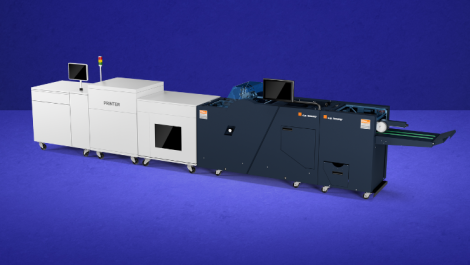

Pioneer 400

To meet the demands of fast turnaround short to medium run digital bookbinding, Newbind has doubled the productivity of its Adventure and Pioneer closed tank, PUR perfect binders.

Marketed in the UK by Encore Machinery, both binders have a new improved closed tank PUR glue head with auto cleaning for reduced operator maintenance, very little glue waste and no need for ventilation or fume extraction. The closed tank system also prolongs the life of the PUR glue, allowing up to 20 reheats before the glue needs changing. The running speeds have now increased from 200 cycles/hour to 400 cycles an hour.

New features also include an operator friendly colour touch screen as standard, together with automatic spine length calibration, in addition to the auto book thickness facility. This means that every book can be a different thickness and have a different spine length without any setting or input from the operator.

Together with the end sheet lifting device, which is ideal for producing book blocks for hard case book production as the end sheets can be attached to a book block with side glue on both sides of the end sheet, these Newbind PUR super compact binders now represent a new level of productivity for the digital print market.