Harrogate-based Platinum Print has invested in a Horizon AF-566T4F B2+ fully automated all-buckle 6/4 folder with a MKU-54 reversible mobile knife unit from Intelligent Finishing Systems.

The latest investment follows the commissioning of the UK’s first four colour Komori Lithrone S429 with H-UV drying technology. Director Mark Plummer said, ‘Our existing folding system was old and we were sending work out due to capacity and complexity. Without a doubt the investment was made to improve our productivity.

‘The quick makeready is the biggest advantage particularly with short runs. It saves us up to 20 to 30 minutes per job. It has made a significant impact by enabling us to complete more jobs inhouse and take on more complex work. This is especially the case for folded multi-section work which we would have sent out. It is also highly accurate.’

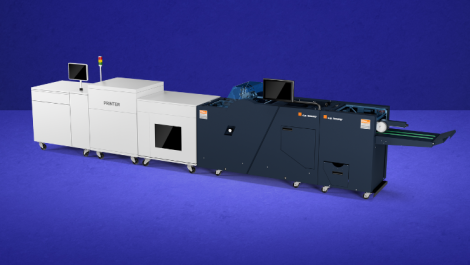

The AF-566T4F is a JDF-ready fully-automated B2+ system is equipped with 6 buckle plates in the first unit plus 4 buckle plates in the second unit and a MKU-54 reversible mobile knife unit, enabling a wide variety of fold patterns. Roller gaps are calculated by the intelligent computer control from the single sample of stock placed in a master calliper. Operation is via a user-friendly, icon-based intuitive 10.4″ colour touchscreen.

The company has also invested in a Horizon GFB-56 gate fold buckle plate to produce closed double gate fold work, a AF-ST5N Strip Trim Device for two-up work, as well as the MKU-54 reversible mobile knife unit suitable for all Horizon AF/AFC-folders. It can also be connected with Horizon bookletmakers to endorse fold booklets for mailings.

‘We use this to feed off the Horizon StitchLiner 5500 saddlestitcher for endorsed folding which helps our customers make significant postage savings and keeps us ahead of the competition,’ Mr Plummer concluded, ‘We have increased the folding department’s workload because we are able to deliver more options. We can keep all folding inhouse and offer a wider range of options. To demonstrate what we are capable of we are producing a promotional booklet with a closed double gate fold. This is something we would not have been able to do before.’