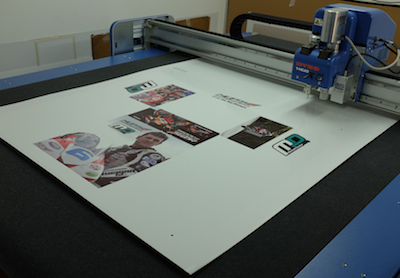

Image2Print has purchased a CNC cutting table from AG/CAD after the company found an increase in requests for packaging prototypes on various boards and flexible substrates.

As well as an increased interest in prototypes there was a demand for a stand-alone cutting and creasing service. The solution was found at the FESPA 2013 exhibition where the company bought the cutting table.

Company Director, Mr Foulkes said, ‘We increasingly noted a demand for cutting and creasing expertise. For some companies with cutting tables, print quality and reprographic knowledge was often an issue. A number of companies with cutting capabilities were also limited by the quality of their machines. We spotted a huge opportunity and reviewed the market for a solution.’

‘The result for is that we can now offer a complete packaging service to customers as well as the printing service. In fact, we have doubled the turnover of our packaging department since installing the DYSS machine. This is because the capabilities and flexibility of the machine enable us to complete a wide variety of jobs that we would have previously been forced to turn away. We are also expanding our customer base as a result of the DYSS acquisition,’ Mr Foulkes continued.

The company is now producing prototypes and small batch runs on the unit anywhere from 1 to 50 off on anything from FBB, B-Flute, E-Flute, Foamex and specialist boards.

Producing anything from frozen food and cereal boxes through to intricate cosmetic packaging, the DYSS has proved invaluable. Larger packaging and POS projects for large supermarket brands where precision and quality is a must are also possible.

Furthermore, the DYSS multi-head tool station can be configured for a reciprocating knife, drag knife or a kiss cut knife and a creasing wheel in any configuration unlike many alternative cutting tables.

In certain circumstances the high accuracy of the AG/CAD K-Cut Vision camera system allows jobs to be cut and creased from the reverse side of the board. Mr Foulkes stated, ‘We have found the K-Cut Vision system very easy to use and highly accurate. This enables us to cut and crease on the reverse side of the sheet when needed. The customer feedback on the quality of the cutting and creasing has been extremely positive. The combination of the K-Cut Vision System and the knife tools is excellent.’