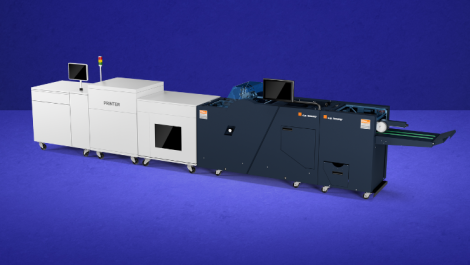

The Mailmaster 465HS

KAS Paper Systems is supporting Print Efficiently with mailing and addressing solutions and finishing equipment manufactured at their factory in Dunstable.

They will be demonstrating the ease of operation and quick changeover of the Mailmaster 465HS, which inserts into envelope sizes between DL and over-sized C4 at speeds of 6000 complete envelopes an hour. Additional features include sheet feeders with accumulation and folding in-line, OMR, BCR or 2D reading facilities, management information, in-line stapling and addressing.

For printers wanting to polywrap printed material, the Mailwrap processes pack sizes from A6 to over A4 at a throughput of up to 6000 packs an hour. It too combines performance with ease of use. The automatic flexible feeders handle single sheets, prefolded material and magazines or books.

Features include a close fitting wrap variable bag length, the facility to run printed or unprinted film and linking of feeders to increase loading capacity. Operation is through a touch screen which also displays run information. It is quick to set up with automatic heat settings for each run speed. Reading devices can be installed including exit reading, which along with the Data-Log software keeps a record of what has been processed.

The KAS CreaseMatic Auto 50 creaser, which is distributed in the UK through Ashgate Automation, is a high speed suction fed, fully programmable card creaser with a rotary perforating system. Stock can be creased in sizes from CD to SRA2 with four creasing width tools to cover the stock range of 80 to 450 gsm.