InnoMark Communications has selected EFI Radius ERP software to unify and manage business data and operations across its 11 facilities.

Fairfield, Ohio, USA-based InnoMark selected the packaging and converting ERP system based on its tools for streamlined, multi-plant management and the technical capabilities it gives users to direct an extensive range of finishing and fulfilment processes.

Radius ERP software, which will be implemented in phases starting later this year, replaces a series of programs and spreadsheet applications in use at the company’s various plants.

It was ERP implementation director, Joseph Roberts, who determined that Radius offered the best capabilities to unify the company’s decentralised business workflow structure.

‘EFI Radius’s multi-plant capabilities, and the ability it will give us to seamlessly transfer jobs between facilities, were key factors in our decision,’ said Mr Roberts. ‘We found that Radius had the most accurate and efficient technology for tracking revenue across plants, and that will help us better serve customers.’

Radius will be especially beneficial for managing many of the large, national retail signage and packaging jobs the company produces, as those jobs all transfer from different screen, litho, flexo and digital print facilities to a main hub for die-cutting, lamination, kitting and fulfilment.

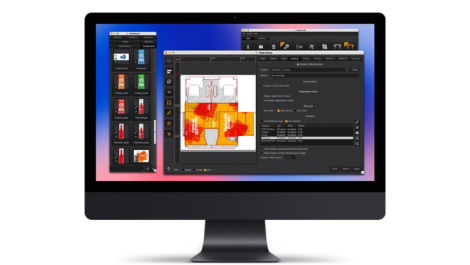

The software modules and features included such as Process Shipper software and integrated support for Esko ArtiosCAD 3-D design software, will allow the company to be even more prepared for its extensive finishing workload and complex fulfilment requests.

Streamlined scheduling and management across all of the company’s facilities will help reduce turnaround times and facilitate faster, more accurate billing. Radius software also will help the company enhance its sales and marketing efforts, ultimately creating a centralised platform for estimating and scheduling that will make it easier to compare print methods to find the best solution based on client deadline, budget or run length requirements.

EFI Radius inventory management tools, including shop floor data collection, will help InnoMark get substrates where they need to go for less press downtime. ‘Turnaround times in this industry are quick, so it was important that the solution we picked is strong in inventory management,’ Mr Roberts said. ‘If we need a particular type of board or a 100 lb. text (140 g/m2) stock in one plant and we have it in another plant, Radius will give us the information we need to identify those situations in advance, move substrates where they need to go and eliminate production delays.’

The company also will use the data it collects from its operations to give senior managers better, real-time information about operations using EFI’s award-winning Business Intelligence module. ‘The Business Intelligence module will be an important feature,’ said Mr Roberts, ‘because it will give us the big picture information we need to track down trends.’

With its robust technology for planning and managing nearly every converting, die-cutting, laminating, folding and gluing process, EFI Radius is the leading business software for the package printing industry. Those comprehensive features can provide substantial benefits for InnoMark – a leading print, fabrication and fulfilment provider that produces large-format, die-cut, laminated point-of-sale displays for some of the world’s best-known retail brands and performs high-volume folding carton and label converting work for the cosmetics, software/gaming and pharmaceutical industries.