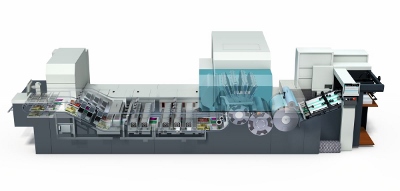

A cutaway view of the Jet Press 720S.

At a briefing held at its Advanced Print Technology Centre in Brussels, Fujifilm has released information about the ‘second generation’ of its B2 inkjet press, the Jet Press 720. The briefing also saw the announcement of new versions of its XMF Workflow and XMF Remote software.

A simple look at the headline specifications for the new Jet Press 720S shows little advance from those of the original press, which Fujifilm announced in 2008, with commercial availability following in 2011. It remains a four-colour sheetfed digital inkjet press capable of printing up to 2700 B2 sheets per hour at a top resolution of 1200 x 1200 dpi, using water-based pigment inks.

There has, however, been a good deal going on under the bonnet that Fujifilm contends will make the 720S a much more productive press than its predecessor when real numbers are added up. With the intention of maximising press uptime, advancements include a modified mechanism to feed paper onto the drum, a paper height safety detection system to reduce the risk of paper jams, and a significantly enhanced printhead cleaning regime. The printheads themselves are Fuji’s own optimised SAMBA heads, with a new modular design that allows for individual modules to be replaced when necessary in three hours, rather than an entire bar of heads needing to be replaced, which can take days.

VersaDrop technology gives users the opportunity to vary the drop size from the printheads, down to 2 picolitres. Modifications have been made to ink jetting order to reduce artefacts between dots, the print drum surface and paper vacuum control. The Jet Press 720S remains a single-sided machine, but Fuji has developed some sort of compromise it seems – what it called ‘secure semi-duplex print’, involving printing a barcode on the non-image area of the first side of the sheets, which are then turned over, re-loaded and the barcode read to ensure front and back page matching.

‘We’ve tried to design this press so that the overall printing process is much more efficient,’ said head of European communications Graham Leeson. ‘The Jet Press 720S has a bigger sweet spot which goes right into longer runs. It fits the emerging world of high quality, short run printing that is complementary to offset. We believe there are significant opportunities for printers to make money from this press.’

The company said that five of the second generation Jet Press 720S presses have already been ordered in Europe, though none yet in the UK.

On the software front, the latest release of XMF Workflow is version 6, while the web portal system XMF Remote has reached version 10. Fujifilm is seeking to address issues such as the greater number of jobs that printing companies are processing today and the increasing numbers of those jobs that require a high level of RIP processing. XMF Workflow v6 is built on the Adobe PDF Print Engine 3 and is also the first workflow in the world to incorporate Adobe’s Mercury RIP architecture, which has been developed specifically for digital printing. Both of these factors result in dramatically improved file processing times, Fuji claims. The system can load balance by processing each page of a job simultaneously during rendering; it can cache common or repeating elements of a job to reduce processing time.

‘What benefits most from this is variable data work, especially when using complex graphics,’ said Fujifilm Europe business strategy manager John Davies. He added that XMF Workflow v6 has full support for PDF/VT – the file format developed specifically for variable data and transactional jobs. Everyday use of PDF/VT is still low however, which he said was due to there being few workflow systems available that can process it. ‘We need to make more case studies and share them so that people can see the benefits of using PDF/VT,’ Mr Davies said. ‘The value of it is in creating marketing materials that are much more graphically rich.’

XMF Remote v10 meanwhile is now completely based on HTML5, rather than Java, making its use with a wealth of different devices, including tablet/mobile devices, a much better experience. It also includes a new Remote Express feature, which makes it much easier for ad hoc work to be dealt with through Remote. Instead of requiring a username and password, customers are simply emailed a link to directly upload or approve jobs.