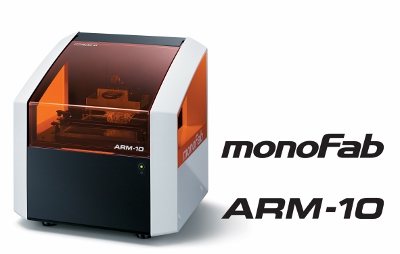

Wide format inkjet printer manufacturer Roland DG has released its first 3D printer, the monoFab ARM-10 additive rapid prototyping machine.

Launched at the same time is a milling machine, the monoFab SRM-20 3D subtractive prototyping and manufacturing machine. Both machines have a one year UK RolandCare warranty.

The ARM-10 3D printer is ideal for quickly checking a design in the initial stage of prototyping or modelling a complex shape. It builds models by sequentially curing layers of resin from a liquid resin vat. Simultaneous production of multiple objects can be accomplished within the same work area. Roland’s imageCure resin becomes semi-transparent when cured and post-processing procedures such as support removal (temporary parts that provide support during layering in order to prevent deformities or drops occurring)and polishing are simple to do.

The SRM-20 desktop milling machine incorporates several innovative subtractive rapid prototyping features, with its strengths lying, according to Roland DG, in providing outstanding accuracy and smooth finished surfaces. It can mill a variety of non-proprietary materials typically used for prototyping, including modelling board, acrylic, ABS, wood and modelling wax. An interlocked full cover prevents dust from escaping during milling.

‘The monoFab series desktop fabrication solutions are the culmination of over 25 years of experience in 3D milling and the company’s first foray into 3D printing,’ said Akio Kawai, Roland DG general manager of 3D market development. ‘By combining the merits of each device, users can select the best method for their workflow every step of the way, from inspiration to production. We hope the monoFab series tools will inspire those who wish to create the future and explore all their creative abilities.’