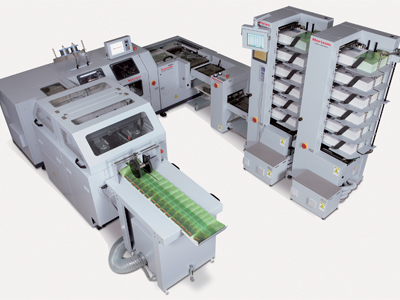

Horizon StitchLiner

FE Burman has opted for a Horizon StitchLiner and an Uchida Aerocutcutter, creaser and perforator, to elevate production quality and streamline productivity.

‘We recently invested in a second Indigo 7000 and that has increased demand on the finishing department, particularly for different job sizes,’ said Michael Burman, managing director. ‘We chose the StitchLiner to help us increase the level of quality of the product we were producing in both the final look and the security of personalised work.

‘We particularly liked the inline camera that supports the personalised work we complete. The new system means we can deliver the same products, faster, freeing up capacity. ‘

Another benefit is a flatter final product. ‘There is a regular 32 page, 10,000 run DL booklet that is machine enclosed. Not only is production smoother, it also looks better.’ Mr Burman added, ‘The combination of these factors made the investment right for us.’

The StitchLiner, supplied by Intelligent Finishing Systems, was chosen after a thorough review of what systems are currently available. ‘We looked at other options on the market and there were a number of reasons why we went for the StitchLiner. The three knife trimmer was very robust and heavy duty and the HOF feeder allows you to stitch collated products and that helps with flexibility. It is also easy to use and quick to set up.’

He was impressed by the feature advances introduced on fully-automated 11,000 bph Horizon StitchLiner that include a high profile icon-based colour touchscreen for set-ups in less than two minutes. Also expected to help with job turnaround is the instant job storage and recall, ideal for short runs.

The company also invested in an Uchida Aerocutcutter, creaser and perforator.

Featuring a user-friendly colour display for simple and easy job setting, it features an Upper Belt Air suction system and Uchida Ultra-Crease to prevent toner cracking. It also has Cut Register Mark Detection and can accurately feed stocks to 350 gsm.