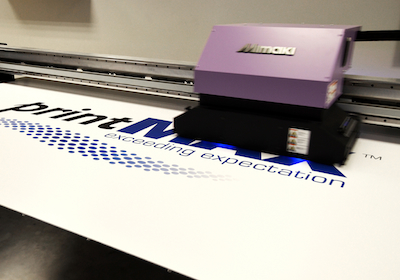

In a bid to streamline its production process, Weedoo Signs has purchased a flatbed Mimaki JFX200 to accommodate the rate of business growth it is currently experiencing.

The company, which specialises in the design, manufacture and installation indoor and outdoor graphics and signs, currently manufactures its products in a three stage process; printing, mounting and laminating. However, the JFX200 machine would take this three stage process and reduce it to one, as it prints directly onto the material required eliminating the need for mounting and laminating.

This results in producing a higher quality product, in far less time allowing the business to save both time and money.

The JXF200 is a productive flatbed machine, with print speeds of up to 25 msq/h and 12.5 msq/h with simultaneous white ink printing. It has a maximum print area of 2.5 m x 1.3 m.

‘Having estimated the work we can put through our Mimaki JFX200 in comparison to our current operations, we are confident that we are making the best investment in order to create a more efficient and profitable business going forward. We look forward to taking on much larger work in higher quantities!’ said Stewart Fox, Weedoo Signs.